Have you ever worried about the lifespan of these flat, tape-like LED strips? You will be amazed to know how long these flexible fixtures can last!

LED strips can last from 50,000 hours to 100,000 hours! That is, you can use these fixtures over decades. Ratings like L70, L80, or L90 express the lifespan of LED strips. As their life span shortens, they gradually become dimmer. There are several factors like voltage, wattage, temperature, weather, etc. affecting their lifespan. Nevertheless, with proper maintenance, the life expectancy of LED strips can be effectively increased.

With years of experience, I bring you an in-depth analysis of the lifespan of LED strip lights. You will also find some of my professional tips to boost the longevity of these fixtures. So, let’s begin:

Average Lifespan Of LED Strip

LED strips use LED technology, which is highly durable compared to other traditional lighting methods. The average lifespan of LED strips is 50,000 hours. That is, if you turn on these lights for 10 hours every day, they can last for more than 13 years! However, it’s not like after this period the lights will not work at all. They will still work but not with the fullest brightness as they lit during the climb’s lifetime. As the lifespan is over, they start to get dimmed.

How Does The Lifetime Of LED Strip Rated?

In the above section, I told you about the average life expectancy of LED strip lights. But do you know how it is rated? The Illuminating Engineering Society of North America (IES) has listed some documentation to rate the lifespan of LED lights; these are as follows:

a. LM-80

LM stands for Lighting Methodology. LM-80 measures the lumen or light output of LED lights for a while under some fixed conditions. This determines the longevity of the fixture. In LM-80 testing, the LEDs are tested under predetermined temperatures, usually – 25° C, 35° C, and 55° C. The time interval for measuring the light output change is 1000 hours, up to a maximum of 10000 hours.

LM-80 testing is usually performed at a third-party laboratory to ensure objective results, and the results are published in a report format. All reputable manufacturers perform this test for their LED lamps, and reputable LED strip suppliers should all be able to provide LM80 test reports, especially if you are buying in large quantities.

However, the difficulty with LM-80 LED life testing is that it takes a long time. Even if the LED lights are on 24/7, a 10,000-hour test takes about 14 months. This is an eternity for fast-moving industries such as LED lighting. Testing a product for the complete 50,000-hour requirement, in turn, requires nearly six years of continuous testing. For this reason, the TM-21 extrapolation algorithm is proposed.

b. TM-21

Technical Memorandum (TM)-21 is a document that states the projected lifespan of LED lights at a fixed temperature. However, the estimated lifespan here is expressed based on the data of LM-80. The lifespan under TM-21 is usually expressed as L70, L80, L90. Their meanings are as follows:

| Lifespan Rating | Meaning |

| L70 | After the rated lifespan, the LED maintains 70% of its stated lumen rating, and the light loss is 30%. |

| L80 | After the rated lifespan, the LED maintains 80% of its stated lumen rating, and the light loss is 20%. |

| L90 | After the rated lifespan, the LED maintains 90% of its stated lumen rating, and the light loss is 10%. |

This means that if you purchase an L80-rated LED strip with a 50,000-hour lifespan, it will still emit 80% of light after 50,000 hours of usage. However, the intensity of the light will gradually keep decreasing as you use them.

You can however detect the lifetime of the LED strip lights, by following the symbols in the packaging or specifications. For instance, LxByCz (h) describes the lifetime of LEDs.

h = Number of hours after which the group of LED luminaires will still provide

Lx = At least x (%) of initial lumen

By = y (%) of luminaires in the same group have dropped below the specified luminous flux

Cz = z (%) of luminaires in the same group have experienced total LED failure

Example: If you purchase an LED strip with symbols like – L70B10C0.1 (50,000 h); it means-

After 50,000 hours, the group of LED luminaires must still provide at least 70% of the initial luminous flux. Where 10% of the luminaires are permitted to provide less than 70% of the initial luminous flux. And only 0.1% of all luminaires will experience complete LED failure.

How Is L70 Calculated?

Of all three (L70, L80, and L90) TM-21 ratings, the LED lighting industry considers the L70 matrix to be the standard one. However, the calculation of these ratings is dependent on the LM-80 report. The TM-21 extrapolation algorithm considers the performance of the LM80 sample for the first few thousand hours and outputs an estimated lifetime.

TM-21-11 report: Projecting long-term lumen maintenance of LED light source

Please check the full LM80 test report here.LM80 test reports generally give the lifetime of L70. However, sometimes we need to know the lifetime of L80 or L90. Don’t worry, I have prepared an Excel tool for you. This tool can convert L70 lifetime to L80 or L90 lifetime. Please click here to download it.

