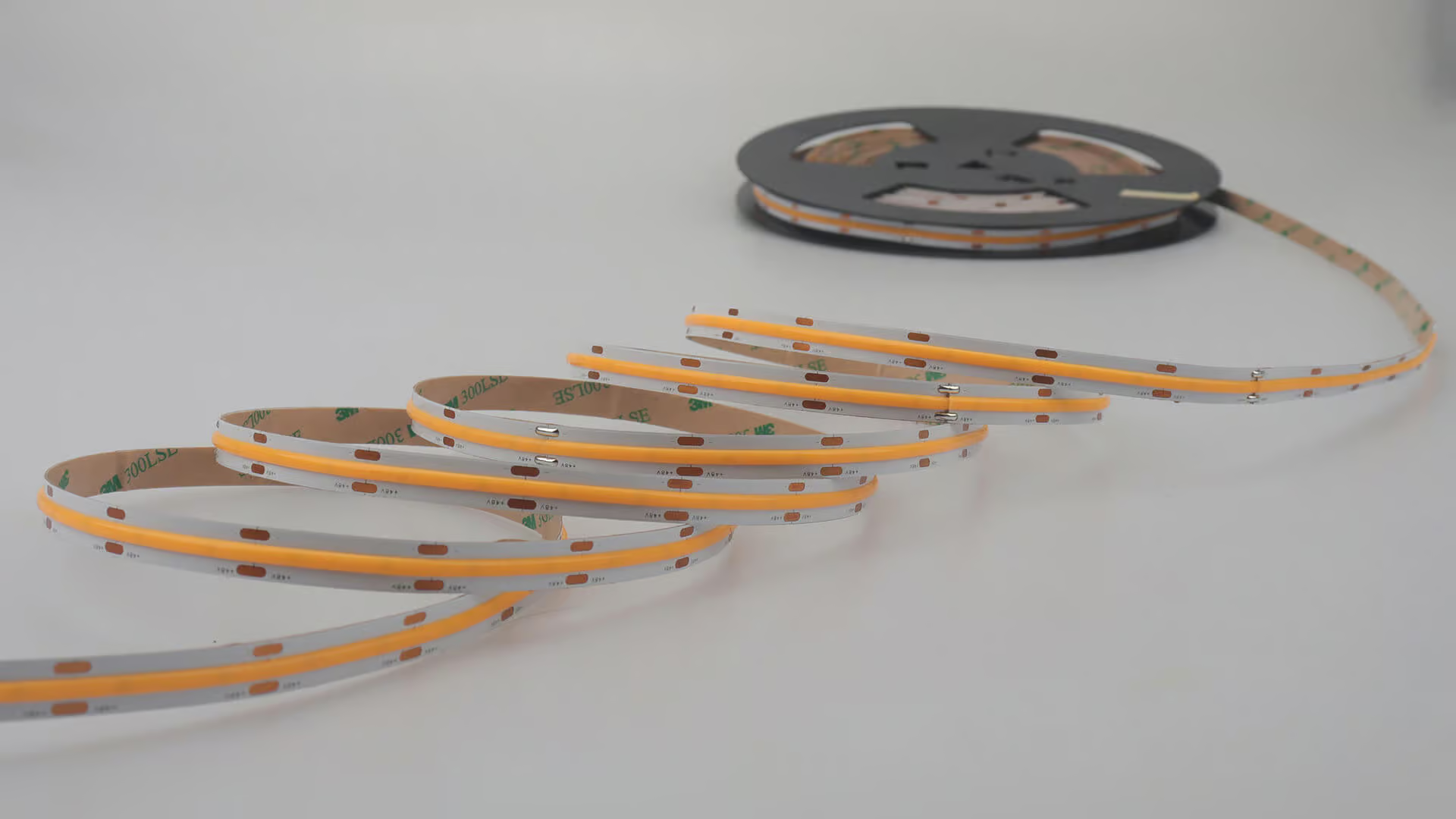

COB LED Strip

- Fully automated production, fast delivery time.

- LM80 compatible LEDs, lifetime up to 50,000 hours.

- 5 years warranty.

- Professional R&D team, support customization, ODM, OEM.

- Free samples are provided.

- Quick response to any of your inquiries.

COB LED Strip Supplier & Manufacturer

LEDYi Lighting is a professional COB LED Strip manufactures in China. We offer customized solutions, OEM, ODM service. Wholesalers, distributors, dealers, traders, agents are welcome to purchase in bulk with us.

All our COB LED Tape Lights are CE, RoHS and LM80 certificated, ensuring high performance and long lifetime.

If you have customized need for bulk robus Red, RGB, RGBW COB LED Strip Lights, LEDYi can offer custom COB LED Strip Light with custom color, size, long, CRI, and various accessories.

What is COB?

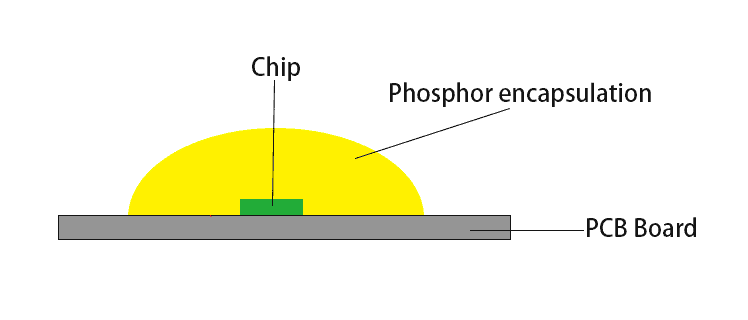

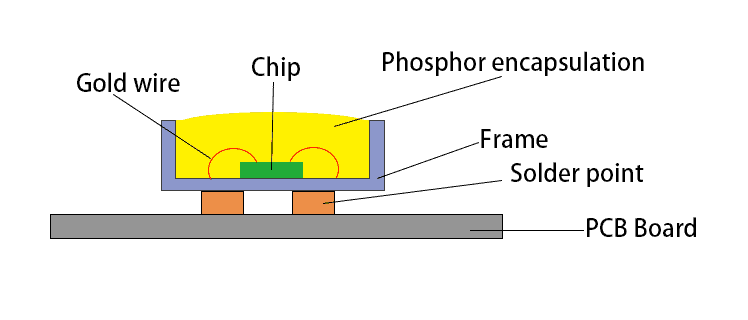

COB stands for Chip on Board in the LED field, which basically means that the LED chip is packaged directly on the circuit board (PCB). “Chip on Board” LEDs for flexible cob led strip lights are sometimes referred to as flip-chips.

