LED Neon Flex

- Fully automated production, fast delivery time.

- Eco-friendly silicone and PU glue.

- LM80 compatible LEDs, up to 50,000 hours of life.

- Professional R&D team, support customization, ODM, OEM.

- 3 – 5 years warranty.

- Instant response to any of your inquiries.

LED Neon Flex Supplier & Manufacturer

LEDYi Lighting is one of top custom LED Neon Flex Strip Light manufactures in China. We offer customized solutions, OEM, ODM service. Wholesalers, distributors, dealers, traders, agents are welcome to purchase in bulk with us.

All our LED Neon Rope Lights are more than IP65 waterproof tested and certificated, ensuring high performance and long lifetime.

If you have customized need for bulk RGB LED Neon, LEDYi can offer custom LED Neon Flex Strip Light with custom color, size, long, CRI, and various accessories.

We can also provide a PCB level customized LED Neon Light solution. With our LED Neon light bulk order serivce, you can get as many projects as possible.

Contact us now for more information!

What is LED Neon Flex?

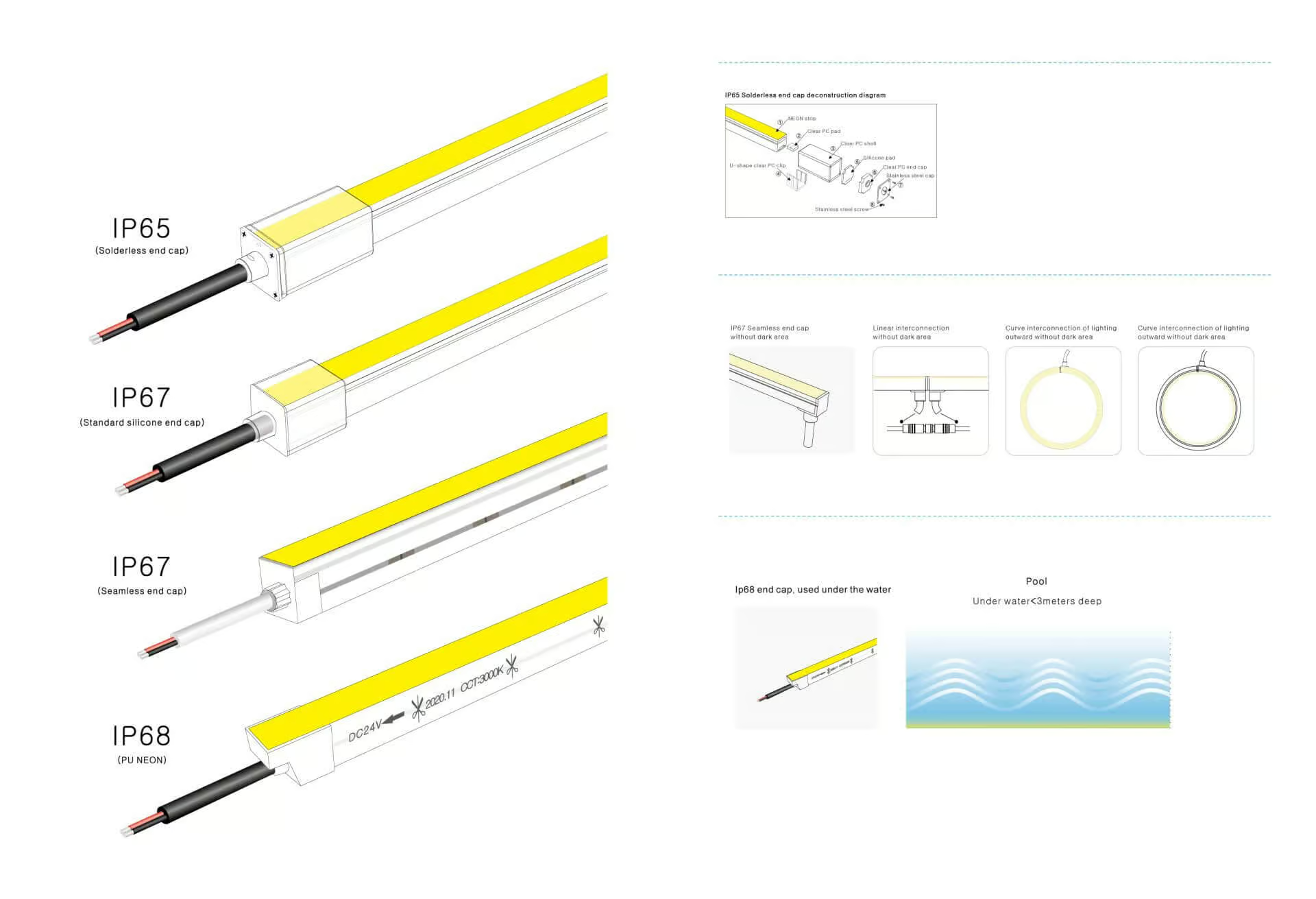

Neon flex strip contains silicone neon and PU neon. Silicone neon is IP67, used indoor or outdoor. PU neon is IP68, used underwater.

Silicone Neon is made by adopting three-color silicone integrated extrusion shaping process, and its protection grade reaches up to IP67, featuring resistances to saline solutions, acid & alkali, corrosive gases, fire, and UV, applying to indoor and outdoor molding decoration, building outlines, city night scenes illuminating, and so forth for the sake of the effect of decorative lighting.

PU Neon is made by TPU U shape milky tube and filling with opal PU glue. Its protection grade reaches up to IP68, UV resistant, and saltwater resistant, used for underwater decorative lighting.

Why LED Neon Flex Lighting?

The light source is made of LEDs, which can last up to 50,000 hours. The flexible silicone/PVC/PU gel is also used, so there is no problem breaking like traditional glass neon light.

Unlike traditional glass neon lights, which require a high voltage of up to 15,000V for regular operation, the LED neon flex light operates at 12V or 24V and is safe to use as it will not break and has low heat dissipation.

The dynamic colors of our LED neon lights uplift the mood and ambiance of any setting. Their rhythmic color-changing feature further enhances their decorative function

When you wish to mellow the mood or unwind, you can rely on our dimmable LED neon lights. Their settings are easily adjustable for comfort.

Unlike plain ordinary lighting, LED neon flex lights are far more versatile. They are suitable for both indoor and outdoor settings and provide vibrant lighting.

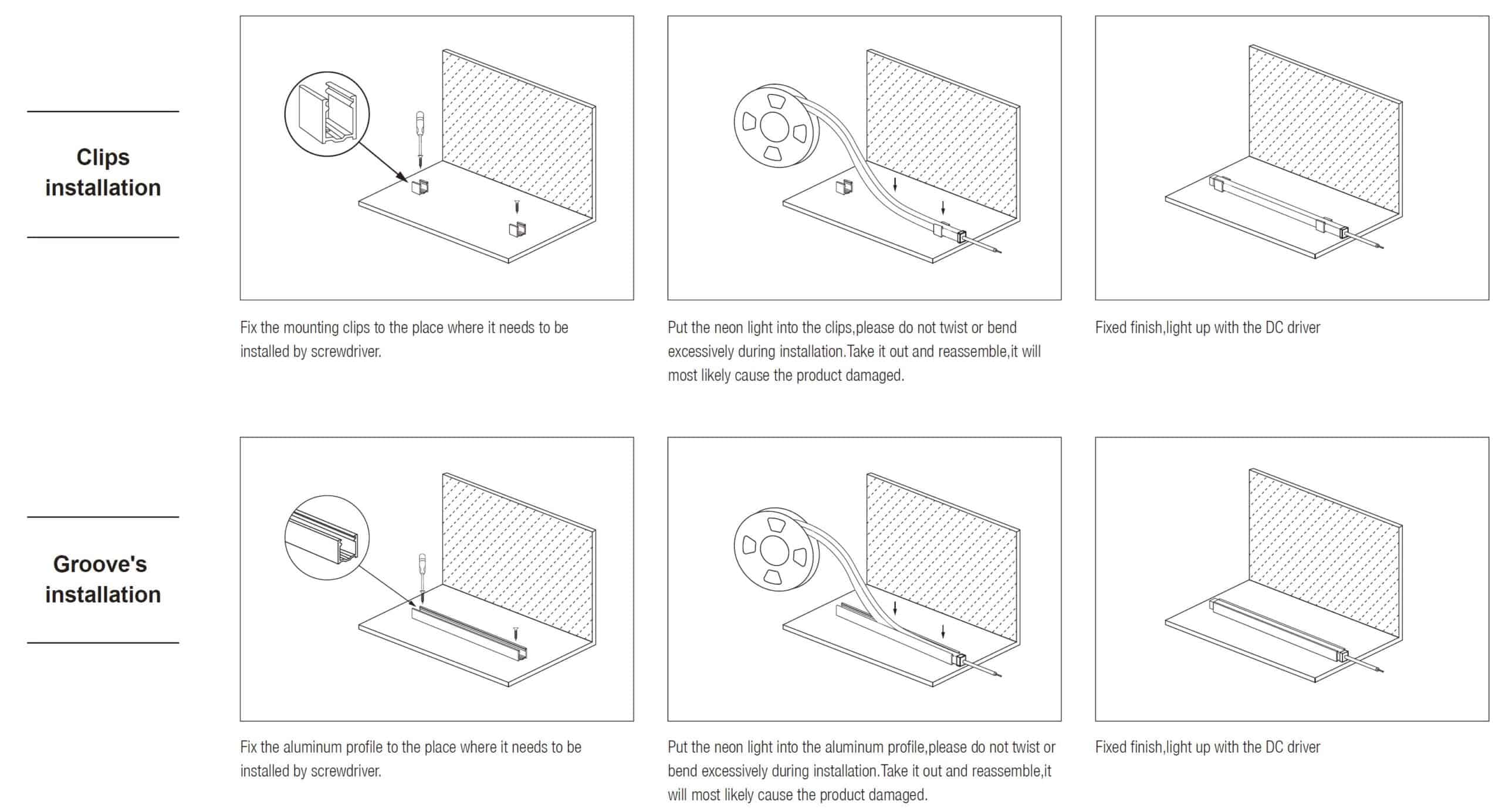

Because the light source is LED and the casing is PVC/Silicone/PU, it will not break during transportation. You only need to fix the mounting clips first or mounting channels, then press the LED flexible neon into mounting clips or mounting channels.

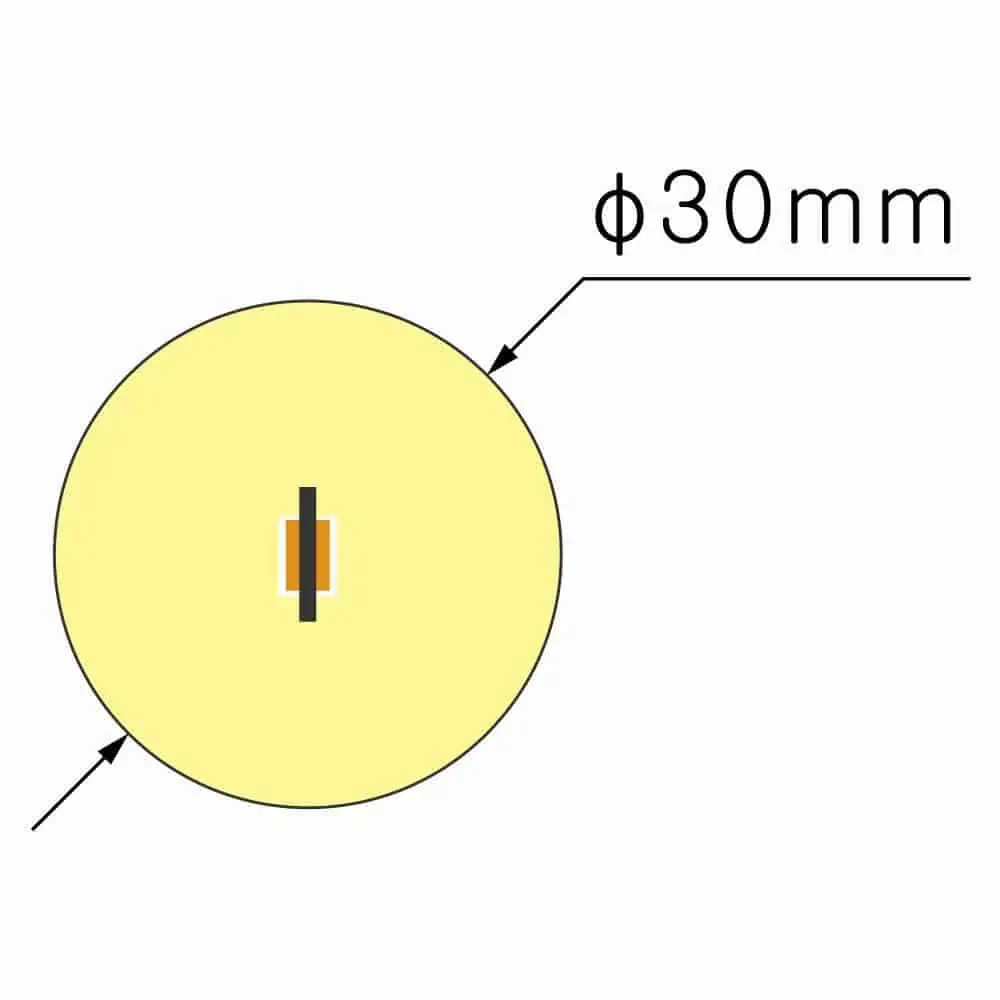

Flexible, the LED neon flex light can be bent to a minimum diameter of 5CM and sheared.

The light source is made of ultra-high brightness SMD LEDs, with a density of 120 LEDs per meter, ensuring high brightness and an overall uniform luminous effect.