Factors That Affects The Lifespan OF LED Strip

Usage Patterns and Duty Cycle

The lifecycle of LED strips directly depends on their usage patterns. Turning the lights on for a long time without any break increases the thermal stress of the LED. This decreases its lifespan gradually due to overuse. The life span is also affected as you turn on and off the light too frequently.

The rapid changes in power state wear the internal components like the LED drive, which results in a short lifespan. However, you can turn the scenery by operating the LED strip in a short duty cycle and in a cool environment to extend its life expectancy.

Excessive Voltage

LED strip lights are sensitive to voltage. As you extend the strip lengths, they continuously face voltage drops. As a result, the light keeps dimming as the length runs. However, applying a lower voltage than the required rating doesn’t affect the lifespan, as it doesn’t let the LED glow.

The actual effect is seen when you use a high-voltage power supply with a low-voltage LED strip. Though it may seem the LEDs glow brighter than the expected result, eventually, it overheats the LEDs and reduces their lifespan.

Temperature & Heat Management

Heat management plays a significant role in ensuring the LED strip lasts long. LED strips are usually known for their cool operation. They usually don’t get heated easily. However, due to poor quality LEDs, using a higher power supply or connecting multiple strips to a single power supply can heat up the LED strips. This directly impacts the efficiency and lifespan of the LED strip.

Besides, the quality of the resistor used in the LED strip impacts its lifespan. Low-quality resistors overheat the LEDs and shorten the life of the LED strip or even damage it. Therefore, a reputable brand for resistors should be used that keeps the value of the resistor constant.

Power Supply & Battery Capacity

LED power supplies power most LEDs. A poor-quality power supply fails to maintain voltage consistency. It can’t filter out sudden voltage drops or spikes, which disturbs the LED circuit. This reduces the lifespan of the LED strips. To avoid this, you must use a good-quality power supply with compatible voltage and wattage ratings. Remember, the power of the LED strip should not exceed 80% of the rated maximum capacity of the power supply.

Now, you may wonder how battery capacity affects the lifespan of LED strips. Some LED strips use batteries as a power source. These are popular options for temporary installation or lighting areas where there is no available power outlet. The lifespan of such an LED strip directly depends on its power consumption and battery capacity.

For example- using a low-wattage LED strip with a high-capacity battery will make the LED strip glow for a longer period. But if you use the same battery with a high-wattage LED strip, it will consume more power and will not glow as long as in the previous scenario. Thus, you will need to recharge or replace the battery frequently. That is, in battery-operated LED strips, the lifespan of the fixture depends on its battery capacity.

Quality Of LED Chip

Low-quality LED strips are made of cheap LED chips and drivers. They are not properly binned and don’t go through tests to ensure proper operation. Moreover, these cheap quality LED strips don’t have a sufficient heat management system.

Thus, they overheat, fail to tackle voltage drops, and thus reduce their lifespan. Therefore, to ensure your LED strips last longer, you must purchase them from reliable manufacturers. Also, ensure they have all test reports like LM80 or LM70 and other certifications.

Weather Tolerance Of The Light

What if you use a low-IP-rated LED strip outdoors or in areas that come in close contact with water? It won’t last longer, but why? The IP rating is a protection grade against solid and liquid ingress. A higher IP rating means better protection against dust, moisture, rain, etc. So, a low-rated LED strip isn’t resistant to dust and water.

If you install this fixture in open weather, it will soon die out when coming into contact with extreme weather or rainwater. Therefore, it is crucial to use a suitable IP rating for your fixtures to make them last longer.

However, comparing high- and low-IP-rated LED strips in general, higher-rated ones have shorter lifespans. This is because high IP ratings, like IP65, have outer silicon coatings for waterproofing. This reduces the heat dissipation capacity of the LED strip, which shortens its life.

Therefore, an IP20-rated LED strip that has no waterproofing has a higher lifespan than an IP65 water-resistant fixture. But it doesn’t mean you can expect an IP20 LED strip to last longer when installed outdoors. Weather consideration is a must.

Electrical and Mechanical Stress

The fluctuation in current or voltage stresses out the LED strip which reduces its lifespan. Besides, vibration or physical impact also negatively affects its longevity. This especially occurs when these fixtures are not securely installed. As a result, they consistently face vibration affecting the internal components.