Flip chip LEDs are basically a bare-bones approach to LED construction. Take a look at an ordinary SMD (Surface Mount Device) LED. It has a Lamp bead holder that package the LED chip and then covers it with a phosphor coating. The ‘flip chip’ that makes up the COB LED strip removes everything from its design, except for the LED chip, yellow phosphor cover layer, and connection pads.

What is COB LED Strip?

COB means Chips on Board, which means that the chips are directly encapsulated on the flexible PCB board, and the COB led strip is a strip of chips encapsulated on a flexible board. The chips are mostly flip-chips, which are linearly fixed on the PCB board, and then a layer of encapsulation glue mixed with phosphor is directly dropped on the surface of the chip. The light emitted from the chip is refracted, reflected, and interacts with the phosphor, and the glue emits different colors and color temperatures of light evenly.

So, COB LED strip light is also called continuous led strip light or dotless led strip lights.

Features & Benefits of COB LED Strip

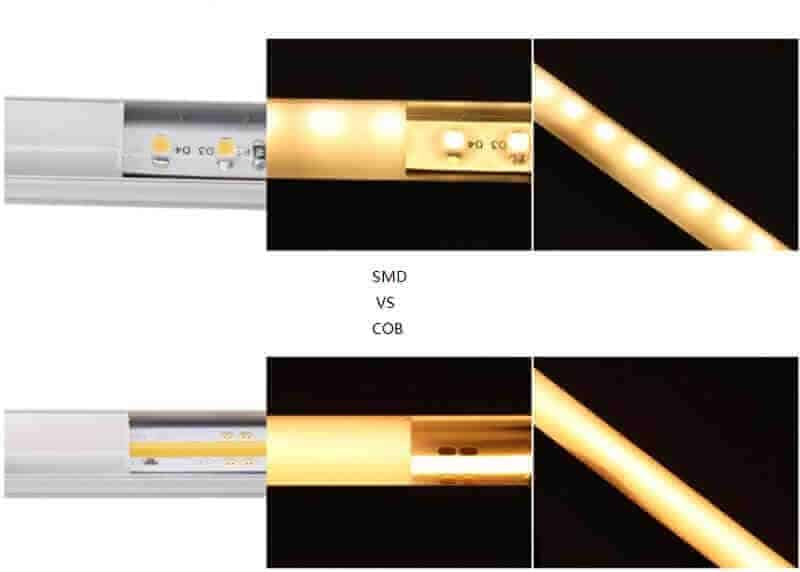

One of the biggest complaints about traditional LED strips is the lighting dot throughout the strip. A lighting dot is a bright area through the strip where you can see where the light is coming from. Light is more soft and attractive when it looks like a smooth light source rather than a lighting dot mess.

With 5050 SMD flex strips, the larger diodes are squeezed close enough so that the light is spread out and consistent across the illuminated surface at a distance. But if the light is too close to the surface or the strip itself is visible, the hot spot is an obstacle that the human eye cannot ignore.

With a 480 chip/M COB strip, it is pretty challenging to pick out any hot spots on the COB flex strip. This strip shines a soft, uniform light from end to end. Even light with no lighting dot is more attractive to the human eye and gives off a steady light even in the narrow places. The only natural way to see the lighting dot is to look at the back of the strip, where it is easier to see the individually placed flip-chip LEDs. You can only see the individual led if you dim strip down to about 5% brightness. This makes COB flex strips ideal for applications where

- The led strip itself cannot be hidden from view.

- The surface being illuminated is within 2 feet of the light bar.

- Reflective surfaces like granite/glass are all around.

- Those applications where you want an excellent neon effect.

COB led strip lights are much more flexible than other flexible strips because of the small size of the diodes and the uniform weight distribution. These diodes are so small and closely spaced that no point of the strip is the same. This uniformity makes it easy to set up the strips without planning around a 5050 SMD LED sticking out where you don’t need it. This extra flexibility will make it easier for them to fit into tight areas and turn corners in your application.

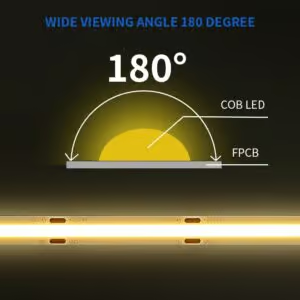

The traditional SMD light strip luminous angle is 120 degrees, while the COB led tape light luminous angle is 180 degrees.

- COB strip is the chip directly attached to the FPCB, does not come with gold wire. Traditional SMD LED strip, very many problems are caused by the gold wire inside the LED beads. Because the gold wire is too small, it is straightforward to be broken, leading to the chip not being illuminated.