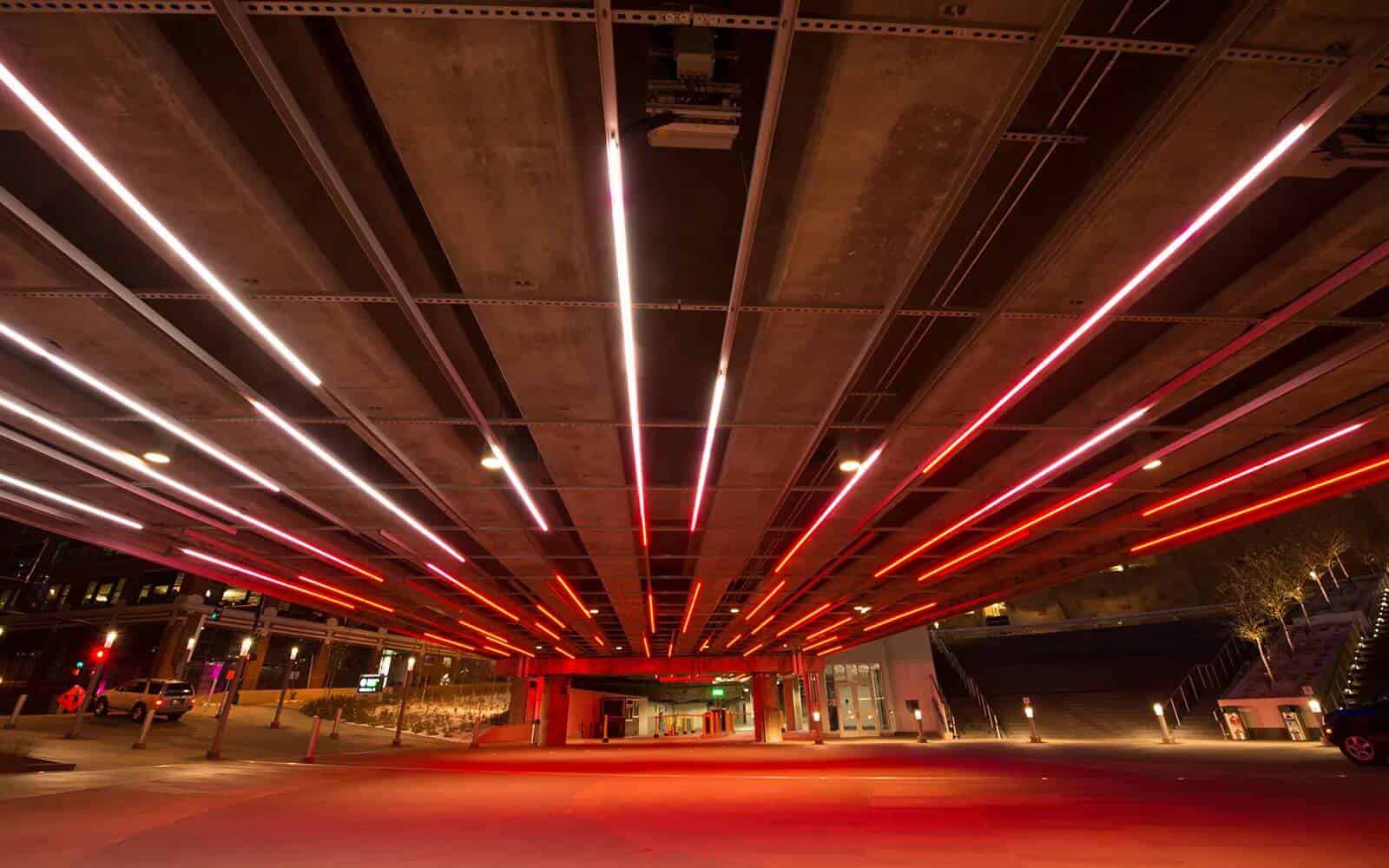

LED Neon Flex Lights Application

The applications of LED Neon Flex Lights are as follows:

1. Signage & Exhibit Lighting;

2. Building facades;

3. Cove lighting;

4. Retail displays;

5. Architectural lighting;

6. Marine Lighting;

7. Automobile Lighting;

8. Artwork Lighting;

9. Special Event Lighting;

10. Home Lighting

How to produce LED Neon Flex Lights?

The production process is divided into two main parts.

In the first part, the LED flexible strip is produced first, and the LED flexible strip is used as the light source for the neon lights. Please read “How To Produce LED Strip Lights?” if you need to know how to produce led strips in detail.

The second part is to add the silicone shell to the LED strip. There are two main ways to add the silicone shell. The first way is LED strip and silicone integrated extrusion. The second way is to produce the silicone tube first and then put the LED strip into the silicone tube manually.

LED strip and silicone integrated extrusion process

Step 1. Mixing silicone

Step 2. The extrusion process begins with installing rolling LED strips on the payoff frame. These LED strips are adjusted and sequenced using an adjustment table.

Step 3. The LED strip and silicone are then passed through the holes in the pre-assembled die, activating the operating button on the electronic control box, which starts the machine to wrap the silicone onto the LED strip.

Step 4. The machine extrudes the silicone-coated LED strip and passes it through the vulcanizing oven, where the product is gradually vulcanized and shaped. The temperature inside the oven is kept moderate to avoid burning the LED beads. After vulcanization, the led neon is put out by a tractor.

Please read “The Ultimate Guide to LED Neon Flex Lights” if you need to know how to produce LED Neon Flex Light in detail.

How to cut and connect LED Neon Flex Lights?

Cut & Connect By Soldering

Step 1. Measure the length

Step 2. Find the cut position on the LED Neon Flex

Step 3. Cut the led LED Neon Flex

Step 4. Cut off some silicone from the LED Neon Flex

Step 5. Soldering cable to LED Neon by electric iron

Step 6. Fill silicone in LED Neon and endcap

Step 7. Light up the LED Neon to test

Step 8. Wait for the silicone to dry and solidify

Cut & Connect By Solder-free Plug

Step 1. Measure the length

Step 2. Find the cut position on the LED Neon Flex

Step 3. Cut the led LED Neon Flex

Step 4. Attach connectors to LED Neon

Step 5. Connect the power plug to LED Neon

Step 6. Light up the LED neon to test

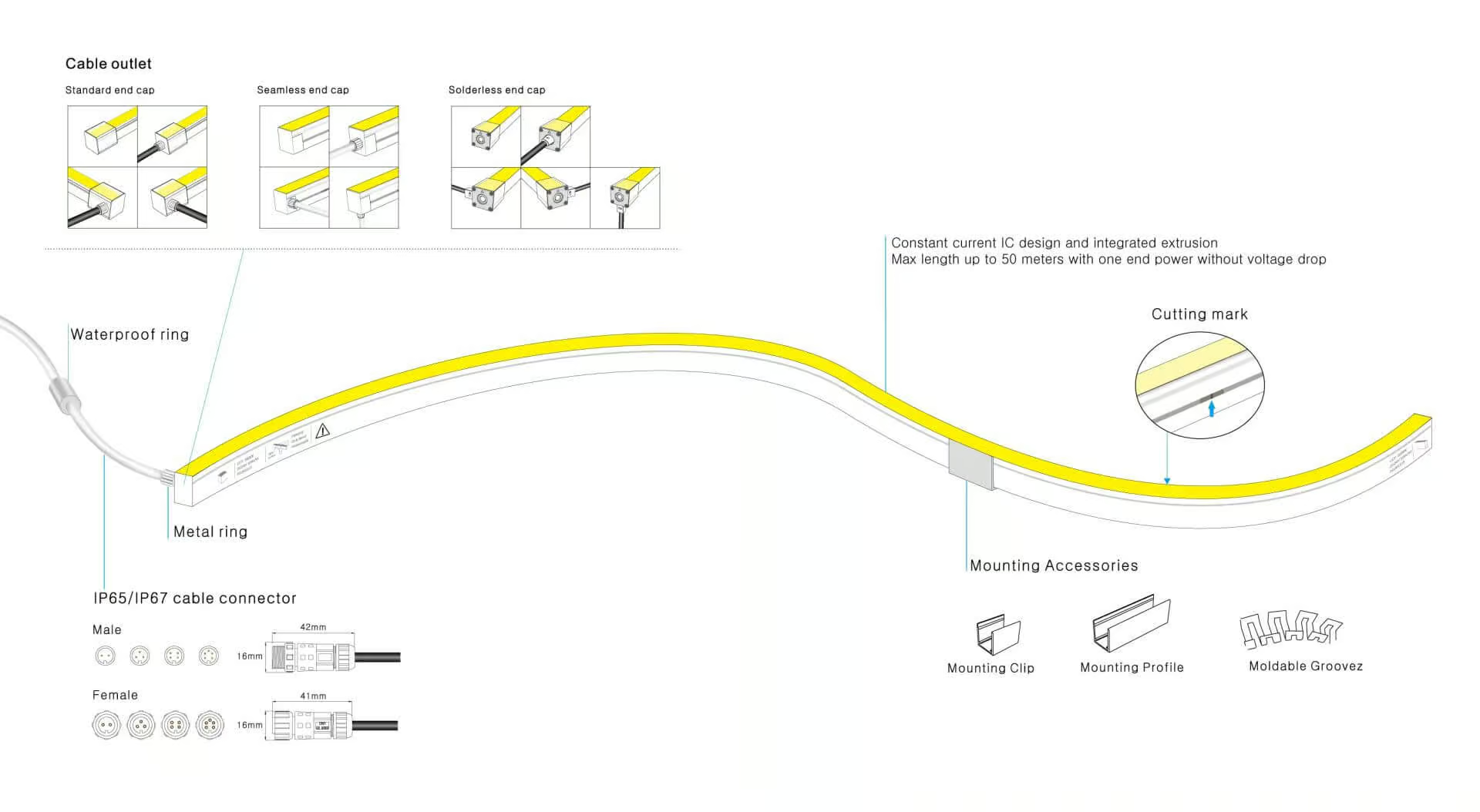

2nd Generation Solderless Endcap

The 2nd generation silicone neon solderless endcap does not require screws, and is more convenient to use.

LEDYi LED Neon Flex Solution

LEDYi provides various LED Neon Flex standard and customized solutions and OEM, ODM services.

IP Grades: IP65, IP67, IP68

Endcaps: Silicone Endcap, Solder-free Endcap, Seamless mold injection endcap

Different Cable outlet: Side, Bottom, Straight

Mounting Accessories: Mouting Clip, Mouting Channel, Bendable Mouting Channel

Connectors: IP65/IP67/IP68 Waterproof Connectors

CC/CV: Constant Current can be up to 30 meters per reel, Constant Voltage can be up to 5 meters per reel

Power Consumption: 5W/m, 10W/m, 15W/m for your choose

Wholesale LED Neon Flex Strip By Series

Get custom LED Neon Flex Strip Light that match your exact needs from LEDYi – one of the leading custom LED Neon Flex manufacturers in China. From simple to complex PCB designs, our skilled designers and engineers can answer your needs at affordable prices. We allow you to customize the following features:

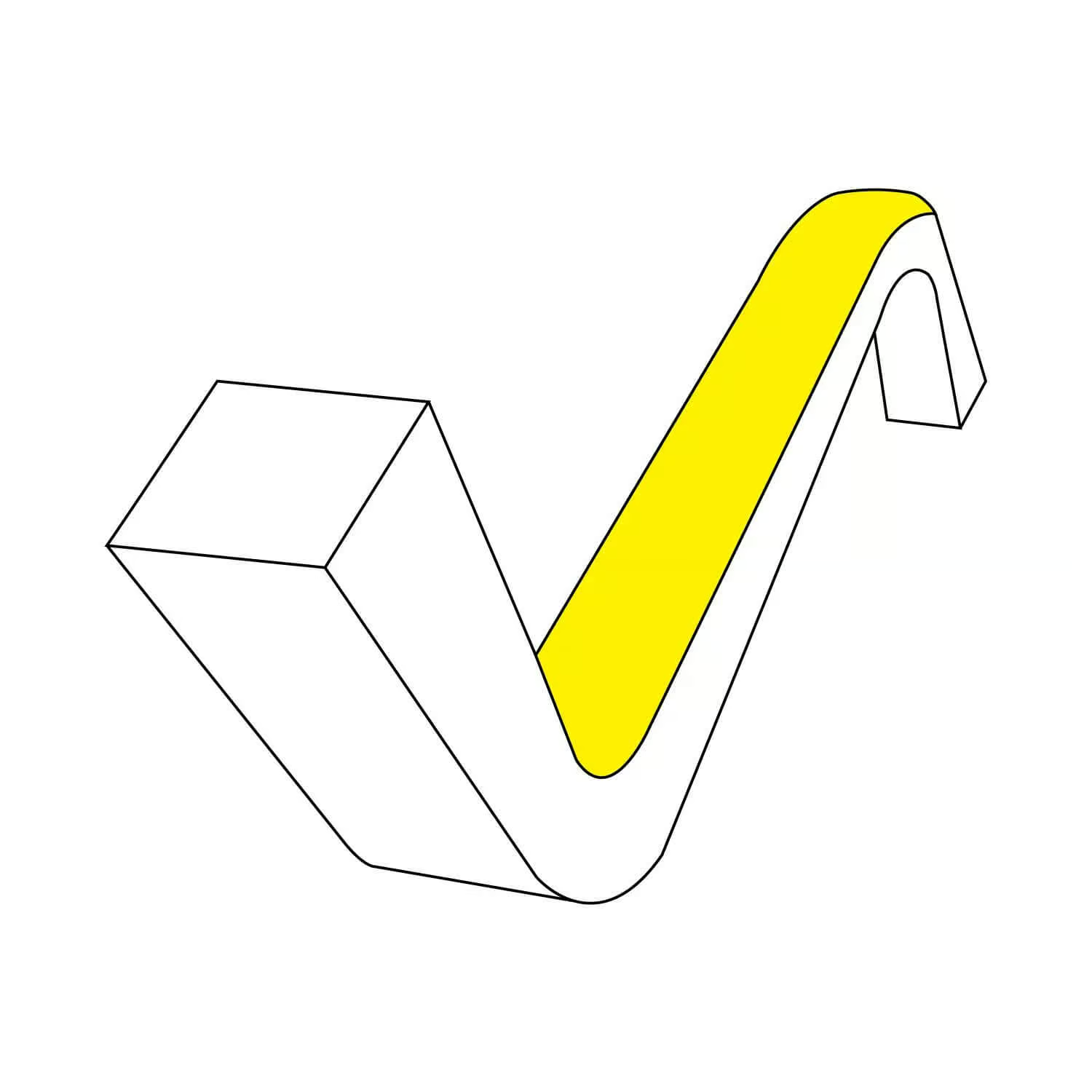

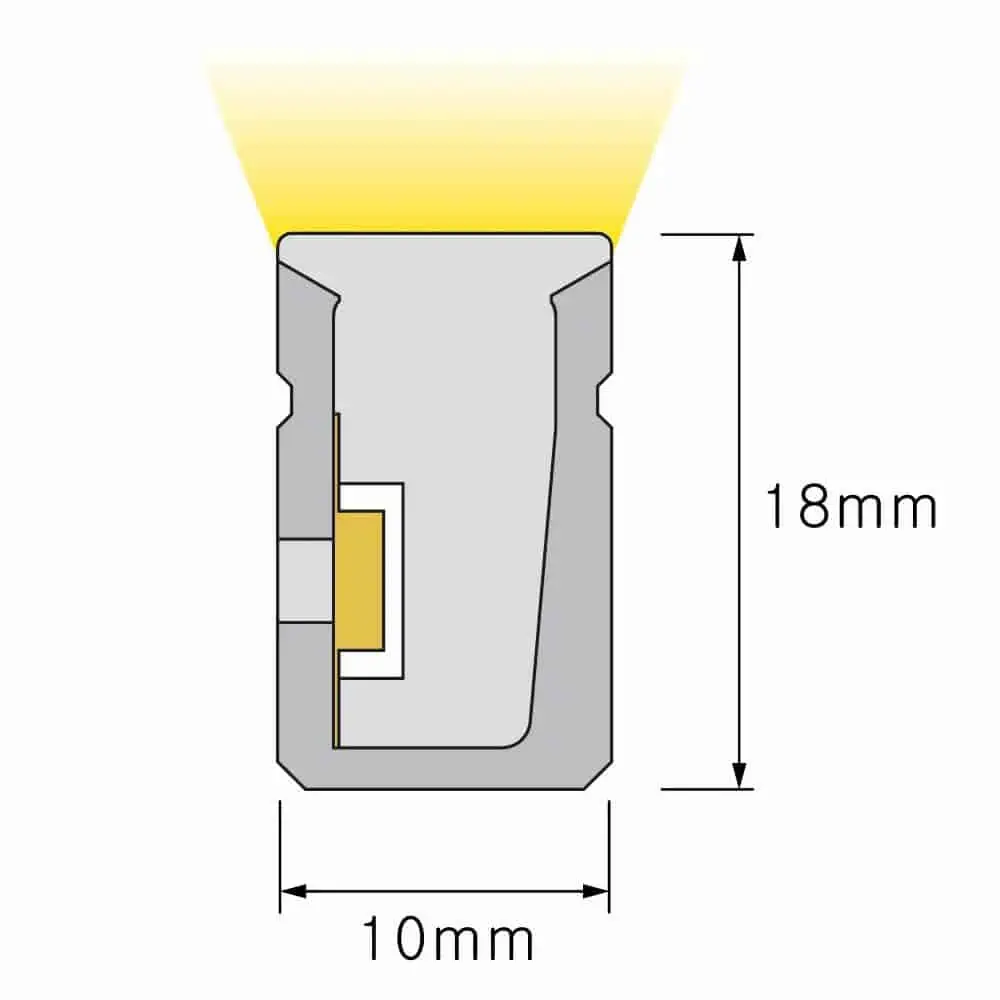

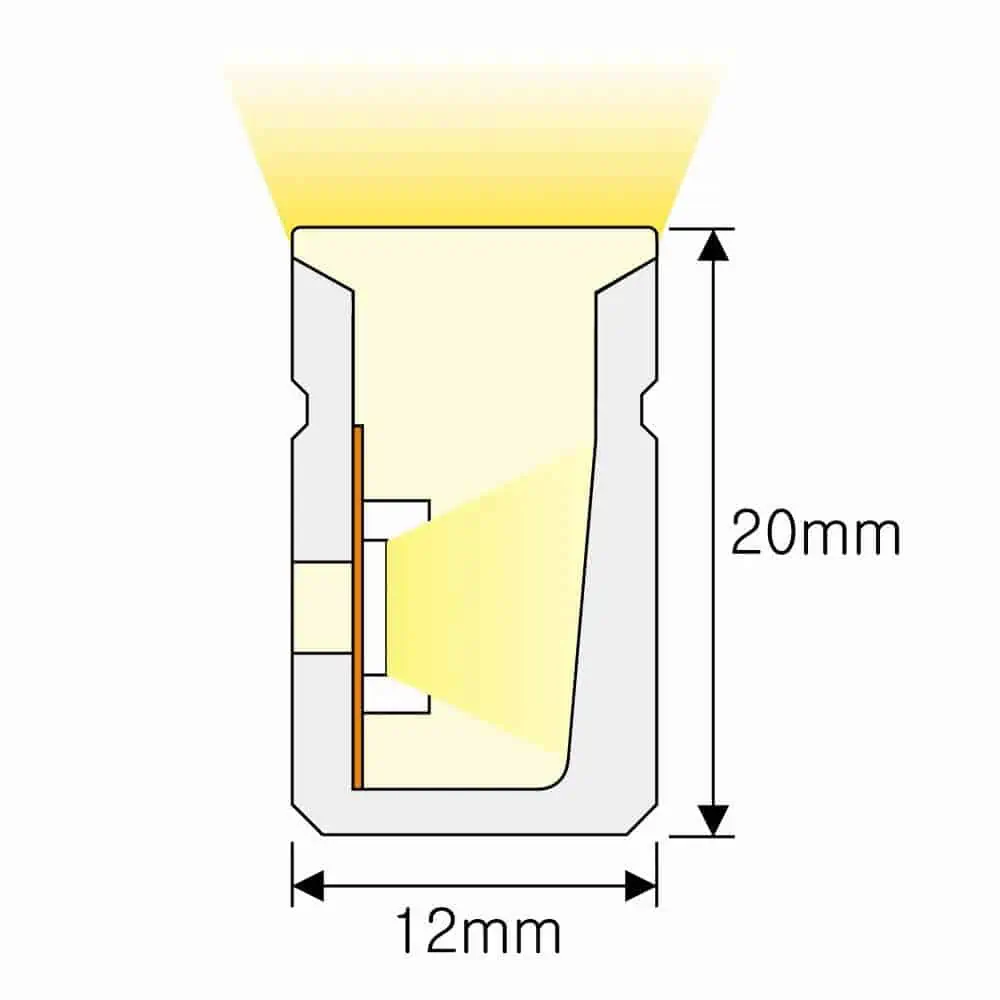

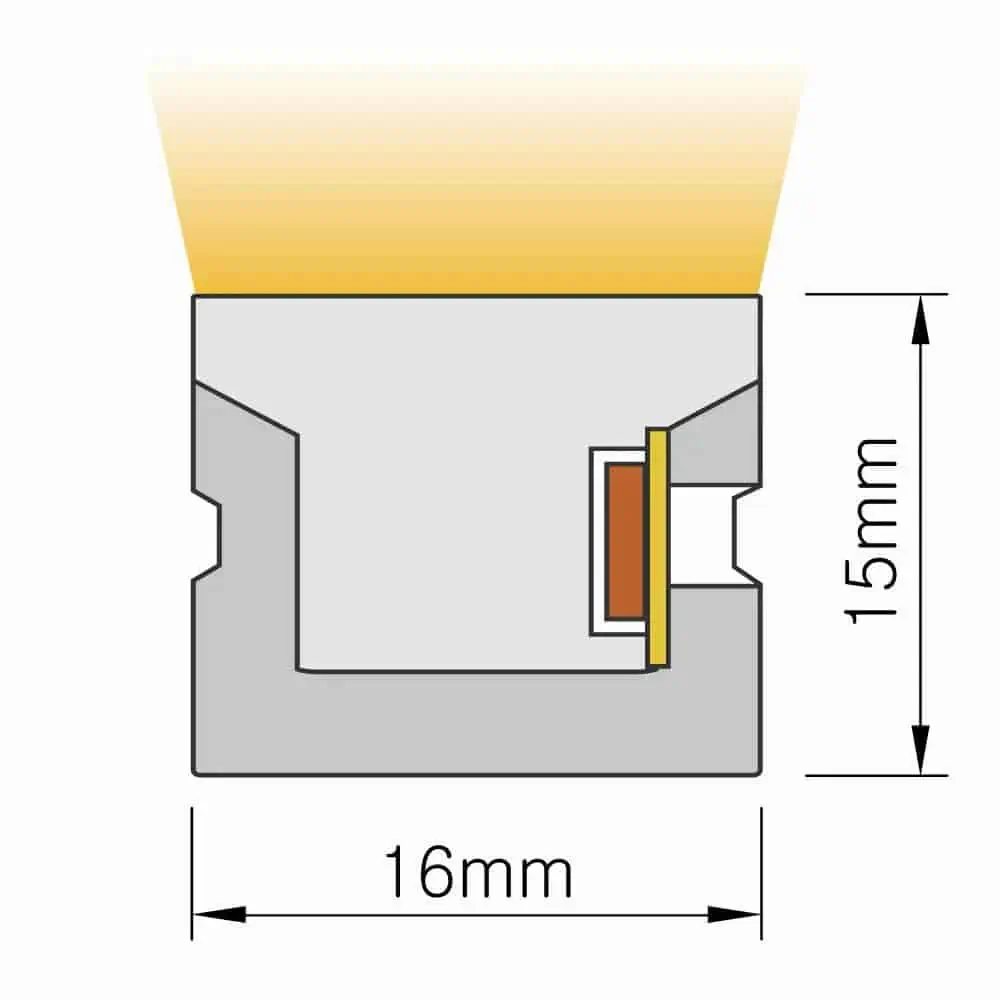

Vertical bend series neon flex strip adopt environmental silicone material, up to IP67 protection level, even if used outdoor for a long time, the surface will not turn yellow easily. High light transmission, can be used for sign lighting, indoor and outdoor decorative lighting and architecture contour lighting molding. After “9 major tests”, it is resistant to hydrochloric acid, acid and alkali corrosion, flame retardant,UV resistant, reliable and guaranteed quality.