Incorrect Polarity

A wrong polarity doesn’t usually damage the LEDs but impacts the lifespan of the fixture. When you incorrectly connect the LED strips to the power supply for a long time, it causes reversed polarity. Though this doesn’t light the LED but makes them overheated. This can damage the internal circuits and cause short circuits or fire breakouts. Therefore, this will not only lower the lifespan but also create potential life risks.

Using Poor Quality Double-sided Tape

The adhesive backing of the LED strips plays a crucial role in ensuring proper installation and better thermal conductivity. But many suppliers offer no-name or, worse, fake brand-name adhesives. If you use such a low-graded double-sided tape, it won’t stick to the surface accurately. As a result, the LED strip will come off and often face vibrations, which impacts its lifespan. Therefore, always consider 3M brand VHB tape for the best result. All our LEDYi LED strips use original 3M brand VHB tapes to ensure robust installation.

Electrical Currents’ Impact

You might think of maximizing the current as it gives brighter light. But remember there is no such free lunch in physics! Drive currents play a vital role in determining both the brightness and longevity of your LEDs. High drive currents can make your LEDs brighter but at the same time, they generate more heat. So, maximizing the current supply will increase the temperature within each bulb, which can significantly shorten its life expectancy.

Benefits of Long-Lasting LED Strip

Cost Savings

Purchasing a long-lasting LED strip allows you to use the same fixture for a long time. Thus, you don’t need to repair or replace the fixtures frequently with a new one. As per the average lifespan of LED strips, you can use them for over 13 years. This way, it saves you money.

Energy Efficiency and Environmental Impact

LED strip lights are highly energy efficient compared to other traditional lighting. They consume minimal energy to produce the equivalent light of an incandescent or a fluorescent bulb. LED strips use 90% less energy than the incandescent bulbs. Thus, you can save your electricity bills. Besides, due to low power consumption, LED lights also reduce carbon footprints. This decreases greenhouse gas emissions and protects the environment.

Reliability and Consistency

LED strips from reputed manufacturers use high-quality materials and offer certification for 100% reliability. These LED strips generate minimal heat that elongates their life expectancy. Besides, they maintain constant and uniform lighting without causing any flickering issues.

Reduced Maintenance

LED strips with longer lifespans require less maintenance as they have already been tested and are of high durability. So you do not need to frequently repair or check through them. However, proper maintenance can increase the lifespan of the LED strips, which is true. But in general, these fixtures are very user-friendly and don’t need too much maintenance.

How Can You Extend The Lifespan Of LED Strips? – Pro Tips

LED strips come with a rated life expectancy. But if the installation, power connection, and maintenance are not proper, your fixture won’t last as expected. Again, with proper care, you can extend your lifespan many times. Therefore, here I listed some pro tips using which you can easily use LED strips for years without facing any significant issues:

Keep the Lights Cool

Proper ventilation is a must to ensure cool LED strip operation. Ensure there is sufficient airflow in the room that takes the generated heat away from the LED. For proper heat management purchase LED strips from reputed brands that have integrated heat sinks. This will prevent heat buildup within the strip and disperse the heat away. Thus, maintaining a cool temperature extends the life expectancy of LED strips.

Choose High-Quality LED Strip Lights

High-quality LED strips are made of durable materials, such as 2-4 oz double-layer pure copper flexible PCBs. This ensures the smooth passage of significant current, reduces heat generation and helps the heat to dissipate more quickly. Besides, the LED chip, driver, PCB, adhesives, and all other components used in these fixtures are of high quality.

Therefore, using an LED strip from a reputable manufacturer will ensure proper heat management and overall operation. They further ensure reliability by offering certifications like- UL, ELT, CB, CE, etc. You can further ask for test reports that ensure the accuracy of claimed life expectancy. For instance, our LEDYi LED strips are LM80 incompatible, and we offer a lifespan of 50,000 hours.

Pick The Right Voltage Rating

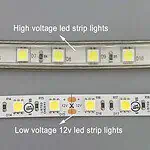

Always check the voltage rating of the LED strip to ensure it matches the voltage of the power supply. LED strips usually operate at low voltages, 12V and 24V. If you use a 12V power supply with a 24V LED strip, it will not glow. Again, connecting a 24V power supply to a 12V LED strip will overpower the LEDs and reduce their lifespan. Therefore, to ensure a longer lifespan, ensure the right voltage ratings for your LED strip.