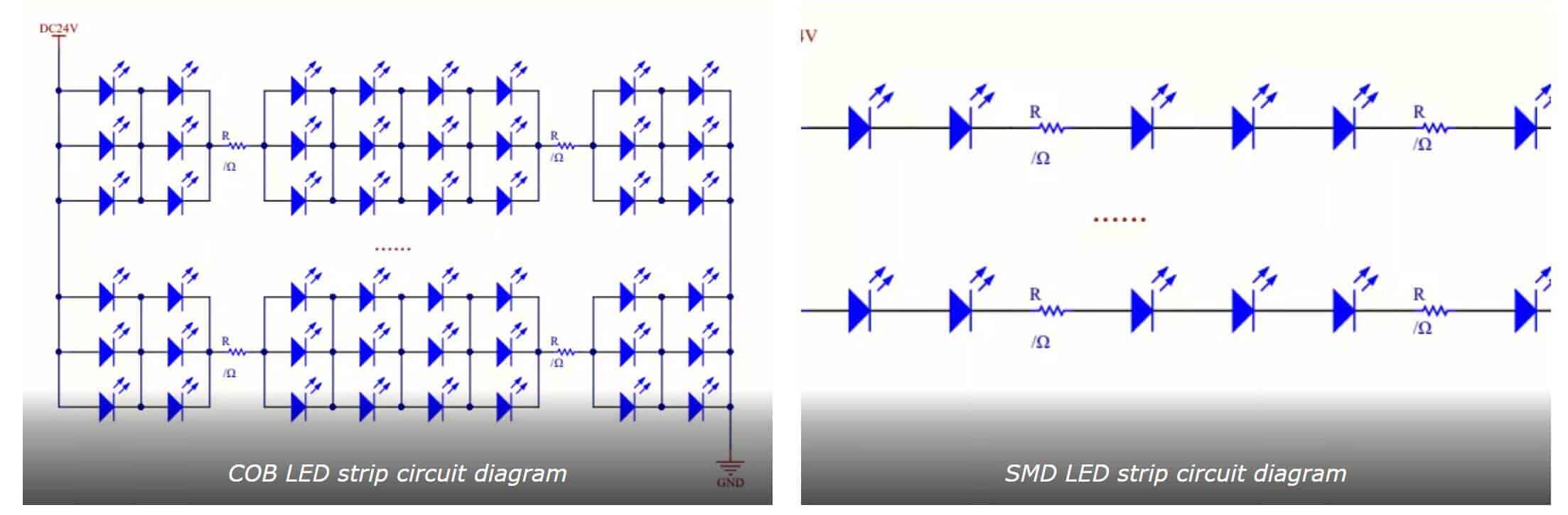

- The circuit design of the COB strip uses three chips, first in parallel, as a group, then each group, and then in series to form one step. Even if a group of two chips inside the bad, this one-step strip can continue to light. And COB a meter of chips how big 480, even if 1-2 chips do not light, will not produce dark areas, will not affect the use. While the traditional SMD strip, a CUT, as long as there are lousy lamp beads, this one cut will not light, so there will be obvious to see a section of the dark area.

The COB chip is directly fixed on the PCB board, the heat of the chip can be quickly transferred to the PCB board. Therefore, the heat dissipation rate of the COB led strip is faster than that of the SMD led strip, and subsequently, the light decay of the COB led strip is smaller, and the life span is longer.

Applications of COB LED strips

LEDYi is a professional COB LED Strip lights factory and exporter. The COB flexible LED strip that we manufacture is highly versatile and can be used in various different industries.

- Architectural lighting

- Furniture & wine cabinet lighting

- Holtel renovation lighting

- KTV & KTV bar lighting

- Parking lighting

- Shopping mall lighting

How To Produce COB LED Strip?

Step 1:Expanding Chips

Step 2:Die bonding

Step 3:Resistors onto FPCB

Step 4:Reflow-High temperature over 65 degrees for finished PCB with chips and resistors

Step 5:Fluorescent Powder glue mixing

Step 6:Drop the mixing glue on the surface of chips and resistors by auto glue machine

Step 7:Put glued cob led strip into the oven

Step 8:QC-testing the cob led strip after cooling

Step 9:Soldering the PCB into 5 meters per reel or the length as customer request

Step 10:Aging test, QC test, packing, then shipping

Cutting & Soldering COB LED Strip Lights

COB led strip can be cut just like smd led strip lights. Please only cut along the cut marks marked on the strip every 50mm (24) / 25mm (12V). This allows you to cut the strip to a custom size or add gaps to your application. The cut strips can be used again and are best connected by soldering, but if this is often not an option, our COB strip connectors also are available as an option.