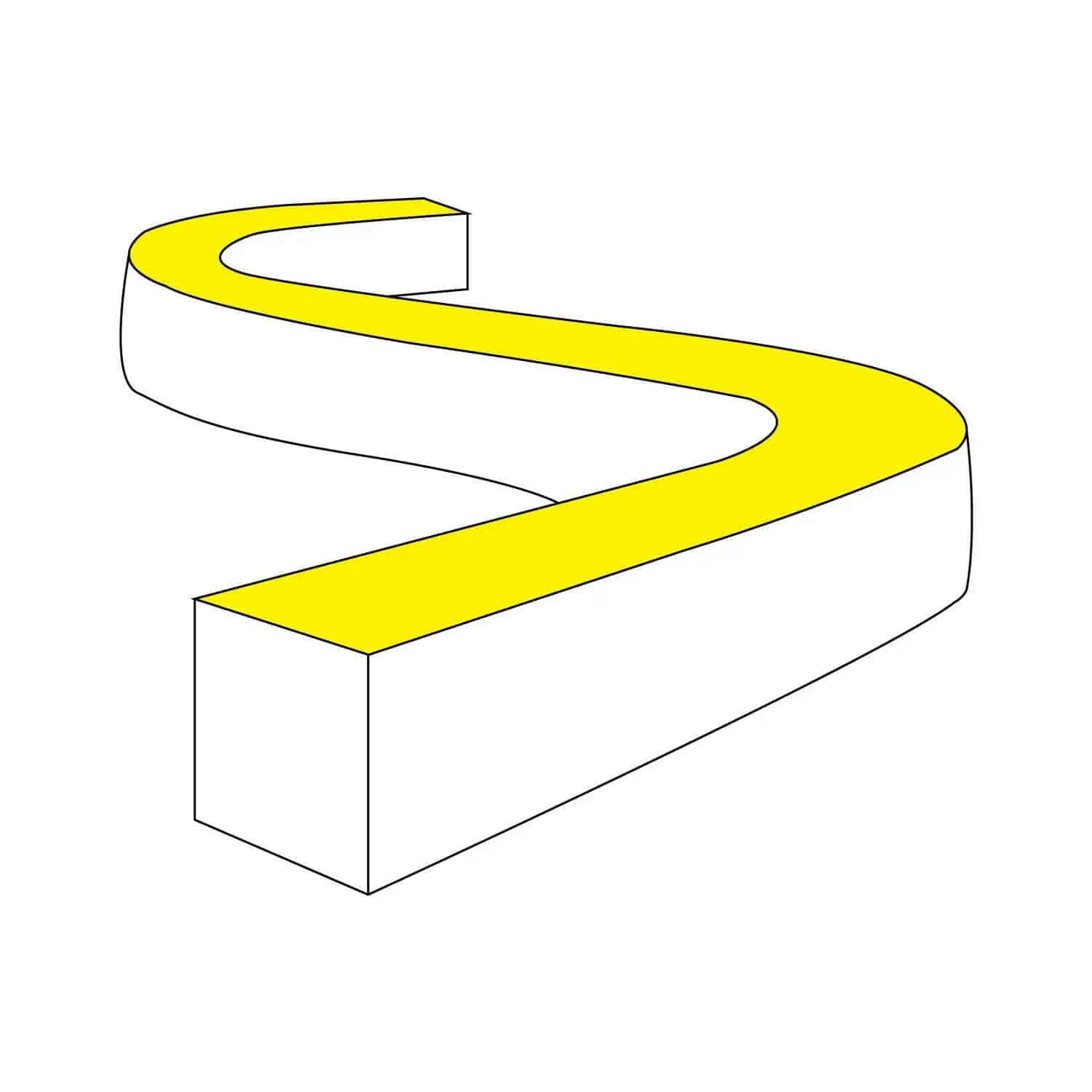

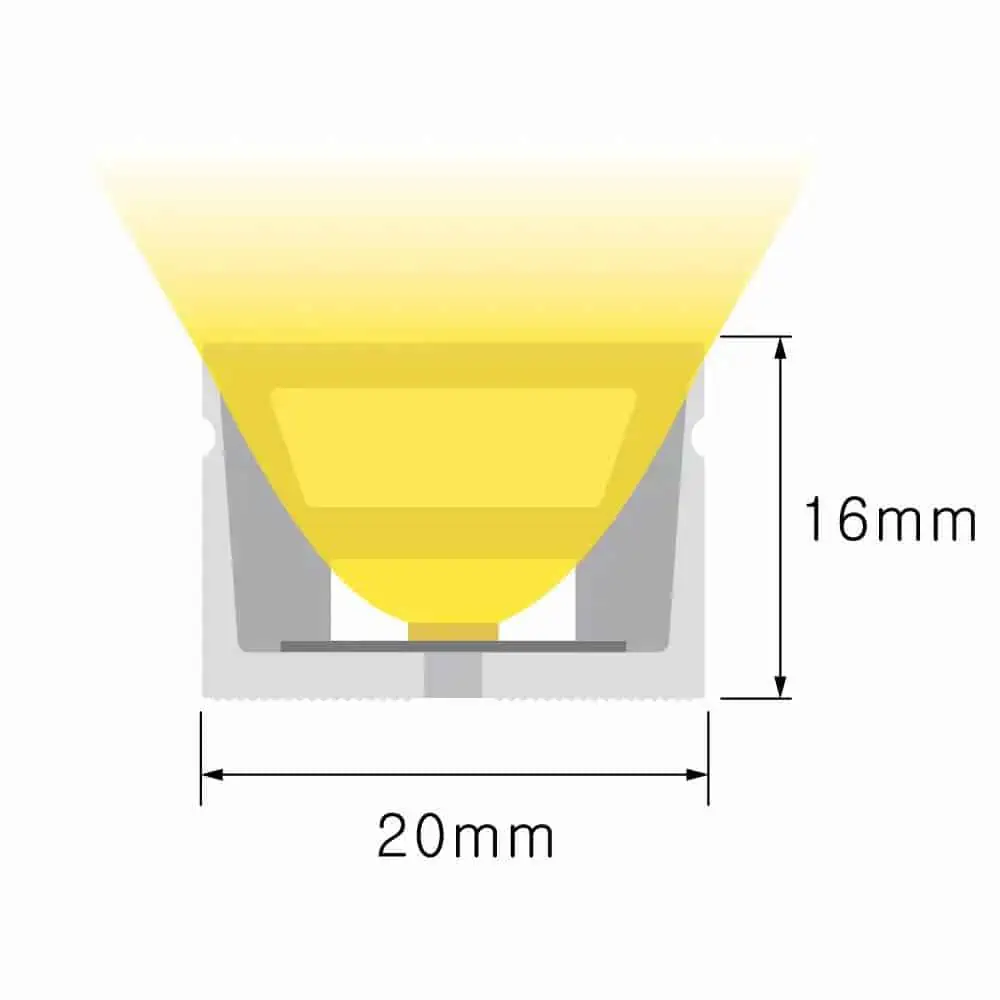

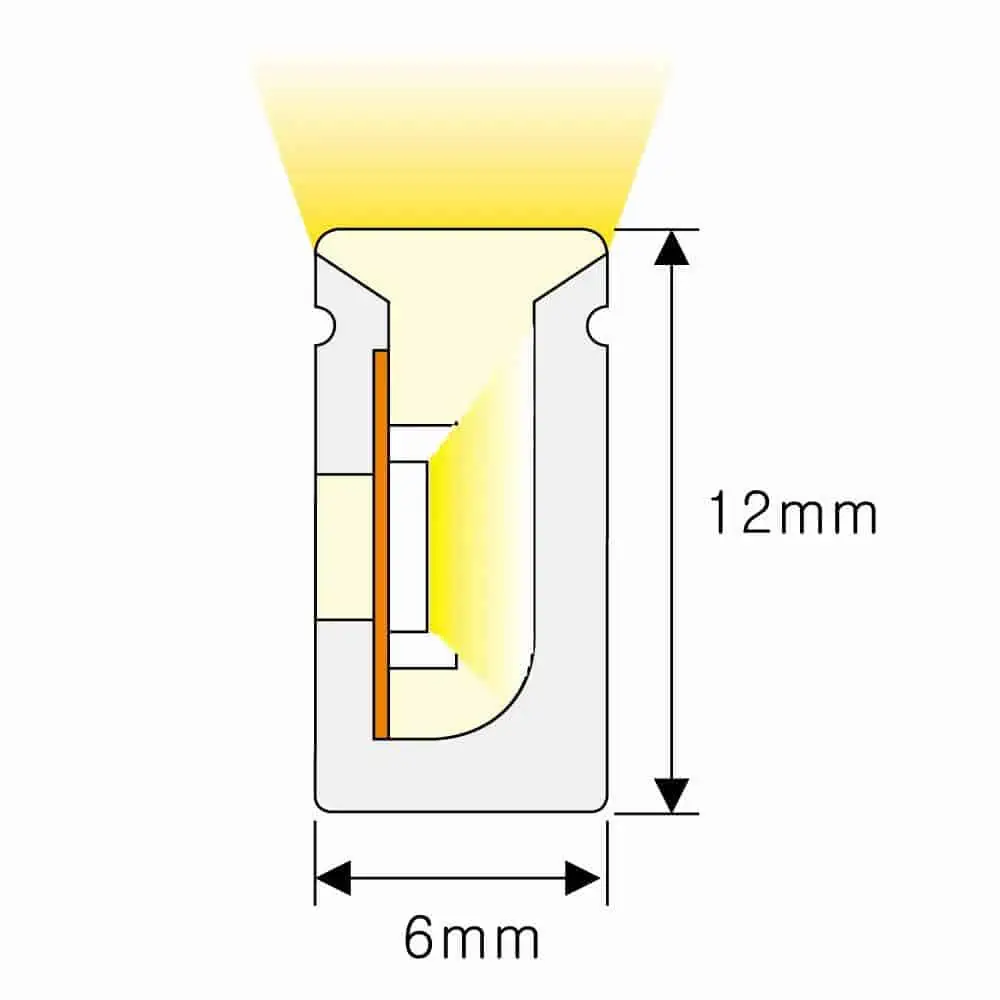

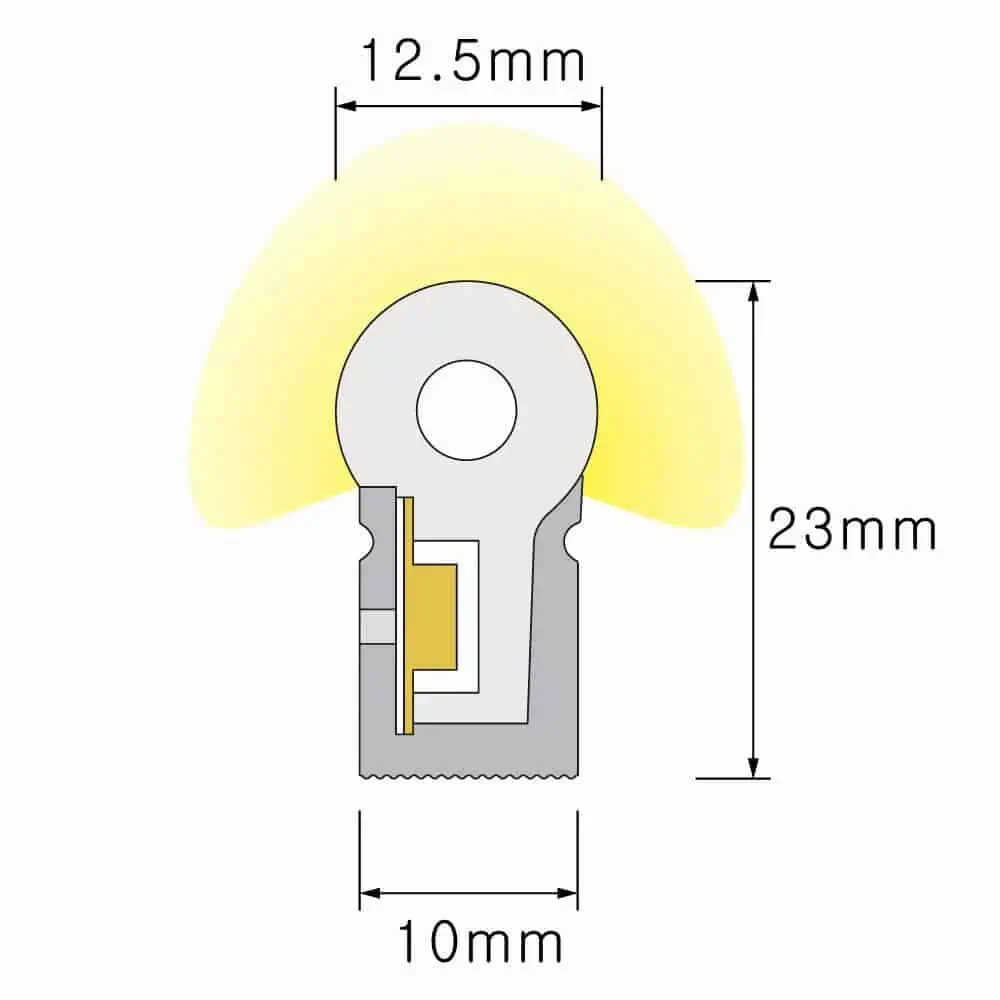

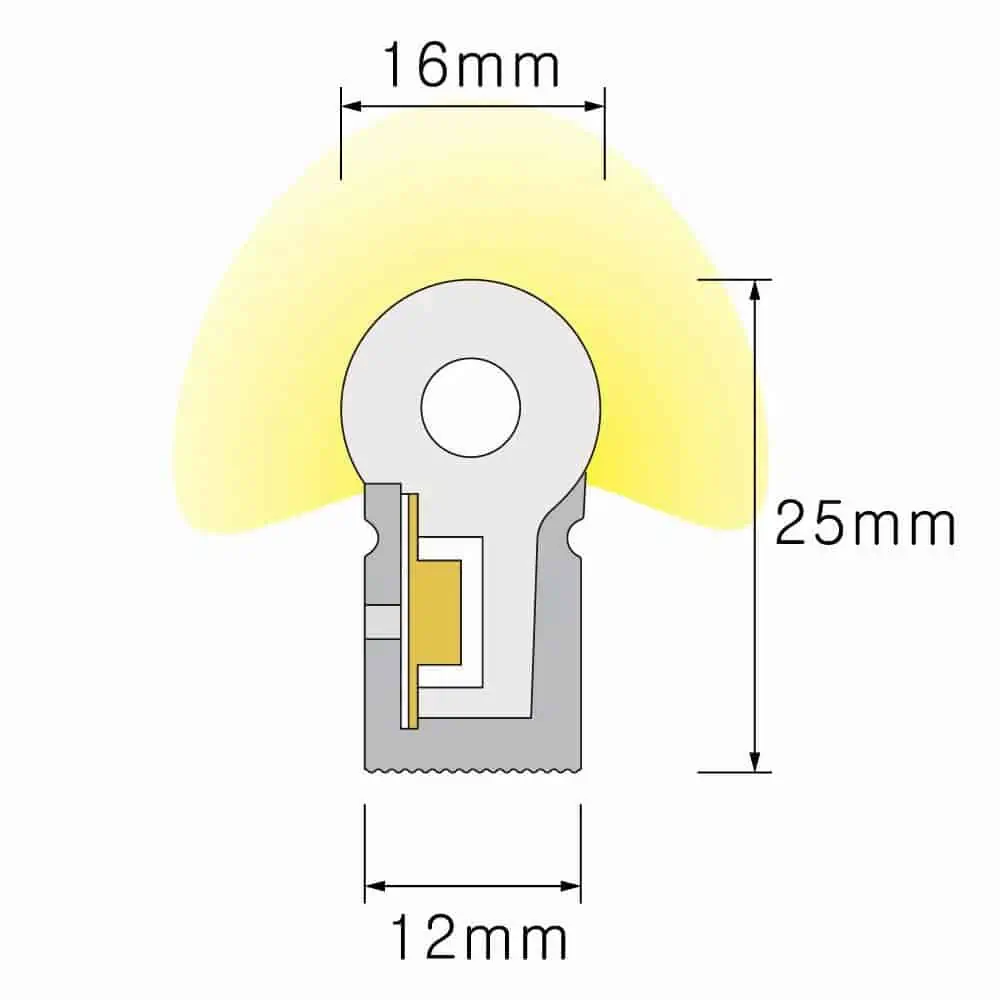

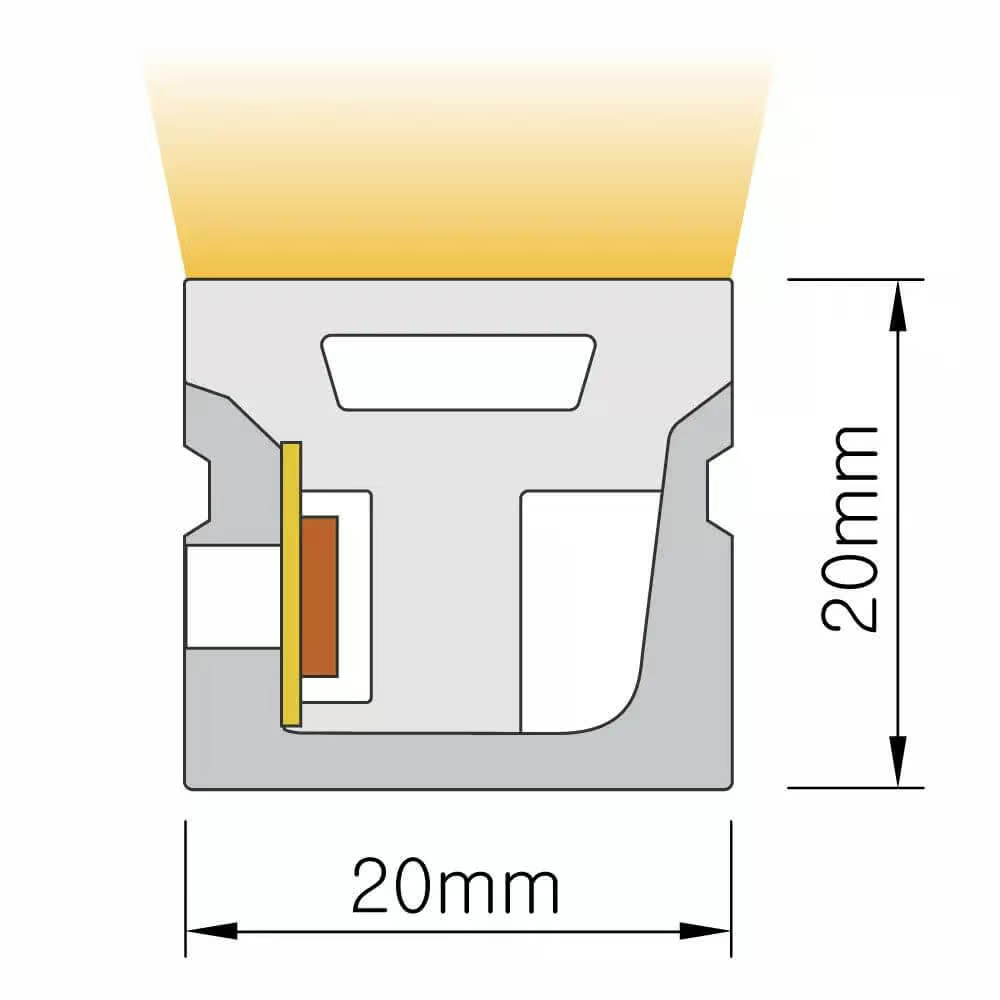

Horizontal bend series neon flex adopt unique optical structure design, uniform light and no shadow. Horizontal-bending design can be used for building outline, indoor and outdoor decorative lighting and other scenes. IP68 high protection level, suitable for swimming pool underwater lighting. Passed CE, Rohs and other international environmental protection and reliability certifications, product quality is trustworthy.