Proper Installation and Mounting

You might feel it strange, but the installation and mounting do affect the lifespan of LED strips. LED strips are sensitive to vibration. If your installation is not robust enough, frequent movement can impact its lifespan. For this ensure the adhesive backing of the LED strip is strong enough to set perfectly on the surface. Besides, if you are mounting the fixtures on areas where it tackle maximum motion, use the clipping mounting technique.

Use of Lighting Controls and Dimming

LED strips wear out faster when they constantly run at full capacity. Thus, using a lighting controller or dimmer allows you to reduce the brightness from time to time. This reduces the loads on the fixture and extends life expectancy. Besides, many advanced technologies are also available that automatically detect the daytime and adjust the brightness accordingly.

Reduce the Wattage of LED Strip Lights

Heat is one of the main culprits that lowered the life expectancy of LEDs. Low-wattage LED strips indicate minimal heat generation. Using a low-wattage fixture will not overheat your LED chips. Thus, you can use them for a long time without facing any issues.

Use the Right IP Rating

IP ratings determine the light’s resistance to environmental conditions. A lower IP rating, like IP20, will quickly run out when installed outdoors. It won’t be able to resist the dust, wind, rain, and extreme conditions of the outer environment. Therefore, to ensure your fixture lasts longer, a sufficient IP rating is a must.

| Application | Suggested IP Rating |

| General indoor area | IP20 |

| Warehouse, factory without much dust | IP54 |

| General outdoor area | IP65 or IP66 |

| Underground | IP67 |

| Underwater | IP68 |

Use a Battery with Higher Capacity

Using battery-operated LED strips? The lifespan of such an LED strip directly depends on its battery capacity. Purchase batteries with higher capacity. This will power your LED strip for a long time, and, this way, increases its lifespan.

Regular Cleaning & Maintenance

Accumulation of dust and dirt in the LED strip impacts its operation. It hinders the light flow and decreases the brightness of the LEDs. To prevent this, you must clean the fixture regularly. But while cleaning, you must be careful with cleaning agents. Remember, all LED strips are not water resistant. So wet cleaning a low IP-rated LED strip can damage it. Besides, check the connections, wirings, and LED chips regularly to prevent damage. Thus, with proper maintenance, you can extend the longevity of LED strips.

However, installing LED strips outdoors requires greater maintenance as they are directly exposed to the natural environment. To ensure your LED remains safe and last longer, here are some of my suggestions that you must follow:

- Implement surge protection for your LED strip. This will prevent electric surges during storms.

- Purchase LED strips with appropriate IK ratings. This will ensure protection against impact. So, if the fixture gets hit by any object, your light will still work.

LED Strip Light Lifespan Vs. Lifespan of Other Lighting Technologies

LED strips use LED technology, which is definitely highly energy efficient and long-lasting compared to other lighting. With proper maintenance, they can last for 50,000 to 100,000 hours. In contrast, traditional lightings like incandescent have a lower lifespan, as short as 750 or 1,000 hours only. Again, fluorescent lights last for 7,000 to 15,000 hours. Though fluorescent lights have a higher lifespan than incandescent, they are nothing compared to LEDs.

| Light Technology | LED | Incandescent | Fluorescent |

| Lifespan | 50,000 to 100,000 hours | 750 or 1,000 hours | 7,000 to 15,000 hours |

Thus, an LED strip light can last about 10 times longer than fluorescent lights and about 50 times longer than incandescent lights.

Reason Why LED Strip Lifetime Claiming May Be Inaccurate

The lifetime of the LED strip lights is determined by LM-80 and TM-21 tests. These tests are to be conducted following specific parameters and conditions. If the manufacturer fails to follow this accuracy, the lifetime claim they make won’t be accurate. Here are some reasons for the wrong lifetime claiming by manufacturers:

a. Claiming Lifespan Beyond The Tested Hours

The thumb rule is to claim the lifetime 6x of the conducted test hours. For example, if you have done an LM-80 test of an LED stripe for 5,000 hours, the highest lifespan claim you can make is (5,000 x 6)= 30,000 hours. Even if the lights operate flawlessly after the tested duration, it’s not recommended to consider in calculating lifetime. Yet if you do so it ends up in inaccurate life expectancy and hampers brand image.

b. Using Condition Not Matching The Tested Temperature & Drive Current

The LM-80 test for LED strip longevity is conducted under a certain temperature and drive current. But if your LED strip is supplied with a higher current and operated at a high temperature, it will exceed the tested limits. Thus, the lifetime claims, as in LM-80, won’t fit anymore.

c. LM-80 and TM-21 Don’t Provide a Foolproof Guarantee

LM-80 and TM-21 don’t include factors like humidity or VOCs found in potting compounds for waterproof LED strips. These things directly impact the lifespan of LED strips, which questions LM-80 and TM-21. Besides, in the LM-80 test, there are rules to substitute specific materials for claiming the same test report. However, many manufacturers take advantage of this and use cheap, low-quality materials in mass production, which ends up in inaccurate lifespans.