Wholesale COB LED Strip By Series

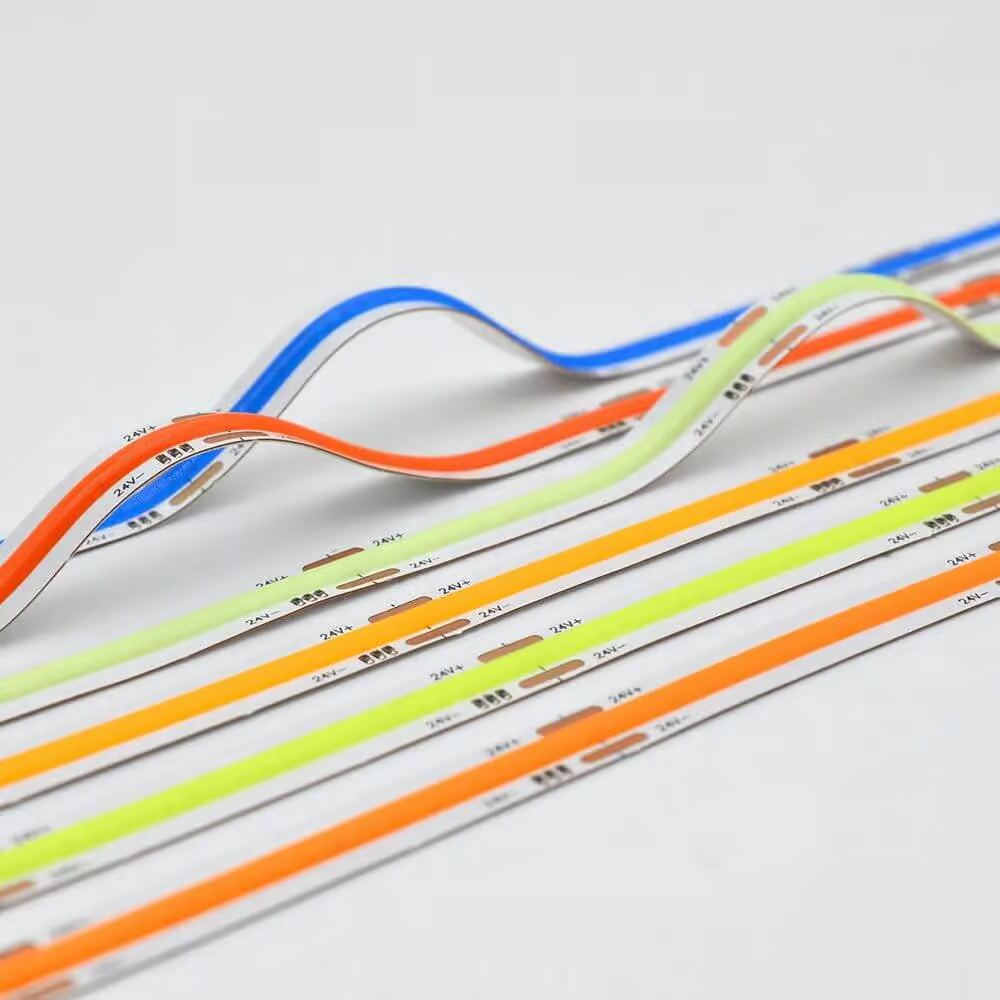

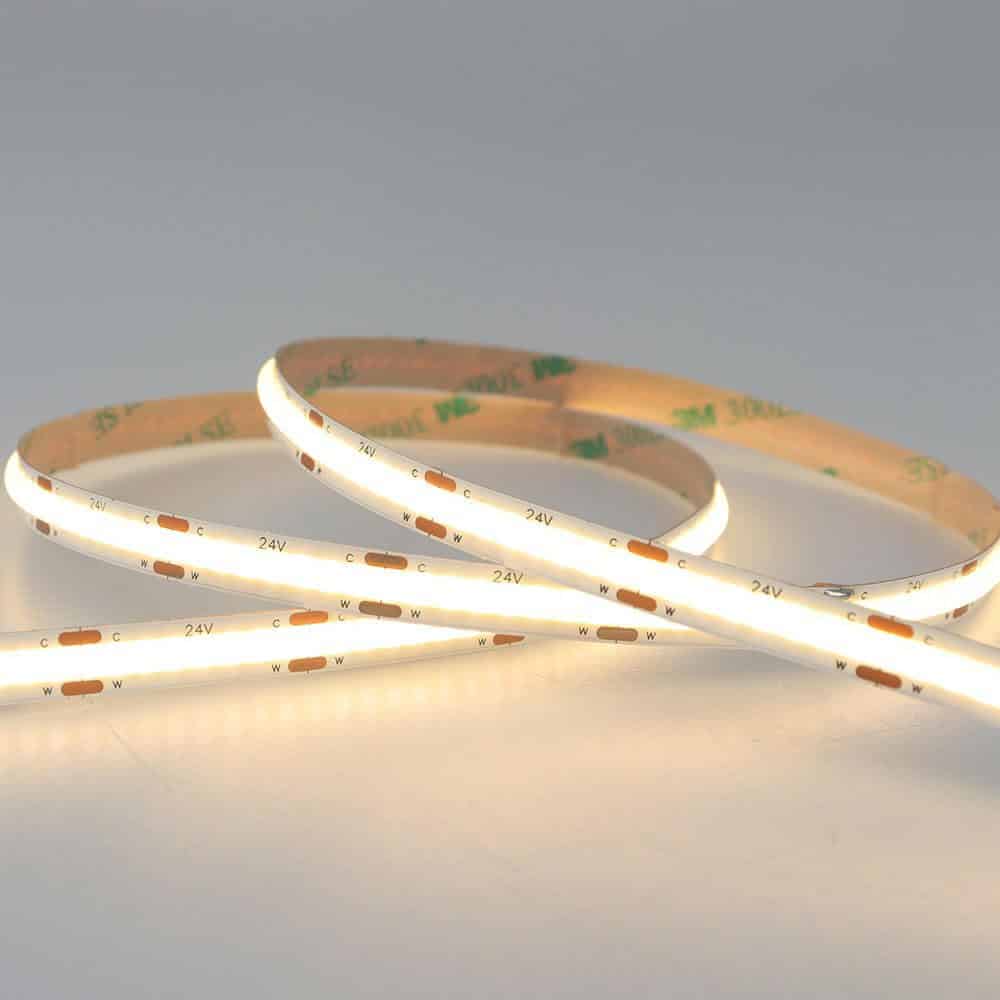

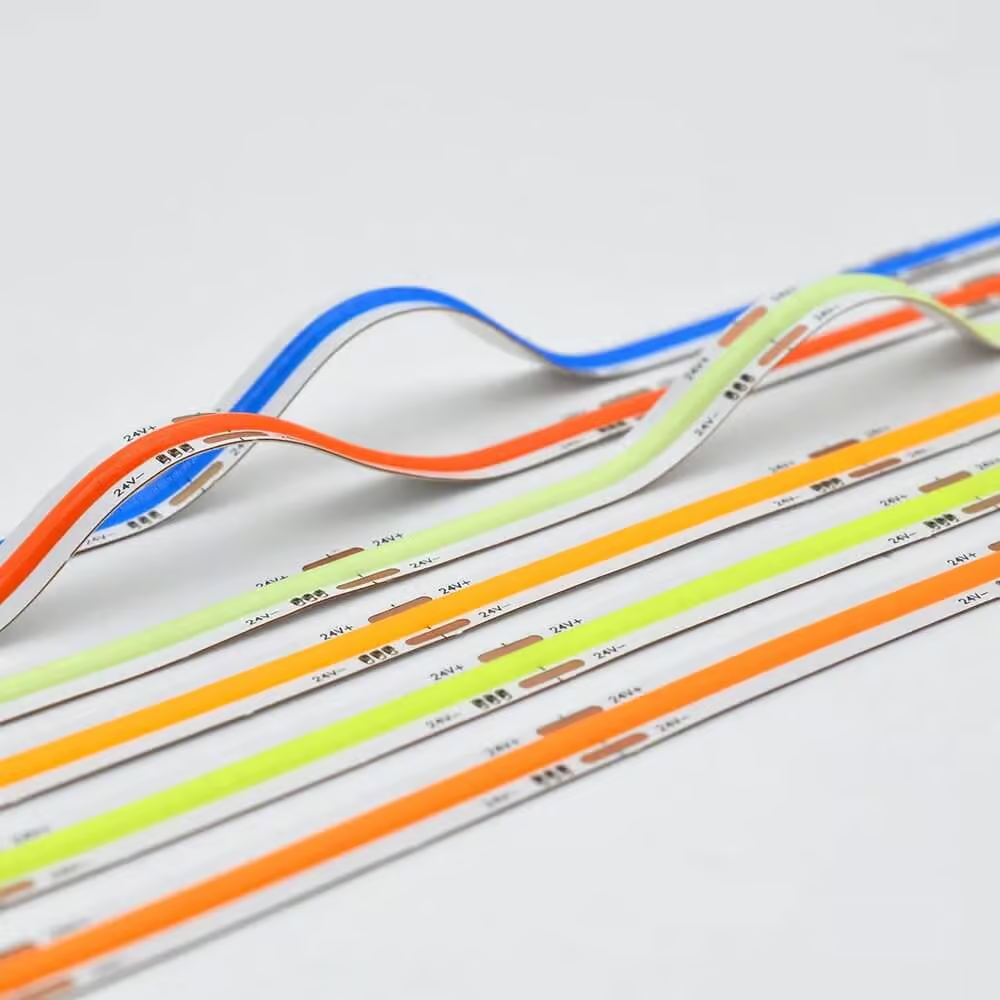

Mono COB dotless led strip

The Mono COB led strip light includes white, red, green, blue, yellow, orange, Tiffany blue, Mars green, pink and more. The color temperature of white light is 2700K, 3000K, 4000K, and 6500K, and the CRI is greater than 90.

The width of PCB is 4mm, 8mm, and 10mm optional.

The density of chips is 480 chips per meter.