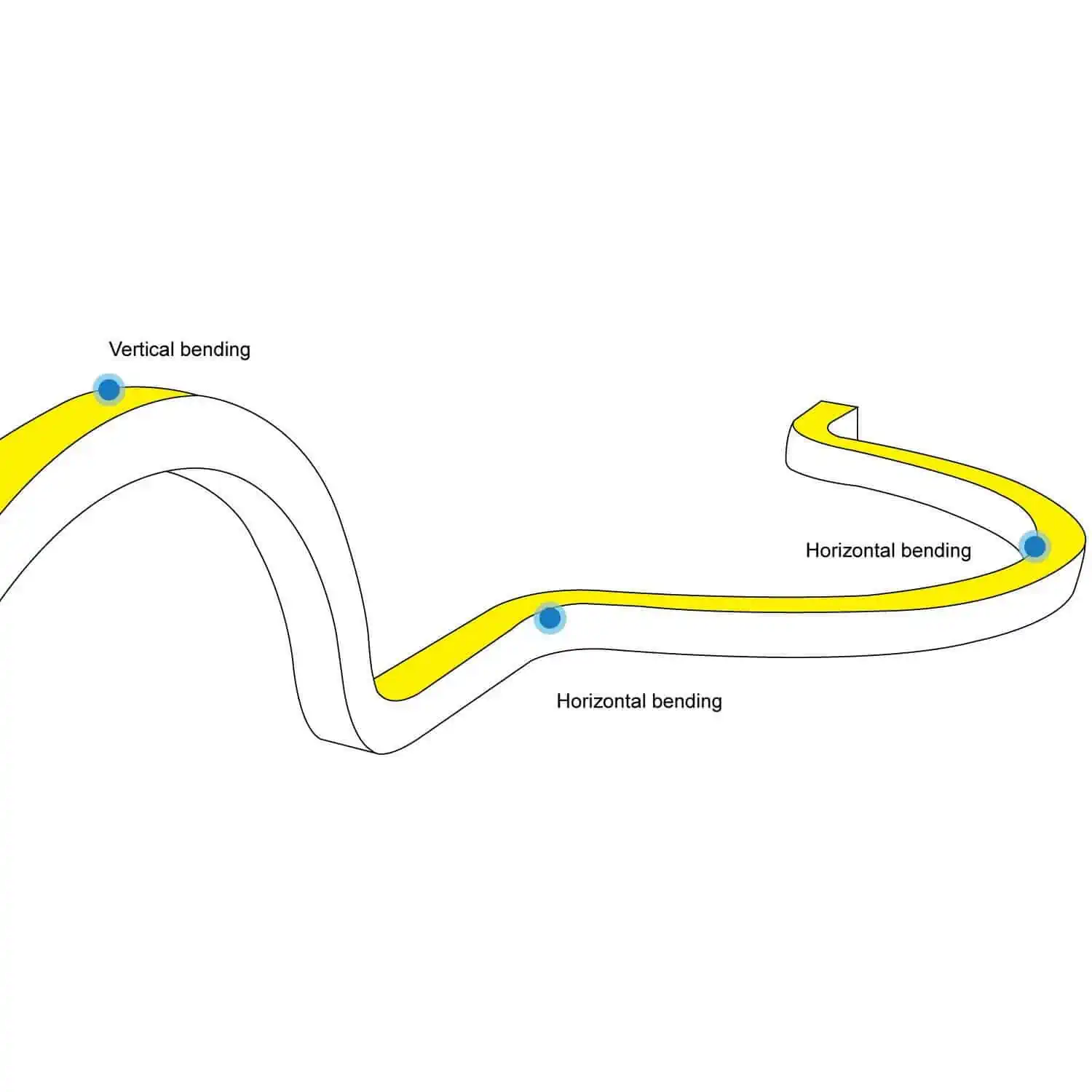

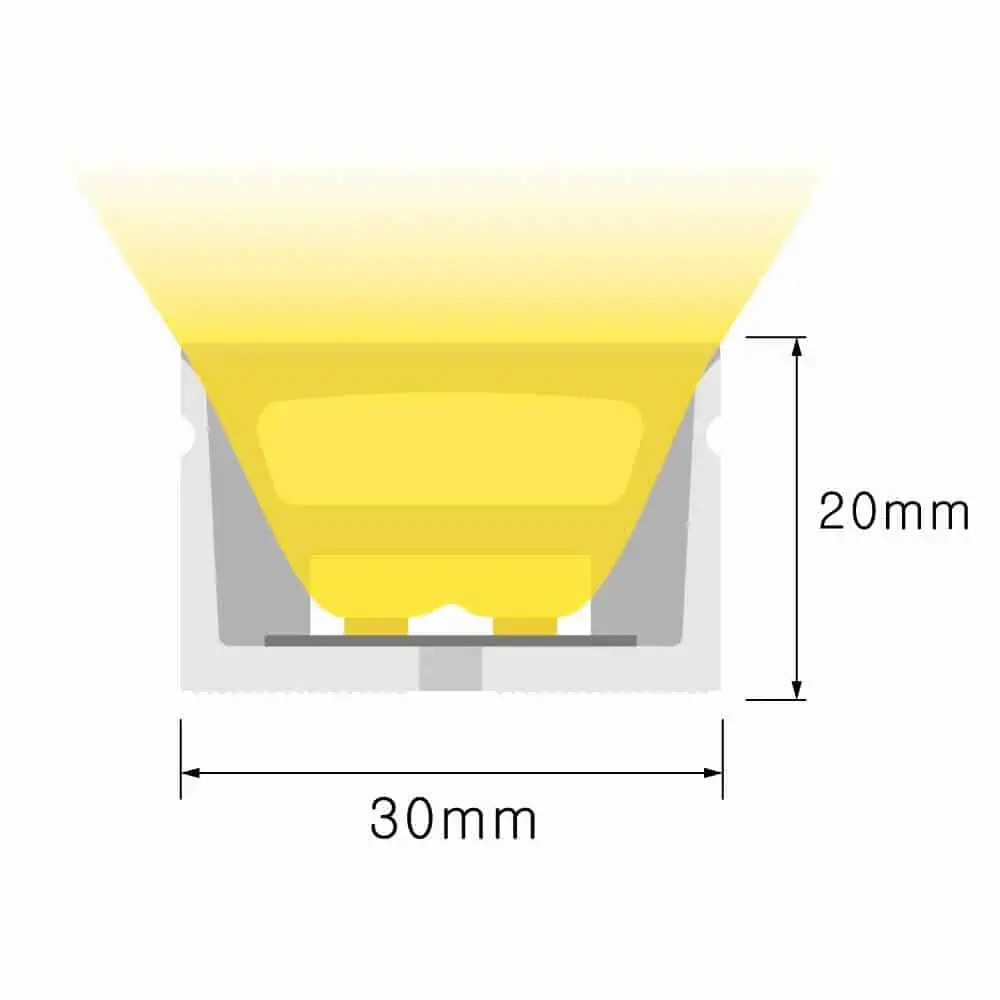

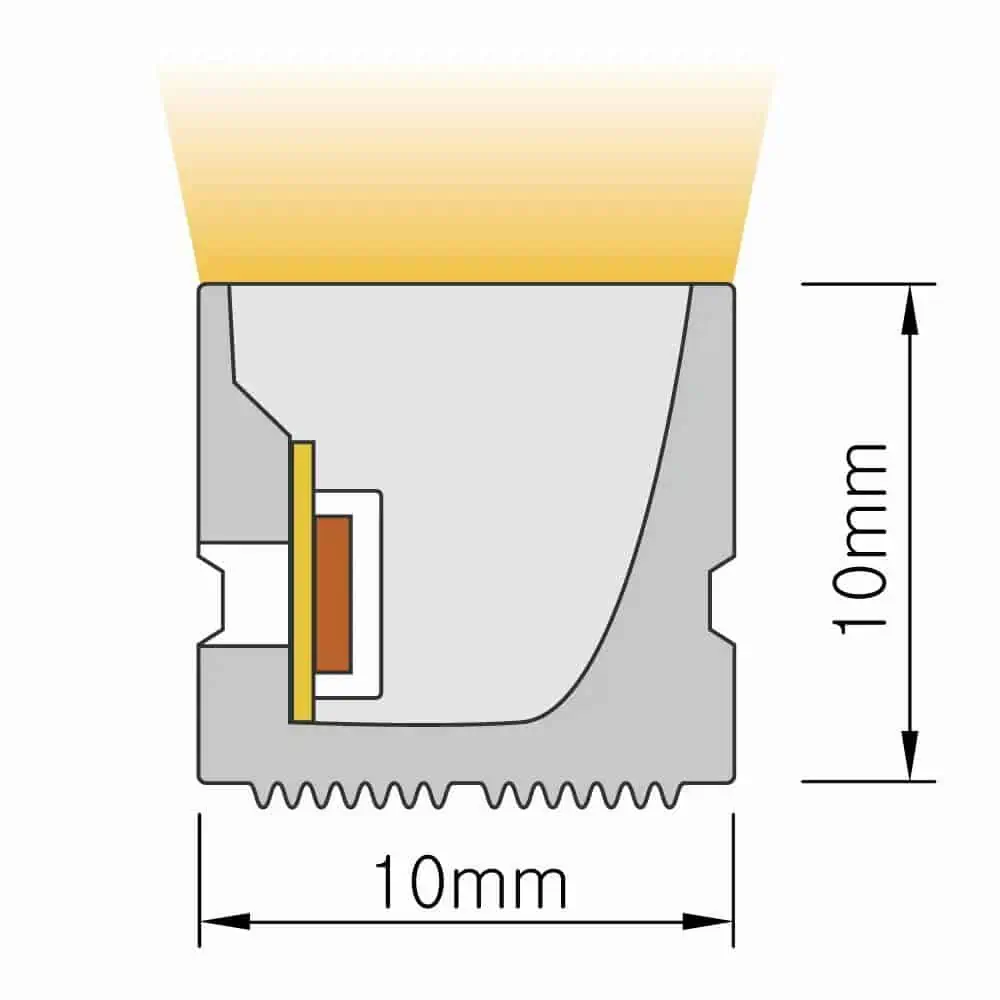

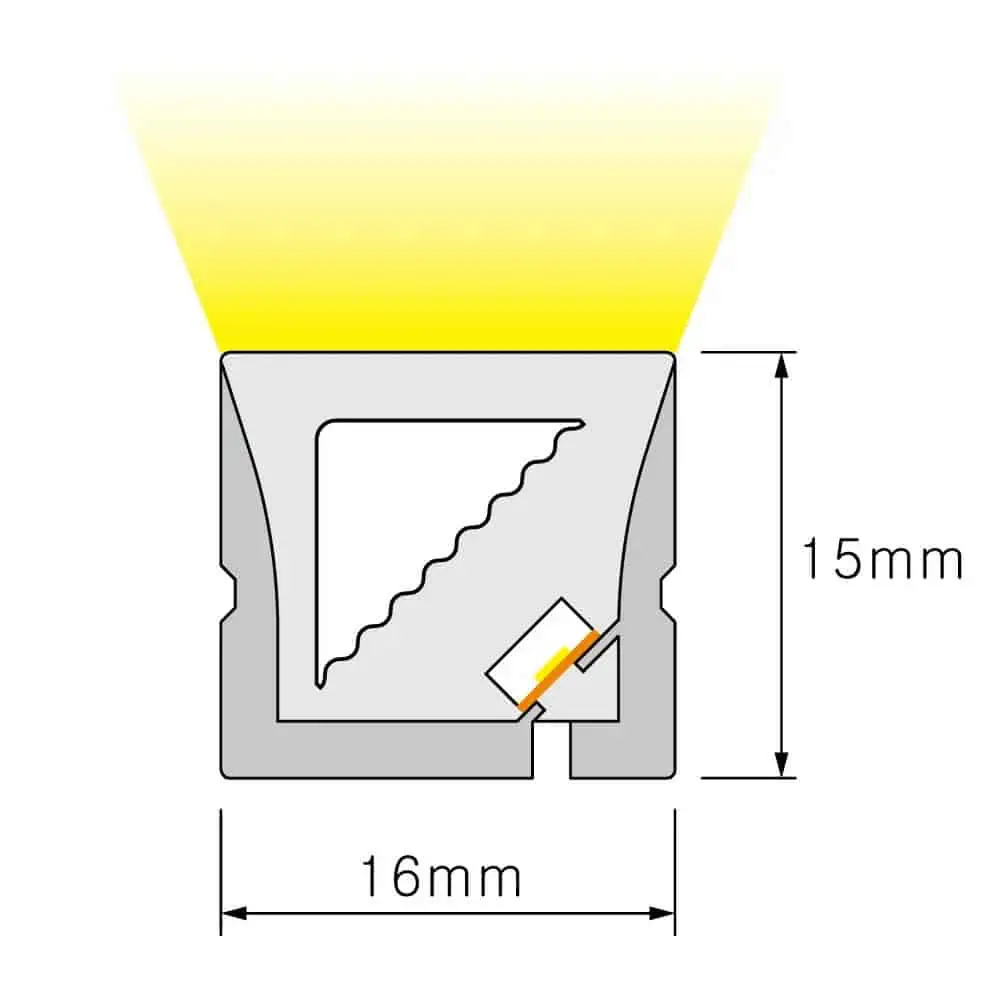

3D bending series neon flex adopt flexible silicone material,strong plasticity, combined with vertical-bend, horizontal-bend two type lighting surfaces, and the matched installation solution, meets the needs of multiple lighting. Silicone coextrusion process, IP67 protection level, no fear of indoor and outdoor humid environments, meeting the lighting needs of indoor decoration, landscape lighting,architectural curtain walls, building outline and other scenes.

