Looking for an attractive backlighting solution for commercial or advertising purposes? LED sheets are the best lighting option for this!

LED sheets are flat and flexible panel-shaped LED lights ideal for versatile uses. They work following the electroluminescence process as other LED lights. The most attractive feature of this LED sheet is that you can cut, fold, and bend them to your desired shape. They are available in different variations and sizes to meet your installation requirements.

Let’s explore more about LED sheets, their uses, installation process, troubleshooting common issues, and more:

What are LED Sheets?

LED sheets are flat-shaped flexible LED panel lights that can be cut, bent, folded, or wrapped to give desired shapes. This makes them suitable for signage, backlighting, architectural lighting, automotive lighting, etc. You can also mount them in screens, panels, or light boxes.

These lights come with double-sided adhesive backing for easy installation. Besides, you can also use nails or screws for mounting requirements. Connecting multiple sheets is also super easy. All these features make LED sheets excellent for versatile lighting needs.

How Do LED Sheets Work?

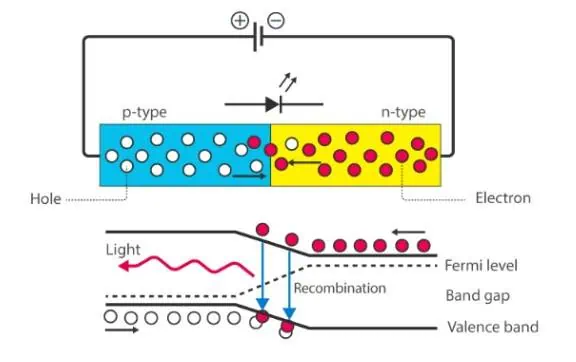

The LED chips are arranged throughout the flat PCB in LED sheet lights. These LED chips are made of semiconductors-

- P-type semiconductors (+’ve charged holes)

- n-type semiconductors (-‘ve charged electron)

When power is applied to the LED sheet light, the n-type semiconductor’s electron moves toward the p-type semiconductor’s holes. Similarly, the holes of the p-type semiconductor move towards the n-type semiconductors. Thus, they meet at a point, forming a p-n junction. As the holes and electrons recombine, they release energy as a form of light. This is how LED sheet lights work and emit light.

Types of LED Sheets

Single Color LED Sheet

Single-color LED sheets are the most basic types that bring up monochromatic color. These are available in different color temperatures like- 2700K, 3000K, 4000K, and 6000K. For warm lighting, choose low CCT; buy high CCT LED sheets for cool hues.

You may also read: 2700K VS 3000K: Which One Do I Need?

Tunable White LED Sheet

A tunable white LED sheet offers an adjustable CCT facility. You can change the hues from warm 2700K to cool 6000 K. Thus, tunable white LEDs give you greater control over lighting; you can adjust the light per your mood or requirement. For instance, while tasking, use bright, cool lighting. Again, when you are relaxing, switch to warm hues.

RGBW LED Sheet

RGBW LED sheets offer a full light spectrum and bright white lighting option. You can create dynamic hues and vibrant light colors using these LED sheets. Compared to traditional RGB LED sheets, RGBW LED sheets offer more color options with additional pure white lighting options. You can use these fixtures to light up bars, pubs, discos, stages, and other areas that require colorful lighting.

Addressable LED Sheet

Addressable LED sheets take your lighting to the next level. It has numerous programmable pixels that give you individual control over different sections of the panel. Thus, you can bring multicolor lights or rainbow-like effects. These lights can also sync with music, making them ideal for use in funky lighting functions.

LED Sheet VS Traditional Lighting Solutions

Energy Efficiency: Traditional lights, like incandescent bulbs, consume more electricity than LEDs. Most energy consumed is generated as heat, whereas only 5% is converted to visible light. This makes traditional lighting highly inefficient. In contrast, LED sheets convert 95% of the energy to light; only 5% is wasted as heat. Thus, LED sheets are a highly energy-efficient solution compared to traditional lighting.

Cost Comparison: Traditional lighting has a minimal initial cost, but it is not a cost-effective solution in the long run. These lights consume more energy, which increases electricity bills. Besides, they have a short lifespan, requiring frequent light replacement. In contrast, LED lights have a higher initial cost but are a cost-effective lighting solution in the long run. LED sheets save you electricity bills and don’t require frequent replacement.

Lifespan: In comparison to incandescent bulbs, LED sheets can last 30 times longer. They can glow for 25,000 to 50,000 hours. This can even extend up to 100,000 hours after boosting. In contrast, traditional incandescent light is only 1000 hours. So, you must buy about 50 to 100 incandescent bulbs to cope with an LED light’s lifespan.