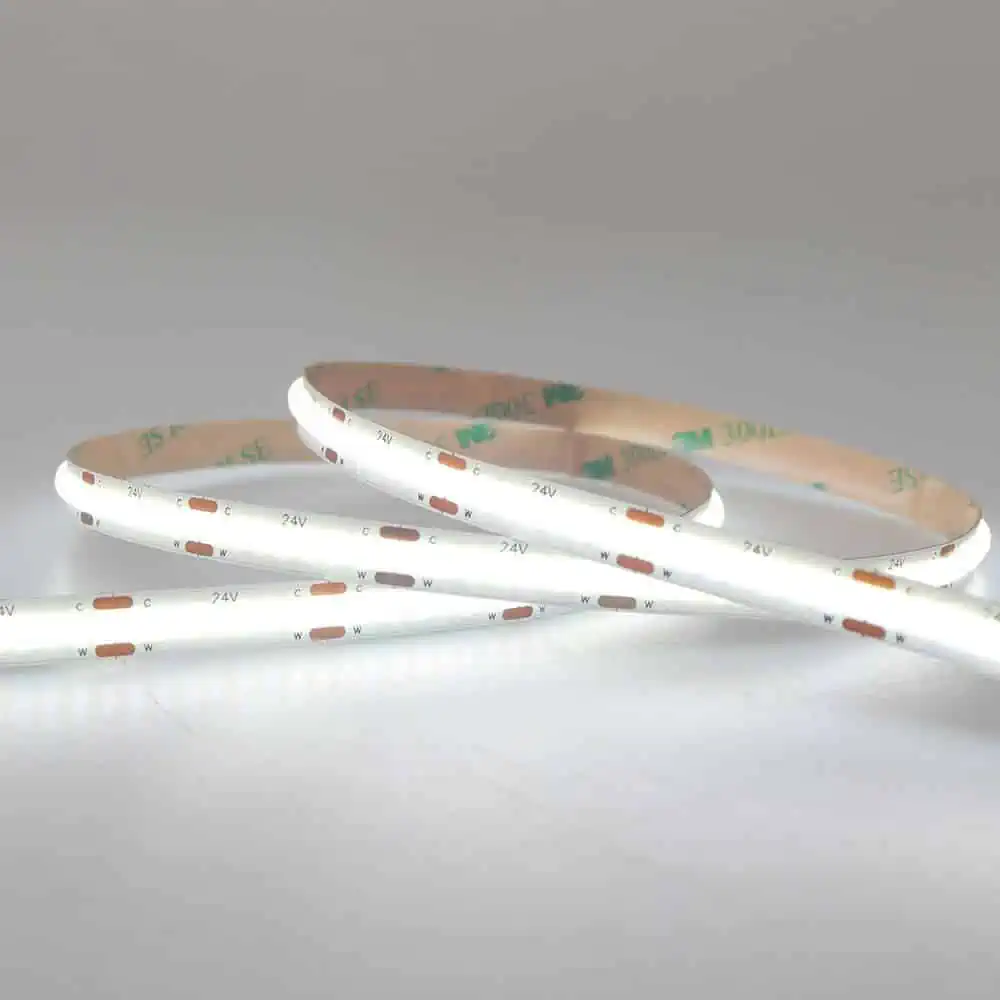

Tunable white COB dotless led strip

Tunable white COB led strip or CCT adjustable COB led strip, up to 576 chips per meter, no light spots. With the tunable white led controller, you can change the color temperature from 2700K to 6500K. Except the regular 3 wire 10mm width PCB tunable white cob led strip, there is also 2 wire 8mm PCB tunable white cob led strip.

RGB COB dotless led strip

RGB COB led strip, high density led chips, up to 1134chips per meter—no lighting dots. With the RGB LED controller, you can change the color of the RGB COB LED strip in various ways.

RGBW COB dotless led strip

RGBW COB led strip, based on RGB COB strip, adds white light. You can get purer white light instead of RGB mixed white light.

48V COB dotless led strip

48V COB LED Strip, 3oz double layer PCB, 10W/m, CRI90, 15 meters long run. Pass LM80, 50,000 hours long lifetime, five years warranty. Using silicone one-piece extrusion waterproof process, waterproof grade IP52, IP65, IP67 optional, and the length can be up to 15 meters in a roll.

Specification download

Product Video

Custom COB LED Strip Lights

With our custom service, you can choose your cob led strip design’s width, height, and thickness. We believe that every aspect of the cob led strip design is essential, so we offer a myriad of size options to meet the needs of every cob led strip application.

Our cob led strip are highly customizable.

We can make the COB strip into strips, circles, triangles, panels, etc. Just tell us what you need, and we will help you to realize it.

We can make COB led strip lights waterproof to IP52(silicone coating), IP65(silicone tube), IP65H(heat shrink tube), IP67(silicone filling), IP67E(silicone extrusion), IP68(PU encased).

We can also meet your other IP-rated customization needs.

The standard length of LEDYi cob led tape lights is 5 meters per reel. However, we can customize the length of cob led tape lights by your project’s requirements.

LEDYi is a professional fabrication company that manufacturing led strip lights and provide oem & odm service. At LEDYi, we can provide monochrome(white, red, green, blue, pink, yellow) cob led strip, Tunable White cob led strip, RGB cob led strip, RGBW cob led strip, addressable cob led strip.

The CRI or Color Rendering Index is necessary for creating vivid and accurate light effects. Our cob led tape lights can support CRI features that reach up to Ra95.

We can also provide customized service of voltage according to the project’s needs. For example, 5V, 12V, 13V, 24V, 36V, 48V cob led strip, etc.

Adjusting the brightness of cob led tape lights helps set different kinds of ambiance. We can customize the power consumption to be suitable for accent lighting, lighting under-cabinets, or ceilings, among others.

LEDYi is a professional custom cob led tape lights maker. We take the needs and comfort of our customers very seriously, including the packaging of our products. We want to ensure that our customers get their purchases in the best condition possible. We offer 5m, 10m, 50m, 100m of cob led tape lights. Each one is stored in an anti-static bag or box to ensure the product’s safety.