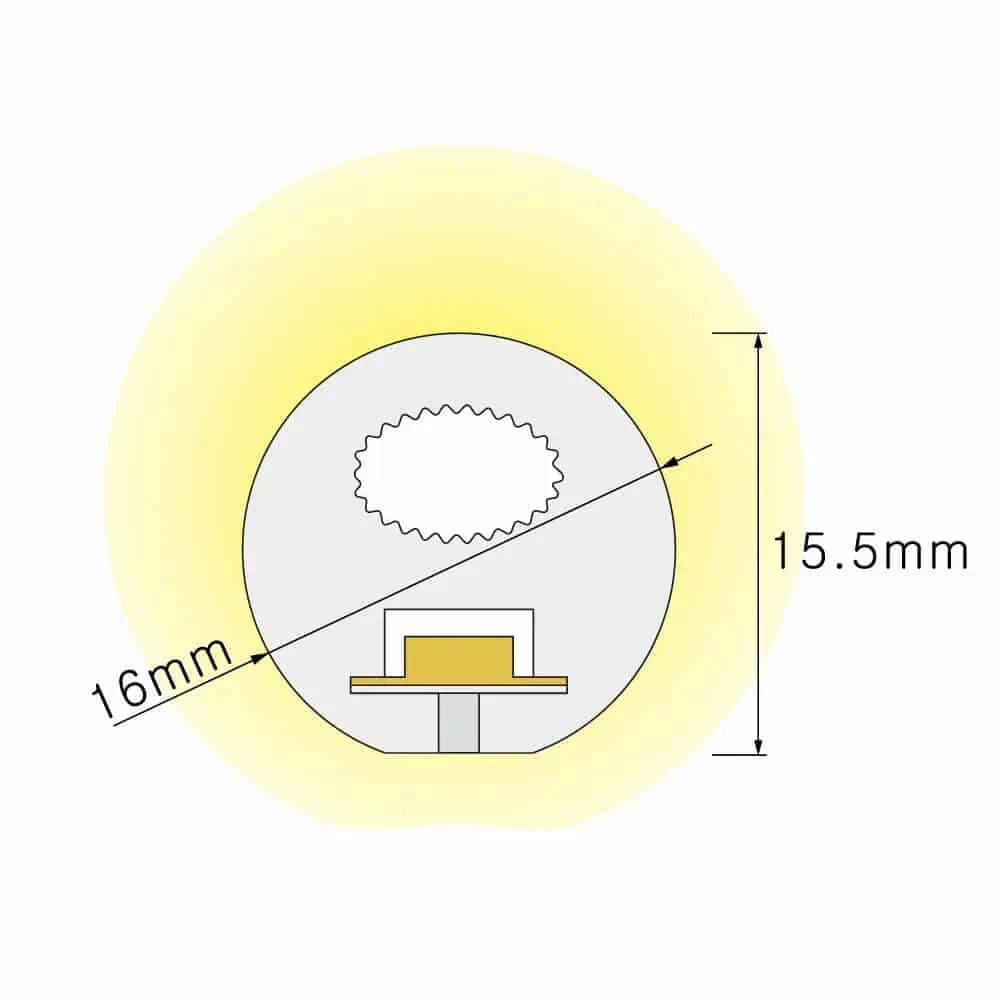

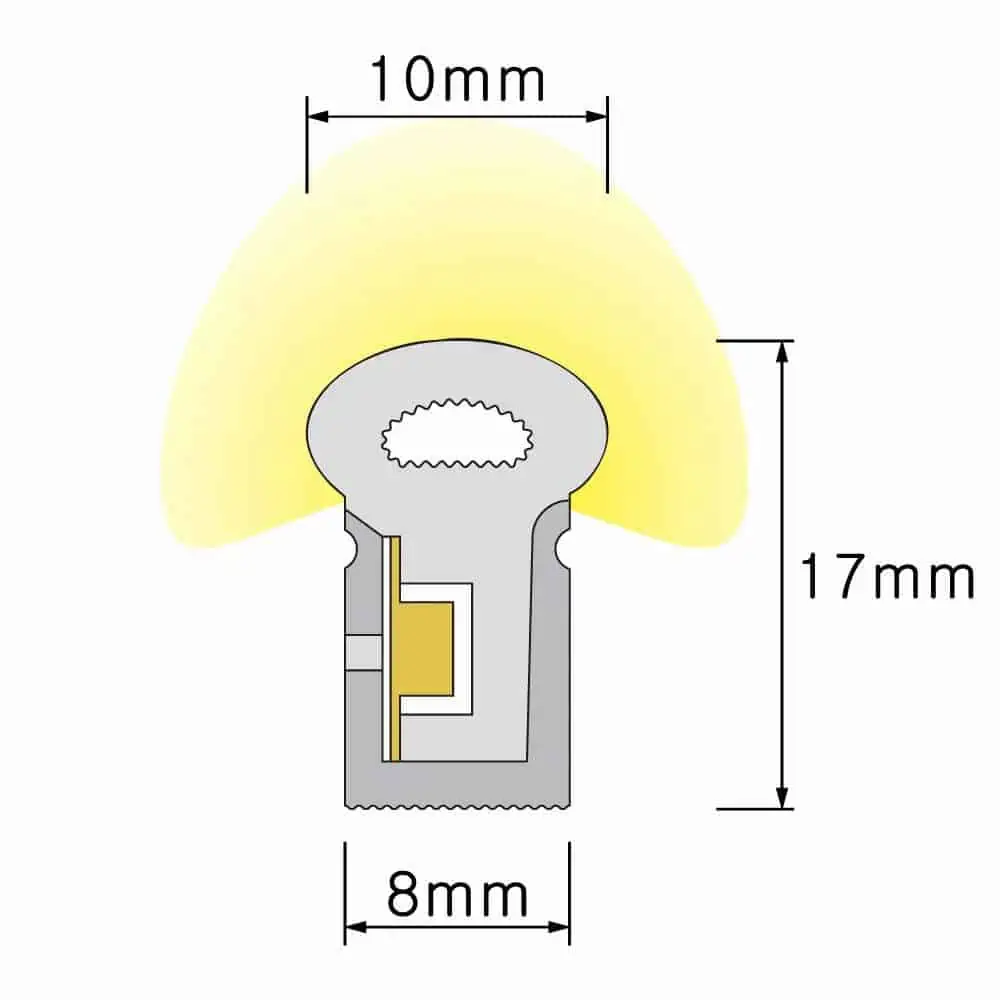

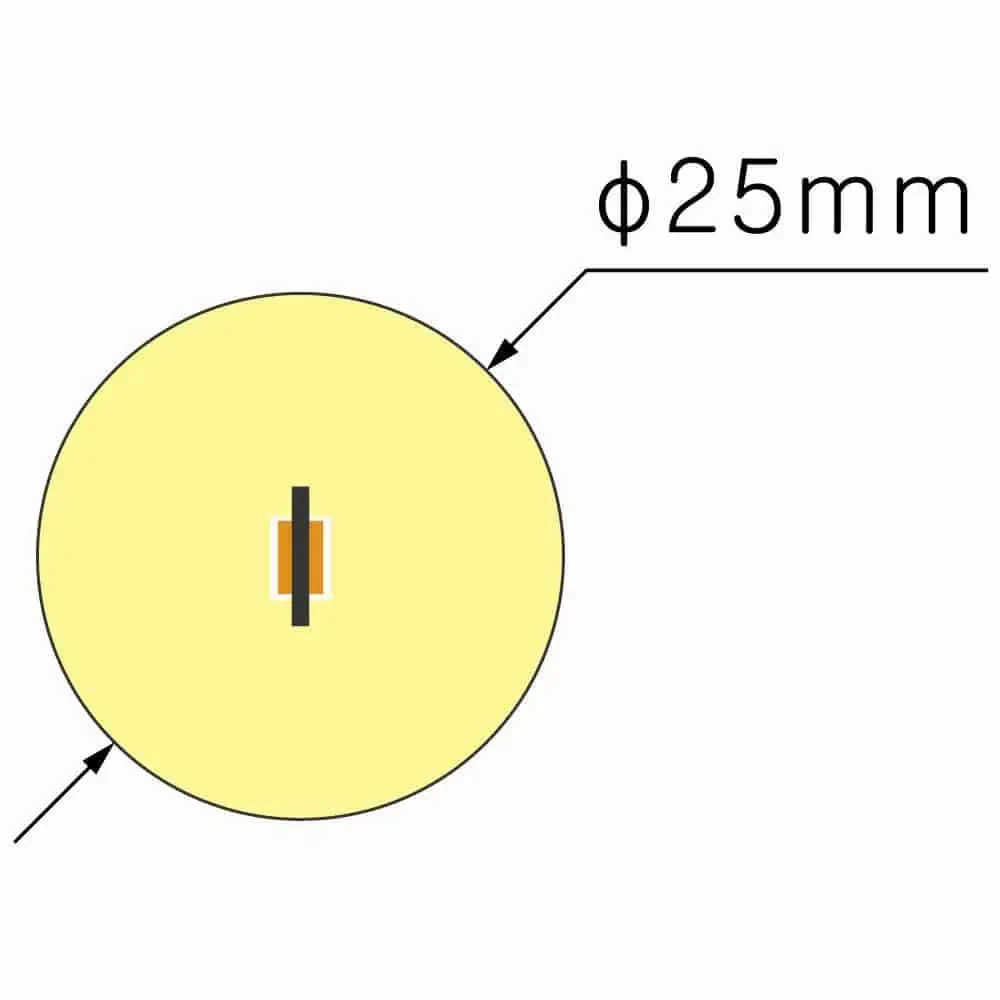

360° round series adopt innovative technology, 360° light emission, no dark area. Flexible material, match with different application solution to meet any molding needs. Can be applied in straight line, circular, curved, and other special shape. It is the best partner for your space design and artistic molding.

Vertical bending Series

Specification Download

IES Download

Horizontal bending Series

Specification Download

IES Download

Custom LED Neon Flex Strip Lights

At LEDYi, custom neon orders are delivered within 7 to 15 days. We cater to all your custom LED neon needs for special events, architectural projects, and any other unique lighting requirements. Our custom options include:

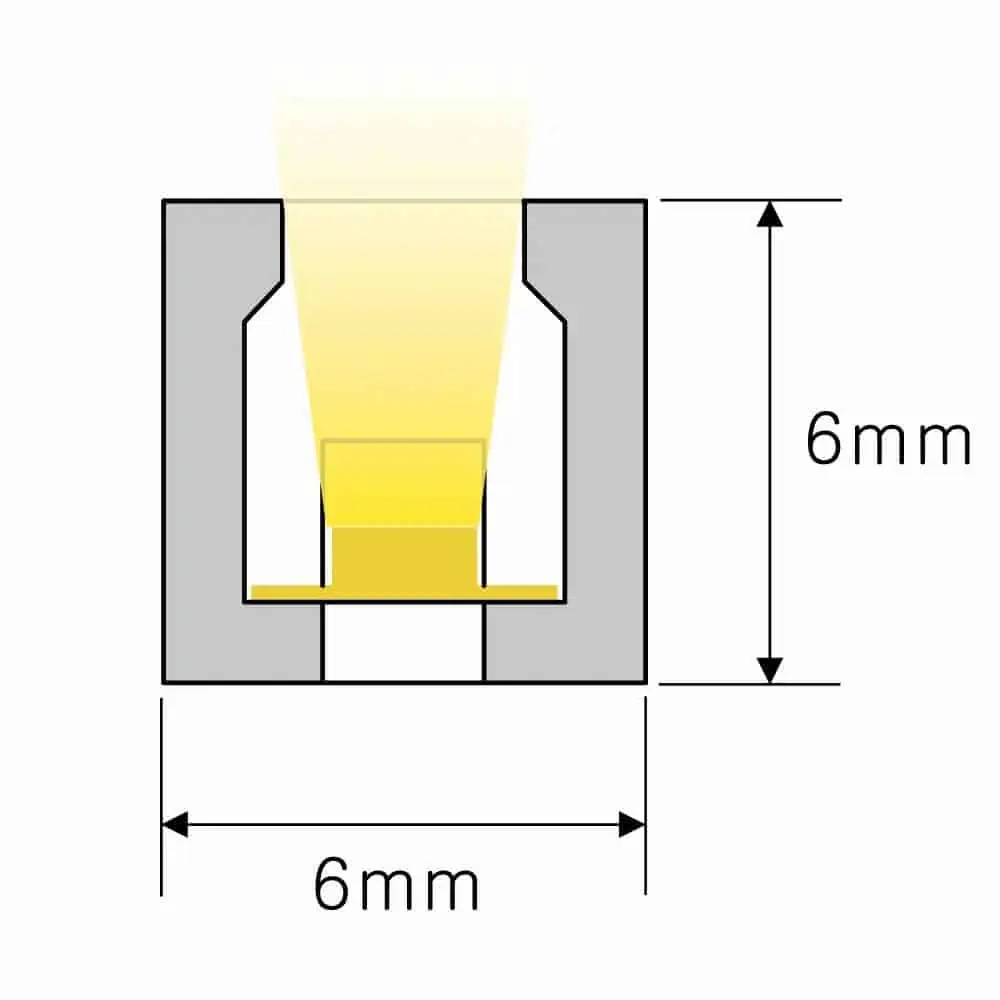

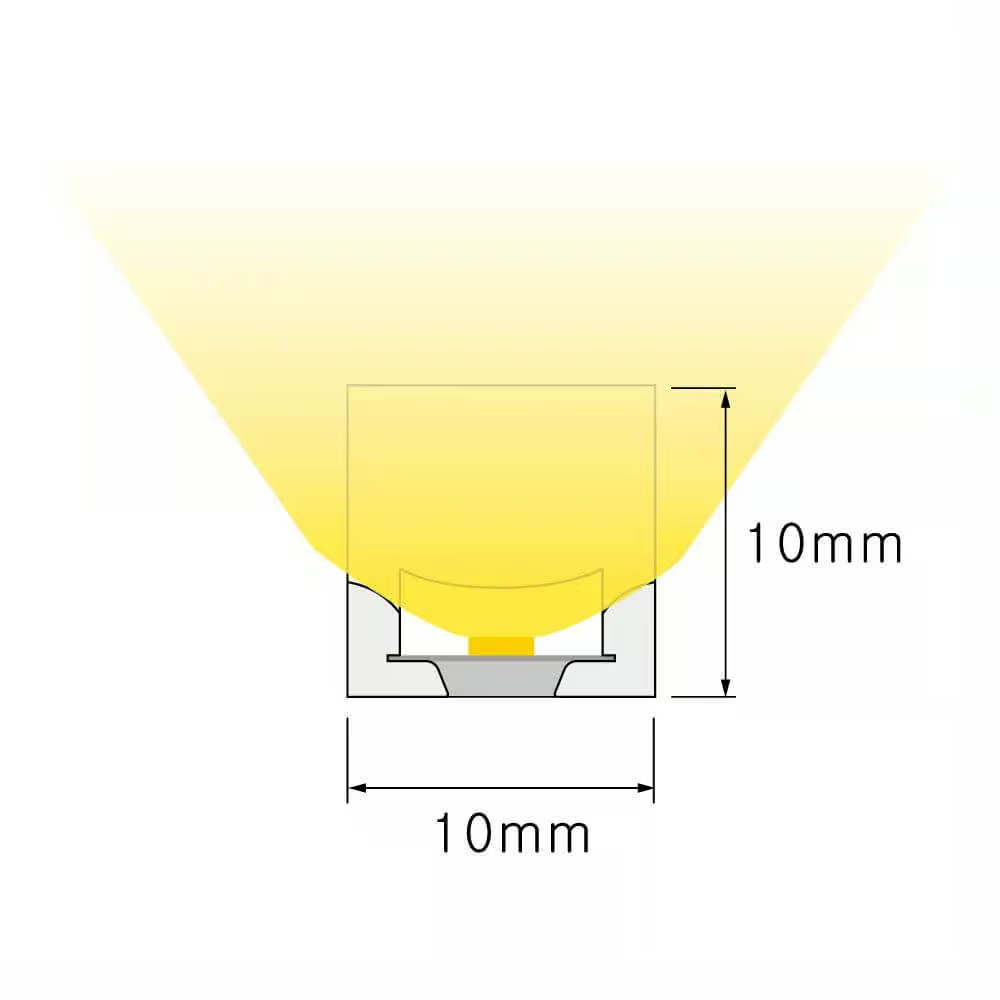

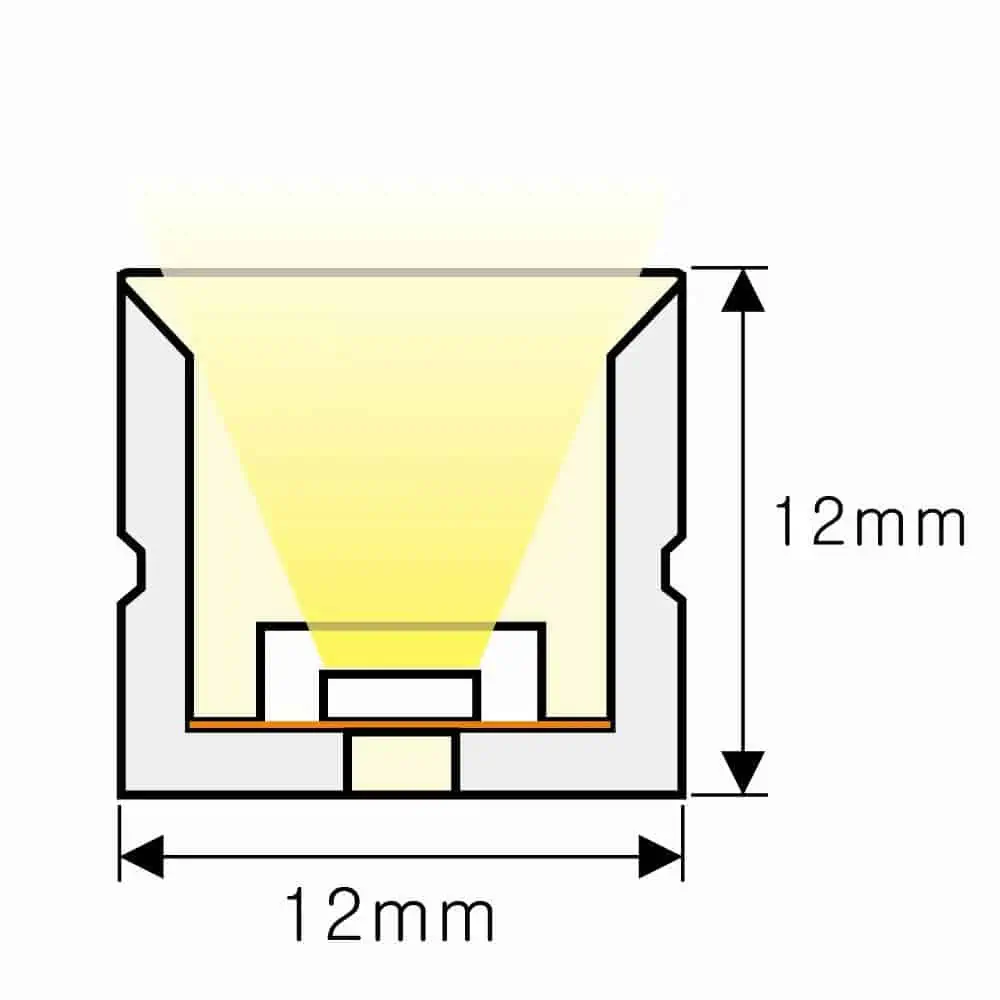

With our custom service, you can choose your neon design’s width, height, and thickness. We believe that every aspect of the neon design is essential, so we offer a myriad of size options to meet the needs of every neon application.