Color Range: Traditional lights offer limited color ranges. For instance, incandescent lights are available in only three CCT ranges: daylight, cool white (3500K – 4100K), and soft white ( 2700K – 3000K). In contrast, LED sheet lights offer a wide range of CCT options (2200K–6000K). You can also get a full light spectrum color option with RGB lights.

LED Sheet VS Fluorescent Lamp

| Criteria | LED Sheet | Fluorescent Lamp |

| Energy Efficiency | High; uses less energy to generate light. Compared to fluorescent, they are 80% more energy efficient. | Low; uses less energy to produce illumination equivalent to LEDs. |

| Heat Emission | Only 5% of total energy consumption is emitted as heat | Almost 30% of energy is emitted as heat. |

| Initial Cost | High | Low |

| Overall Cost Effectiveness | Cost effective in the long run | Less cost-effective compared to LED. |

| Life Span | 25,000 to 50,000 hours | 10,000 to 15,000 hours |

| Control | Better control over light direction | Less control over light direction |

| Dimmability | Most LEDs are dimmable with compatible fixtures | Their dimming ability depends on the ballast |

Compared to fluorescent lamps, LED sheets are a better lighting solution. They are highly energy efficient, generate less heat, and have a longer life span. Using them further saves you electricity bills. Moreover, LEDs require less maintenance than fluorescent lights.

LED Sheet VS SMD LED Strip VS COB LED Strip

SMD and COB are two variants of LED strip lights based on the LED chip arrangement. They have a rope-like structure, whereas LED sheets are flat and paper-like. As all three use LED technology, their differences are visible in their physical features and applications.

| Criteria | LED Sheet | SMD LED Strip | COB LED Strip |

| ShapeOr Structure | Flat panels with embedded LEDs arranged together, make a paper-like structure. | LED chips are soldered on the circuit board, forming a rope-like shape. | Rope-shaped PCB with a continuous line of LEDs, bringing a seamless lighting effect. |

| Brightness | Provides uniform brightness over a large area | Brightness varies based on LED density and length | The continuous LED line offers high brightness and even light distribution |

| Light Quality | Uniform light; no visible spots | Hot spots are visible on low-density SMD LED strips | No visible hot spots |

| Cost | These are expensive due to their large panel size. | They are comparatively cheaper than LED sheets and COB LED strips. | Costlier than SMD LED strips |

| Cuttable | Yes | Yes | Yes |

| Applications | Ideal for backlighting, signage, and large panels where uniform light is needed | Ideal for accent lighting, under-cabinet lighting, and flexible installations | Ideal for high-quality, seamless lighting applications such as linear lighting, cove lighting, and high-end displays |

LED sheets are the best option for larger installations where you need to cover a larger surface area. All three are energy efficient due to their LED technology. However, LED strips are more flexible for shaping and bending than LED sheets.

Can You Cut These LED Light Sheets?

Yes, LED sheets are cuttable. They have cut points throughout the panels, which you can quickly cut into different sizes and shapes using a basic scissor. However, while cutting the sheets, you must be careful to follow specific marks. A wrong cut will destroy the circuit and LED, so the light will not glow.

Can You Bend or Fold Sheet LED?

LED sheets are super flexible, allowing you to bend or fold them easily. These are thin, paper-like light panels that you can fold in edges or bend to give desired shapes. However, you must follow the surface marks to bend or fold the sheets. A bend or folding over the LEDs will destroy the chip and break the circuit.

Here are some tips for bending the LED sheets without damaging it:

- Bend slowly and softly to create angles and shapes. This will minimize the stress on points that can break the internal circuits.

- Follow the manufacturer’s guidelines for minimum bend radius. The LED sheets will get damaged if you bend more than the limit.

- Avoid making sharp angles; instead, go for round edges to avoid damage.

- Some LED sheets have recommended directions for bending; check the manufacturer’s guide to know the correct order.

- Do a test bend with a small section of the LED sheet and connect it to the power source to check if it works. If everything goes right, bend the large or actual sheets you install.

How Do You Connect LED Sheets To The Power Supply?

Step 1: Connection Methods Between Sheets

First, connect the LED sheets before connecting them to the power supply. For this, you can go for any of the following two methods:

a. Series Connection

In a series connection, all the LED sheets are connected in a line. The arrangement is such that the positive end of the power supply is connected to the positive terminal of the first LED sheet. Next, the positive terminal of the first sheet is connected to the positive of the second. Similarly, all the positive terminals are wired together in a series.

The same goes for the negative terminals. All the LED sheets’ negatives are connected and joined to the negative pole of the power supply. Likewise, you can join up to 10 pieces (recommended) of LED sheets with a 24VDC power supply. Adding more than this will cause voltage drop issues.

Pros

- Less wiring is required.