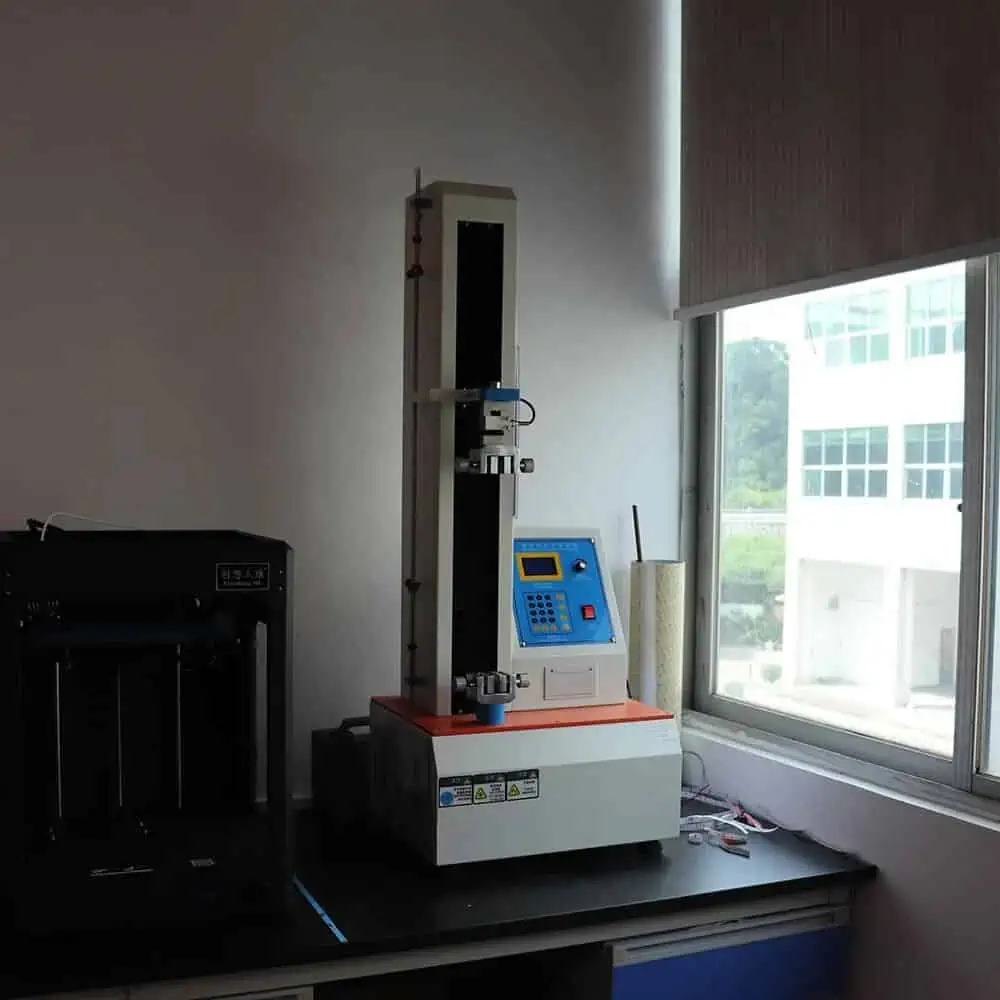

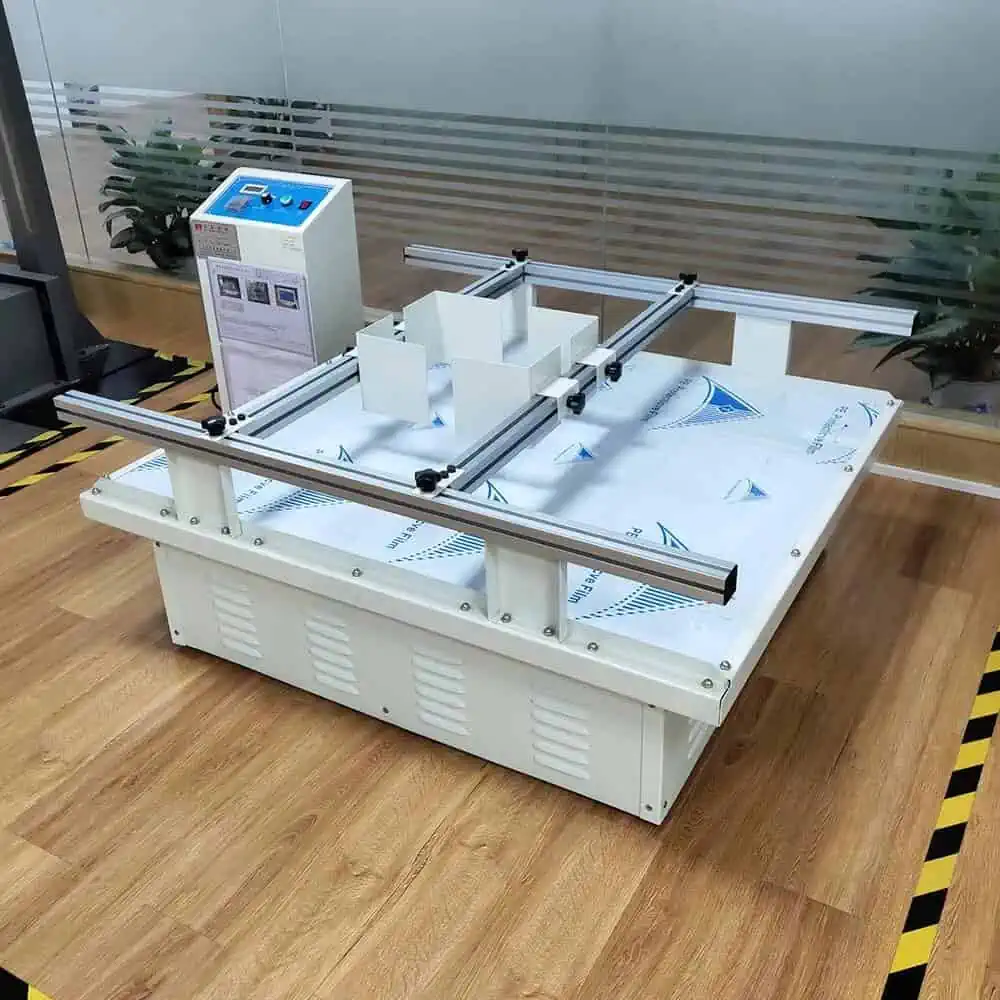

Product Testing

All of our COB LED Strip Lights are not mass-produced until they have gone through multiple rigorous testing steps in our laboratory equipment. This ensures high performance and stability and the product’s long life.