LED Lifespan & When to Replace LED Strip?

LEDs behave differently than traditional fixtures like incandescent or fluorescent lights. Incandescent bulbs burn out as their lifespan ends and fluorescent lights start to flicker. Meanwhile LED doesn’t show such nature, it instead gradually lowers its light output. Therefore, LED strip lights work even after they are out of their lifetime and are not facing any “catastrophic” failure caused by a power surge or mechanical damage. You can use these fixtures until they are deemed too dim to use.

But what does “too dim to use” mean? Well, different lighting applications have different answers. However, the industry has somewhat arbitrarily decided that a 30% loss of light, or the remaining 70% of light, should be the standard. This is often referred to as the L70 metric. That is you can consider an LED strip to get too dimmed once it loses 30% of its initial lumen.

However, the application of the strip light matters here. For example, if you use LED strips as general lighting, you must replace them when you feel the light is not bright anymore. But in cases when LED strips are used as accent lighting or backlighting, you can still use them as they get dimmed. It somehow depends on your personal choice.

FAQs

Typically, LED strip lights have a lifespan ranging from 4 to 6 years. However, if you check the product packaging, many makers indicate the expected life duration in hours instead. Most LED items in the industry boast a standard life expectancy of around 50,000 hours.

Yes! One of the advantages of LED strip lights is that they consume less electricity than many traditional lighting options.

While it’s safe to use them for long durations, it’s important to note that prolonged usage can lead to overheating, which might reduce their lifespan.

When LED strip lights overheat, their components can get damaged, leading to reduced efficiency and a shorter overall lifespan.

To maximize their lifespan, it’s crucial to provide them with a proper power supply, manage their daily usage, and avoid overheating.

While LED strip lights are energy efficient, ensuring a proper power supply helps maintain their efficiency and longevity.

Reduced brightness, discoloration, or flickering can be signs of overheating or component damage in LED strip lights.

Yes, managing daily usage effectively, such as turning them off when they’re not needed, can help extend the life of your LED strip lights.

No, the lifespan of LED strip lights can vary based on factors like usage, heat exposure, and power supply quality.

LED strip lights typically last longer than many traditional light bulbs due to their energy efficiency and durable design.

LED strips burn out, but not suddenly, like incandescent bulbs. They gradually dim over time and burn out when their lifespan reaches its end.

The frequency of replacing an LED strip depends on its performance and lifespan. You can replace them immediately as they emit faint light. For example, if you buy an L70 fixture, its brightness will gradually reduce after the claimed lifespan. It will no longer be able to fulfill its claimed 70% of light emission. In this case, you can replace the lights if you find them not suitable for the application. In the meantime, if you face any issues like discoloring, flickering, buzzing noise, etc, you can replace it anytime.

Yes, you can leave the LED strip lights on 24/7. They won’t cause any possible hazards but will surely run out soon. Due to continuous use, you will need to replace them more frequently. Besides, overheating or overloading issues can also shorten the lifespan.

You can physically inspect to find if an LED is burned out. The first sign is they won’t lit anymore. Yet, turn on the switch and check for multiple times. If they no longer work, they will burn out. For further clarification, you can measure the voltage and current ratings using a multimeter.

Yes, LED lights last longer than other light fixtures like fluorescent or incandescent bulbs. They have an average life span of 50,000 hours that can be extended to 100,000 hours with proper maintenance.

Wrapping Up

While purchasing an LED strip, checking out its lifespan is a must. However, besides checking the hours, also look at ratings like L80 or L70. This will ensure better lumen capacity throughout the lifetime. Other factors to consider to elongate LED strips’ lifespan include voltage, power supply, heat maintenance, IP rating, IK rating, and more.

However, for the ultimate solution, go for LEDYi LED strips. All our fixtures are certified and tested. For instance, we offer a lifespan of more than 50000 hours for our single-color LED strips offers a lifespan of more than 50000 hours. So, you have used our lights for about 13 years for 10 hours daily. Besides, we also provide a 5-year warranty to ensure your money is invested in the right product. Therefore, place your order now with the most trusted and reliable LED strip manufacturer and supplier in China- LEDYi.