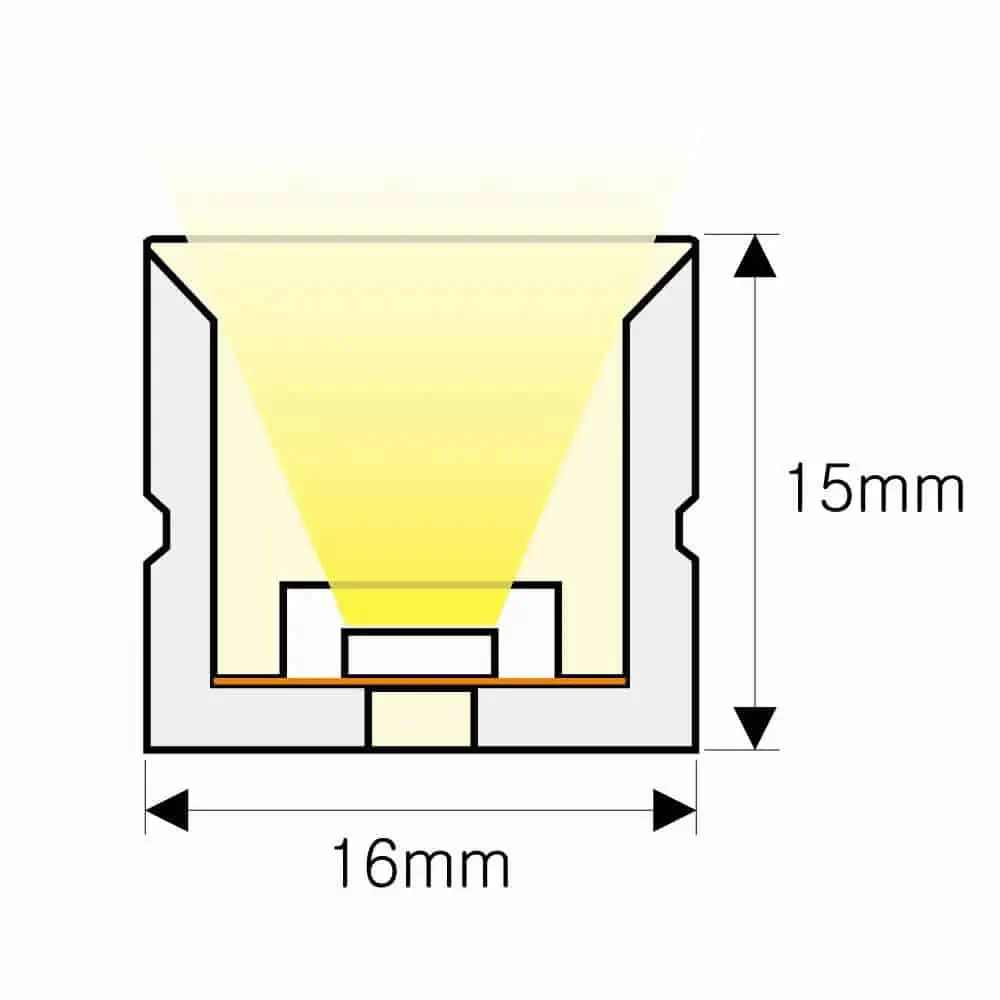

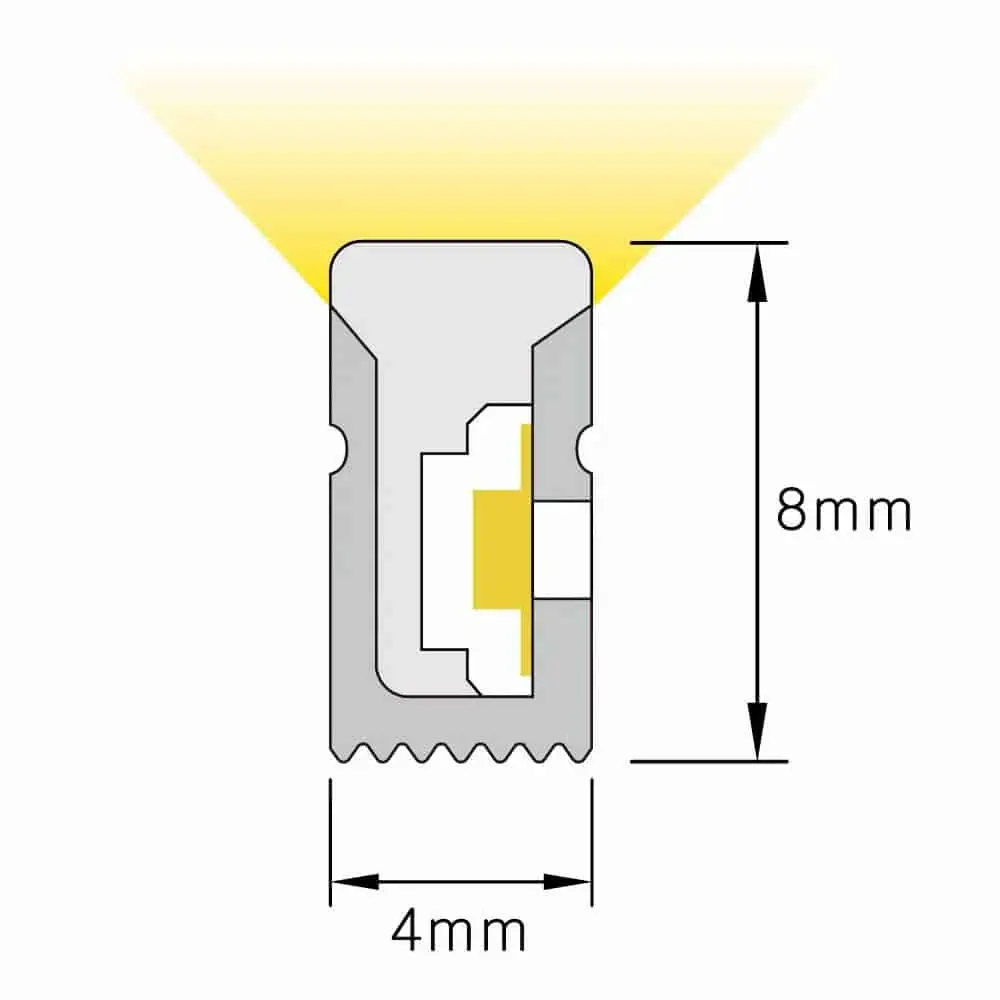

Our products are highly customizable and can be bent into countless shapes. Our usual lineup of neon shapes includes slim neon, flat neon, square neon, tri-view neon, round 360-degree neon, 3D bend neon, and mini neon. These are not the only shapes in our repertoires. We also can shape your neon lights according to your exact specifications.

The higher the IP rating, the more waterproof your LED neon lights will be. The highest wet rating is IP68. We can customize this feature based on your needs.

The standard length of LEDYi LED neon lights is 5 meters. However, we can customize the length of neon by your project’s requirements.

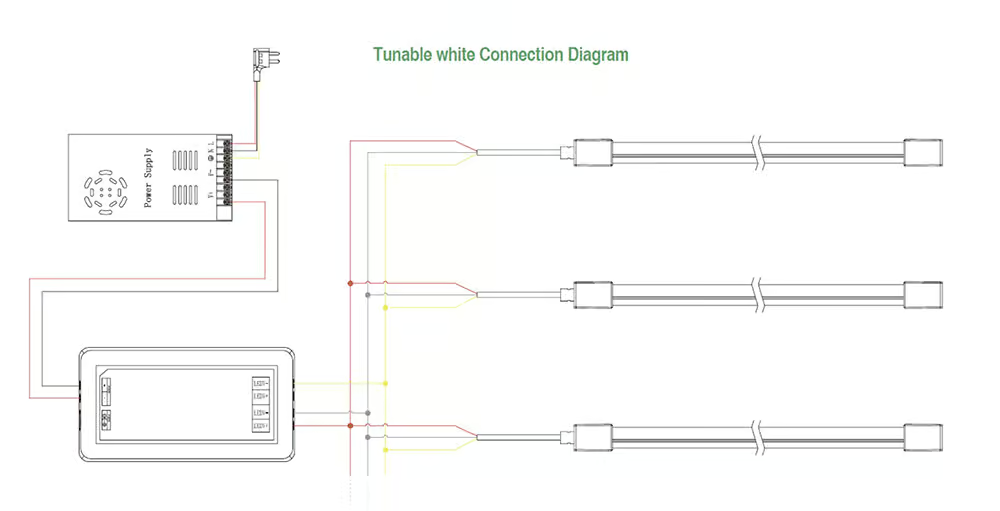

At LEDYi, we can provide monochrome, Tunable White, RGB, RGBW, DMX512 RGB/RGBW addressable LED neon lights.

When it comes to creating a specific ambiance with neon lights, you will need to be as detailed as possible. Color temperature directly affects the feel of an environment. You can choose the right color temperature for your neon lights through our light customization service.

The CRI or Color Rendering Index is necessary for creating vivid and accurate light effects. Our products can support CRI features that reach up to Ra95.

We can also provide customized service of voltage according to the project’s needs. For example, 5V, 12V, 13V, 24V, 36V, 48V, etc.

Adjusting the brightness of LED neon lights helps set different kinds of ambiance. We can customize the power consumption to be suitable for accent lighting, lighting under-cabinets, or ceilings, among others.

Outlets and bend options are essential aspects of neon light design. A poorly positioned outlet or an inefficient bend can affect the product’s overall effectiveness. To avoid any design errors, we give our clients overall freedom in choosing their outlet and bend designs.

We take the needs and comfort of our customers very seriously, including the packaging of our products. We want to ensure that our customers get their purchases in the best condition possible. We offer 5m, 10m, 50m, 100m of rope lights. Each one is stored in an anti-static bag or box to ensure the product’s safety.

Experimental Test

All of our LED Neon Flex Rope Lights are not mass-produced until they have gone through multiple rigorous testing steps in our laboratory equipment. This ensures high performance and stability and the product’s long life.

Dust Proof Test

Waterproof Test

Solar Radiation Test

Needle Flame Test

Bending Test

Torsional Test

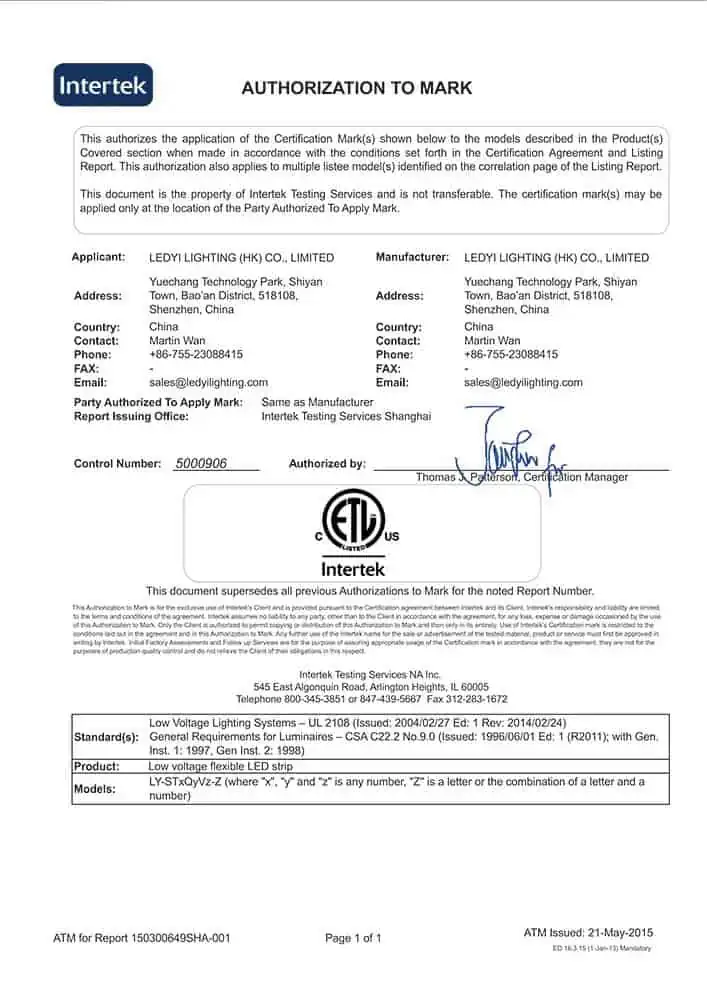

Certification

We always strive to provide our customers with the best possible customer experience when working with us. In addition to our excellent customer service, we want our customers to be confident that their LED neon lights are safe and of the highest quality. To ensure the best performance, all our LED Neon Flex Tube Lights, Neon Flex Sign, lampu Neon Flex, Slim Neon Flex RGB, RGBW have passed CE, RoHS certificates.

Why Wholesale Neon Flex in LEDYi?

We know that more LED Neon Flex manufacturers have emerged with the rise of the decorative lighting industry. That’s why we aim to differentiate ourselves by providing our customers with the best LED neon products on the market.

Convenient Customization

We have a professional R&D team of 15 member. If you have specific requirements for your project, we are always here to help you. We manufacture and customize molds that require particular dimensions and accessories.

Flexible MOQ

We offer flexible minimum order quantities to meet the real needs of your project. Our minimum order quantities start at a relatively low 10m, giving you the highest flexibility in the testing market.

Full Specification

We offer a wide range of LED Neon Flex categories, allowing you to save more time and effort when looking for different products. We will always do our best to meet all your needs.

Fast Delivery

We have more than 200 experienced workers and use automated production lines to ensure faster delivery.

Competitive Price

When you choose LEDYi as your LED Neon Flex supplier and buy in bulk, you will benefit from our competitive wholesale prices.

Aftersale Services

Our team will ensure that you receive your order of led neon flex strip lights and assist in troubleshooting any challenges you may have.

FAQ

Yes, you can. But you need to cut LED lampu Neon Flex rope light on the cut mark. You can see the cut markings “scissors or black line” through the LED neon transparent window. If you cut the LED Neon Flex anywhere other than the cut mark, you will damage the PCB, which will cause the segment of LED Neon Flex to fail.

No, you can’t. You must cut LED Neon Flex on the cut mark. You can see the cut markings “scissors or black line” through the LED neon tube transparent window. If you cut the LED Neon sign Flex anywhere other than the cut mark, you will damage the PCB, which will cause the segment of american lighting LED Neon Flex to fail.

Yes, you can. But, you must cut smart RGB RGBW LED Neon Flexible on the cut mark. You can see the cut markings “scissors or black line” through the neon transparent window.

Yes, LED Neon Flex is IP67 or IP68 waterproof.

Step 1: Cut the LED Neon Flex.