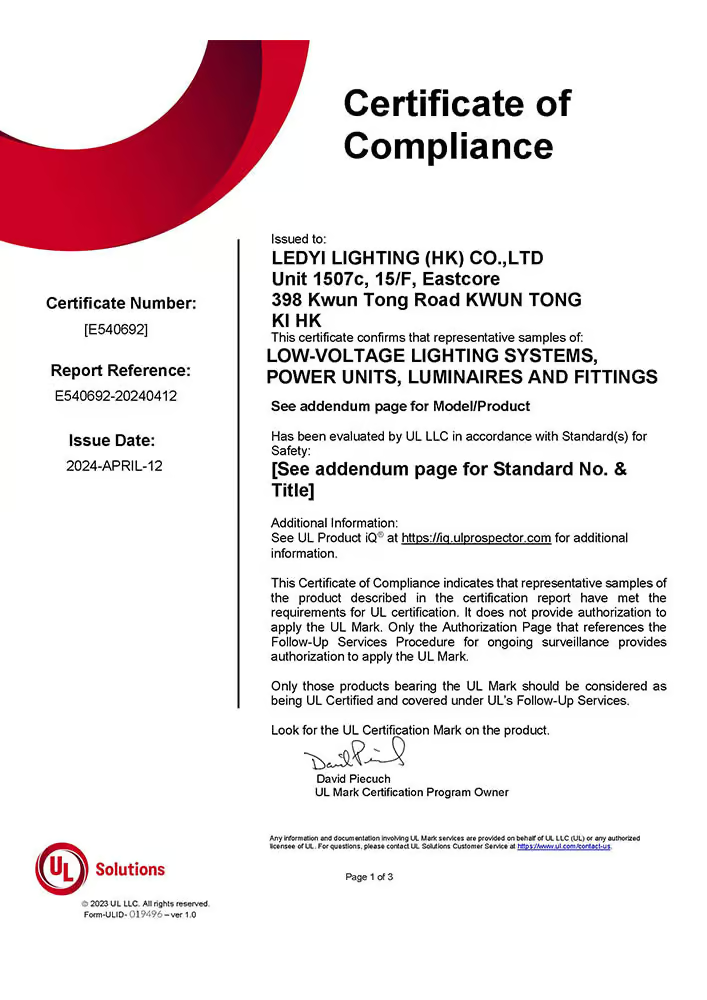

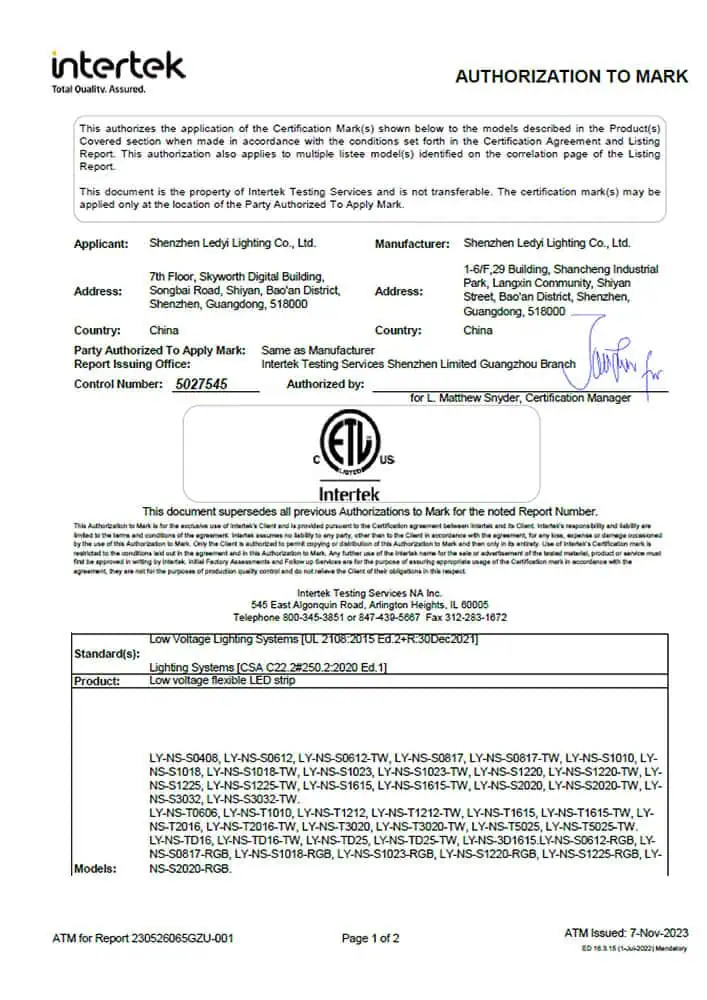

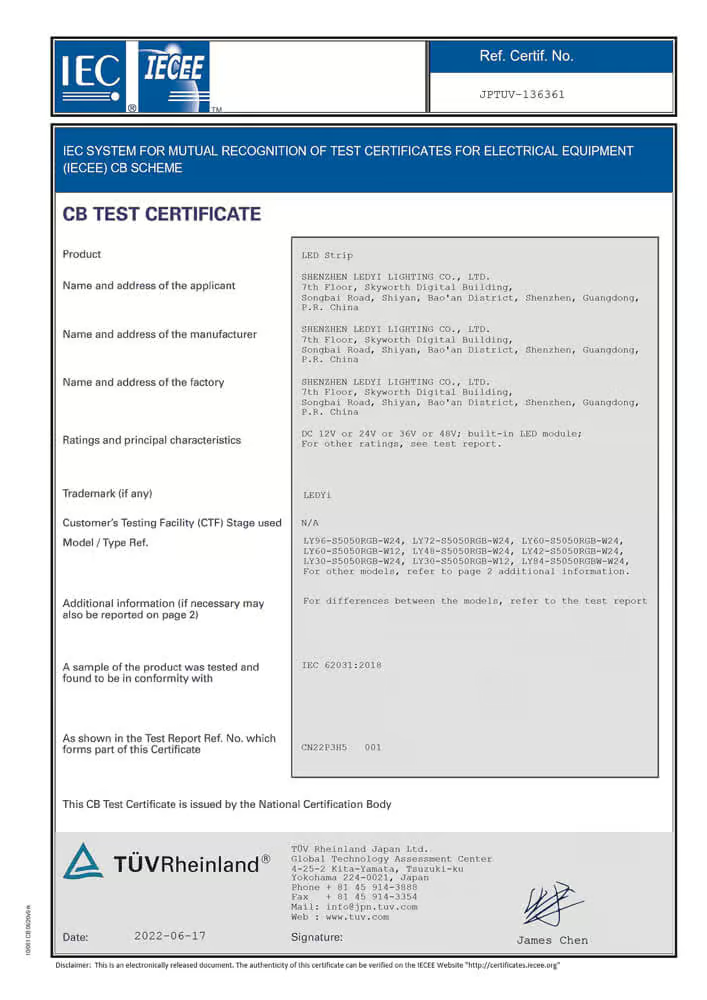

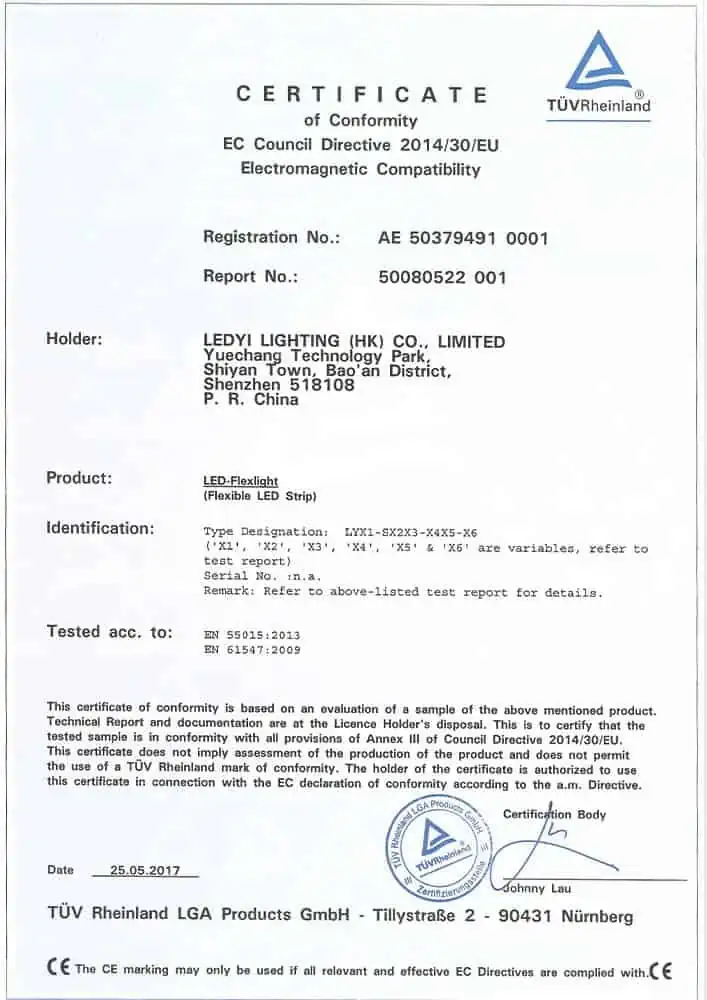

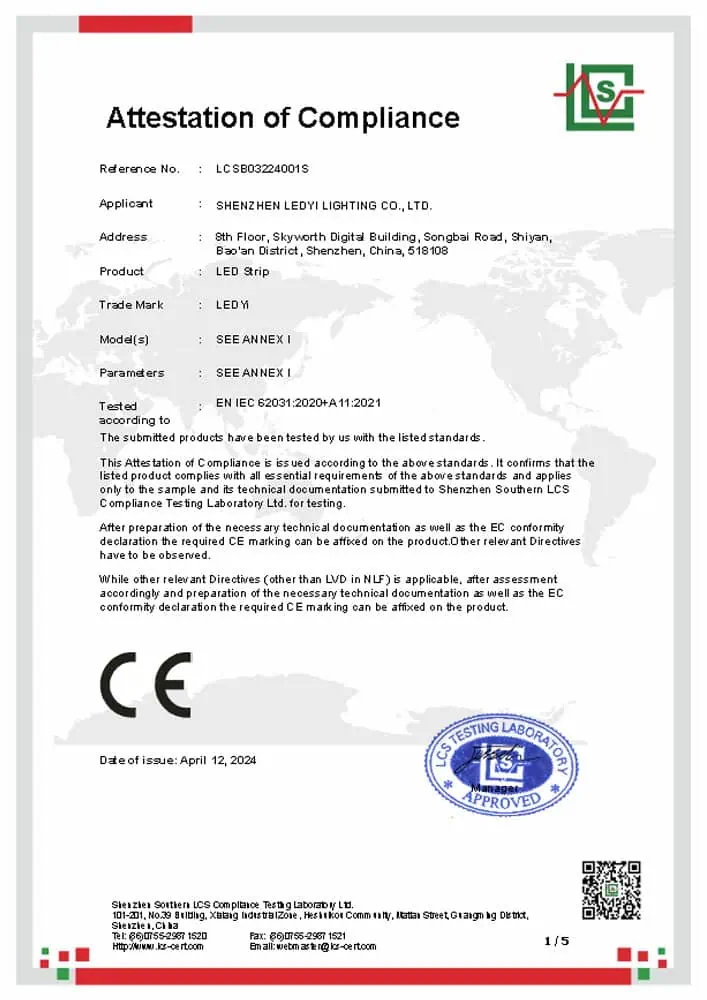

Certification

We always strive to provide our customers with the best possible customer experience when working with us. In addition to our excellent customer service, we want our customers to be confident that their cob led tape lights are safe and of the highest quality. To ensure the best performance, all our cob led tape lights have passed CE, RoHS certificates.

Why Wholesale COB LED Strip In Bulk From LEDYi

LEDYi’s products go through various quality tests to offer high-end products to its users. Here are a few reasons why you should get the COB LED lights from us.

We provide high-quality products that have been tested at every step of its making to ensure the best quality products. All our cob led strip has pass LM80, CE, RoHS test.

Customization

We have a professional R&D team of 15 member. If you have specific requirements for your project, we are always here to help you. We manufacture and customize molds that require particular dimensions and accessories.

Flexible MOQ

We offer flexible minimum order quantities to meet the real needs of your project. Our minimum order quantities start at a relatively low 10m, giving you the highest flexibility in the testing market.

Competitive Price

When you choose LEDYi as your LED Neon Flex supplier and buy in bulk, you will benefit from our competitive wholesale prices.

Fast Delivery