Step 2: Attach solderless connectors to LED Neon Flex

Step 3: Joint the LED Neon Flex with the solderless connectors

Step 4: Light up to test

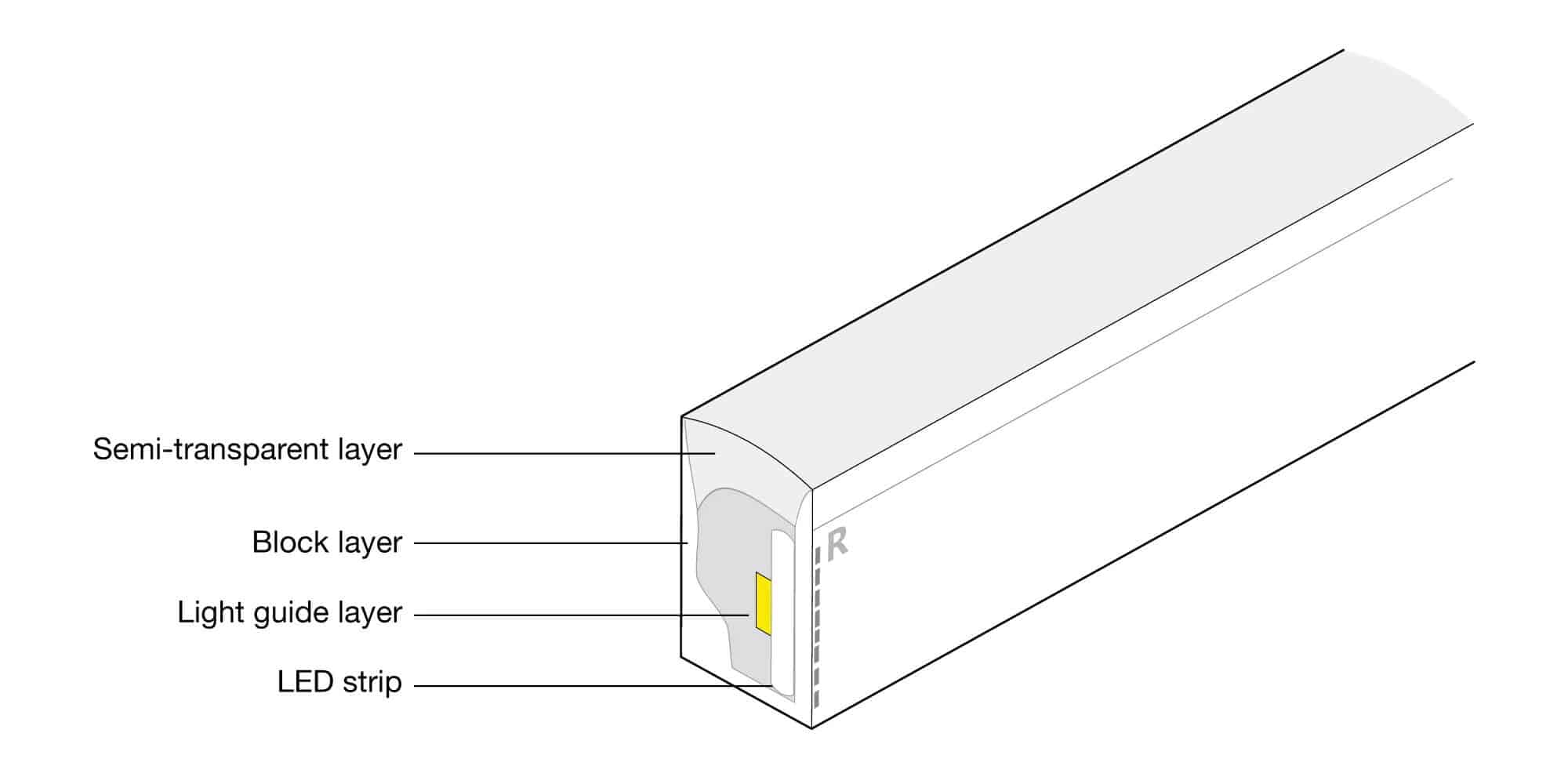

The LED neon light uses LED strips as the light source inside, diffuses the light through the silicone shell, and finally achieves the uniform light without light spots.

Generally, the lifetime of LED neon is between 30,000 hours and 5,000 hours, which ultimately depends on the quality of the light source LED and the heat dissipation effect of the LED neon tube.

Yes. LED neon lights do not contain harmful chemicals such as heavy metals, use less electricity, are not easy to break, have low operating voltage, are safe, and have a longer lifespan.

Traditional Neon lights are brightly emitting electrified glass tubes or bulbs filled with rare neon gas or other rare gases and are a type of cold cathode gas discharge lamp. A neon tube is a sealed glass tube with electrodes at both ends, filled with low-pressure gas. A voltage of several thousand volts is applied to the electrodes, ionizing the gas in the tube, causing it to emit light. The color of the light depends on the gas in the tube. Neon is a transliteration of neon light, a rare gas that emits a popular orange-red light. But other colors are produced using other gases, such as hydrogen (red), helium (pink), carbon dioxide (white), mercury vapor (blue), etc.

1. The working voltage is low because of the LED light source. The power consumption is small and energy-saving. Even in the 24Vdc, it can work well, and its power consumption generally does not exceed 15W per meter.

2. High brightness. The light source is made of ultra-high brightness SMD LEDs, with a density of 120 LEDs per meter, ensuring high brightness and an overall uniform luminous effect.

3. Durable and long life. The light source is made of LEDs, which can last up to 50,000 hours. The flexible silicone/PVC/PU gel is also used, so there is no problem breaking like traditional glass neon light.

4. Flexible, the LED neon flex light can be bent to a minimum diameter of 5CM and sheared.

5. Safe. Unlike traditional glass neon lights, which require a high voltage of up to 15,000V for regular operation, the LED neon flex light operates at 12V or 24V and is safe to use as it will not break and has low heat dissipation.

6. Simple and easy to transport and install. Because the light source is LED and the casing is PVC/Silicone/PU, it will not break during transportation. You only need to fix the mounting clips first or mounting channels, then press the LED flexible neon into mounting clips or mounting channels.

1. Traditional neon lights are expensive, complex, and inconvenient when using glass tubes, high voltage electricity, and inert gas. LED neon flex lights using LED technology and a new structure, with a PVC, silicone, or PU housing wrapped around the LED light source, using unique optical design technology and a special housing design to increase the intensity and uniformity of the light. The LED neon flex is easy to manufacture and very efficient.

2. LED neon flex lights are brighter than traditional neon lights.

3. LED neon flex lights have a longer life span and are more durable. With LED as the light source and PVC/Silicone/PU housing, the life span of LED neon flex is up to 30,000 hours.

4. LED neon flex lights are more energy-efficient, with a minimum power of less than 5W per meter than traditional glass neon lights, generally more than 20W per meter.

5. Traditional neon lights use a transformer to raise the voltage from 220V/100V to 15000V to excite the inert gas in the glass tube. One set of glass tube can only emit one color of light. If multiple colors are required, multiple sets of glass tubes are needed. And the traditional neon shape needs to be designed in advance, and the shape cannot be changed after the factory has produced it. LED neon flex lights can be bent and cut at the site, and there are many different colors to choose from white, tunable white, RGB, RGBW, DMX512 Pixel, etc.

6. LED neon flex lights is safer, as it uses low voltages: 12V, 24V, shockproof, low heat dissipation, and safe to use.

7. Conventional neon lights can only work at normal room temperature, and the voltage must be raised during use, which is also more expensive and has a short service life. The LED neon flex light uses LED as the light source, a cold light source with low heat dissipation and low power consumption. It is also shockproof and heat resistant.

8. LED neon flex lights are more friendly to the environment. While traditional neon lights are polluted with heavy metals, LED neon flex lights do not contain heavy metals or other harmful substances.

Step 1: Measure the length

Step 2: Find the cut position on the LED Neon Flex

Step 3: Cut the led LED Neon Flex to size

Step 4: Attach connectors to LED Neon

Step 5: Connect the power plug to LED Neon

Step 6: Use screws to fix the mounting clip or mounting channel to the place you need to install

Step 7: Press the LED neon light into the mounting clip or mounting channel

Step 8: Light up the LED Neon to test

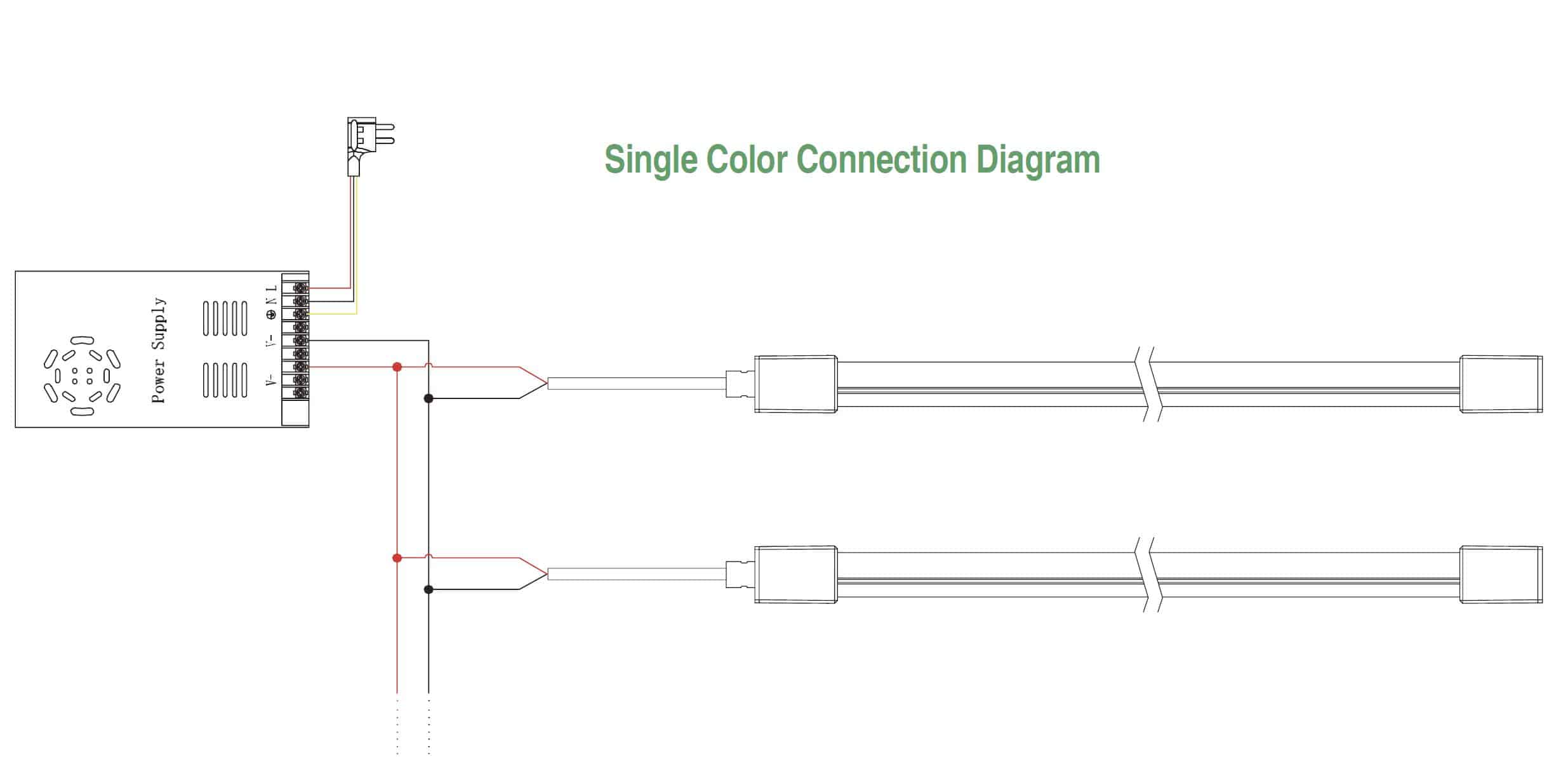

Step 1: Check the working voltage of LED Neon Flex

Step 2: Find a compatible power supply and controllers if need

Step 3: Install the LED Neon Flex on the place your desired

Step 4: Install the power supply and controllers

Step 5: Connect the LED Neon Flex to power supply or controllers

Step 6: Light it up

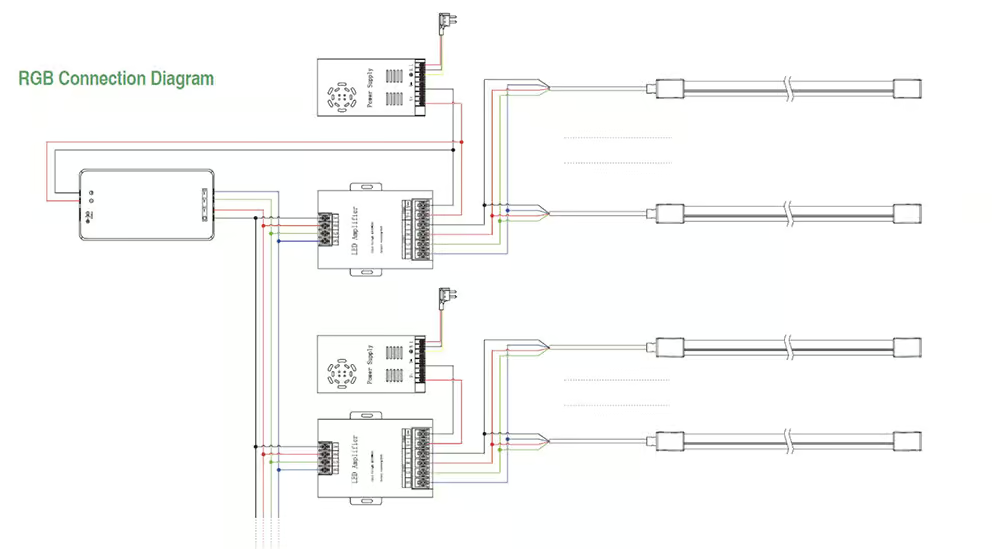

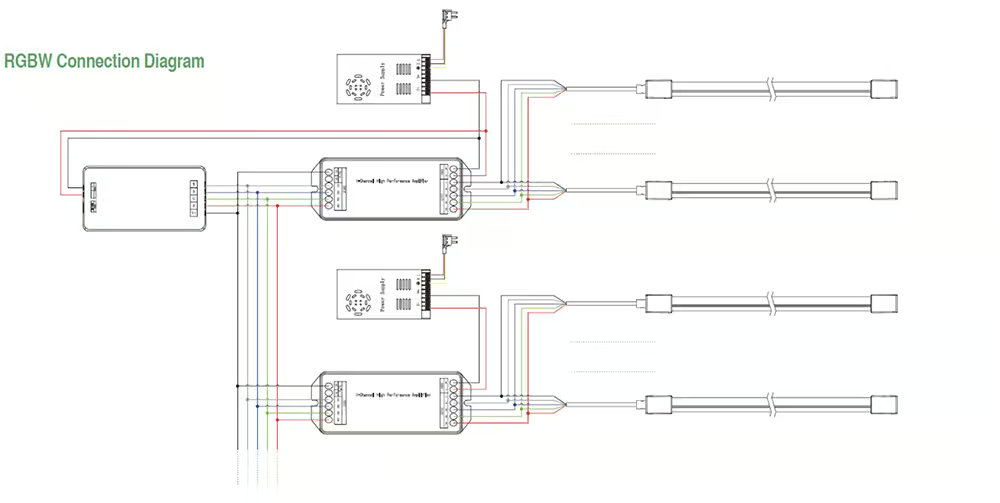

Please check the wiring diagram below:

![]()

Yes, we can.

LED Neon Signs

The lifespan of LED neon signs can be as long as 100,000 hours. While they consume low amounts of power, they still provide high light output. Additionally, they require very little maintenance. On the downside, their angles of illumination can be limited and the initial cost can be high.

LED Neon Flex

LED neon flex lighting is environmentally friendly and very resilient. It can withstand impact and elements of weather without getting damaged. Their installation process is easy and there is hardly any maintenance involved. You may experience a challenge of low brightness with LED neon flex lights compared to alternative lights.

LED Neon Tube Light

LED neon tube lights have vertical designs that provide 360° illumination. They can be suspended or mounted on various surfaces and are available in a variety of colors. On installation, they are plug and play lighting fixtures. Unfortunately, their length is not adjustable unless your neon tube suppliers offer customization.

LED Neon Lamps

LED neon lamps require low power and can serve you for a lengthy lifespan. Some modern designs are portable and can be used as power backups or for camping. The illumination from these lamps is soft and not harsh on the eyes. They, however, can be limited to unidirectional lighting.