We have more than 200 experienced workers and use automated production lines to ensure faster delivery.

Aftersale Services

Our team will ensure that you receive your order of led neon flex strip lights and assist in troubleshooting any challenges you may have.

FAQ

Yes, we can provide free samples for your testing. But it would be best if you bore the shipping cost.

There is no MOQ for our regular models. If you want to make a new PCB design, MOQ is 1000 meters.

If the raw materials are in stock, the delivery time is 8-10 days. Otherwise, the delivery time is 18-20 days.

We generally use DHL, UPS, FEDEX to ship the goods. The days required for transportation vary according to the destination, but the general is 3-5 days.

In general, 5 meters are packed on a plastic reel and then packed into an anti-static aluminum foil bag.

Yes. In the case of small quantities, we can use our PCB printer to print the LOGO. In the case of large amounts, our PCB supplier will help to print the LOGO in advance.

Yes, all cob led strip lights are dimmable.

Yes, you can cut cob led strips on the cut place, with a Scissors mark and black line.

More than 50000 hours.

The SMD LED light source is a single-patch LED lamp bead with a light-emitting diode directly attached to the surface. COB LED light source packaging technology is a direct chip package on the board, and COB has improved light efficiency, improved glare effect of LED lights, and reduced light loss.

Yes, it will help the COB light strip to dissipate heat better and prolong the life of the COB light strip.