- Easy circuit configuration

Cons

- Prone to voltage drop issues

- If one LED sheet fails, the entire connection will be disturbed.

b. Parallel Connection

In a parallel connection, all the LED sheets are directly connected to the power supply instead of being connected to other sheets. Here, all the LED sheets’ positive terminal is connected to the power supply’s positive terminal. Similarly, all the negative ends of the sheets are connected to the negative end of the power supply. Though this makes the configuration complex and requires more wiring, equal voltage is supplied to all the sheets.

Pros

- Allows you to control each LED sheet individually

- If one LED gets damaged, it will not impact the other fixtures

Cons

- It is a complex wiring process and requires a professional electrician to connect.

- Expensive process

Step 2: Power Requirements and Options

Next, consideration is to match the voltage rating of the LED sheets to the power source. LED sheets usually operate at a low voltage rating of 12V or 24V and maintaining voltage compatibility is a must. For instance, using a 24V power supply for a 12V LED sheet will overpower the LEDs. This will further heat them up, and eventually damage the lights. Again, a 12V power supply for a 24V LED sheet will not be enough. As a result, it won’t be able to light up a 24V LED sheet.

Step 3: Connect the LED Sheets to the Power Supply

Next comes the final step of powering the lights. Here, you need to join the wires from the LED sheets to the power supply, maintaining proper polarity. That is to connect the positive (+) ends of the sheets to the positive (+) terminal of the power supply. Similarly, connect the negative (-) of the sheets to the negative (-) of the power supply.

Step 4: Controllers and Dimming Capabilities

This step is optional. If you want a controller or dimmer, install it between the LED sheets and the power supply. In this case, make sure the dimmer and controller are compatible and have the right voltage and current ratings.

How Do You Connect Different Pieces of Sheet LED?

You have two options to join multiple pieces of sheet LED. These are as follows:

a. Using Solderless Connectors

Solderless connectors are a quick and easy alternative to soldering. Different types of solderless connectors can join the LED sheets. For instance, there are clip-on connectors and push-in connectors. However, the most convenient approach here is to use a plug-and-play connector. These connectors are specially designed for individual LED sheet types. These are pre-wired connectors. All you need to do is ensure compatibility and connect the final or last sheet to the plug-and-play connector. Thus, you can install it quickly and get a seamless lighting effect.

b. Soldering

Soldering is a more stable and robust alternative to using connectors. Here, you need to use a solder to pre-tin the connecting wires. Also, a small amount of solder should be applied to each solder pad of the LED sheets. Now position the tinted wires to the positive and negative terminals of the sheets and heat the tinted wire using a soldering iron. This will melt the metal parts of the solder pads and join the wire and the sheets together. When cooling, it will form a robust connection.

How Many LED Sheets Can Connect to One Power Supply?

You need to consider several factors to determine how many LED sheets can be connected to a single power supply:

1. Power Supply Capacity and Load Matching

Check the power consumption of individual LED sheets and sum them up. The total power consumption of all connected LED sheets should not exceed 80% of the power supply’s rated capacity. Considering this margin, you can find the maximum number of LED sheets to connect to a single power supply. Maintaining this load capacity range can further ensure reliable operation and extend the lifespan of the power supply.

2. Maximum Current on the Terminal (5A Limit)

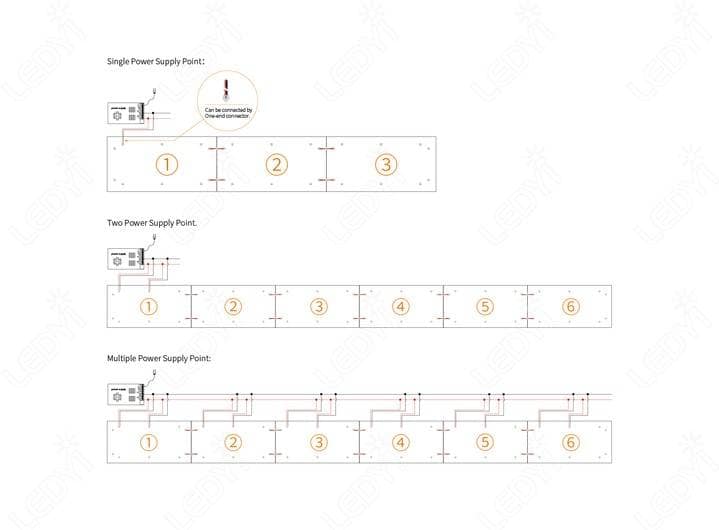

The terminal’s maximum current rating is a critical factor. If you need to connect more LED sheets, you should consider using multiple terminals to distribute the load. Additionally, the connection between the power supply and LED sheets and between LED sheets should utilize multiple terminals to avoid overloading. If you want to connect even more LED sheets, you can solder the wires directly to the LED sheets, allowing for a higher current to pass through.

3. Voltage Drop Considerations

Voltage drop issues are prominent when adding more sheets to the circuit. If this is the only limiting factor, connecting no more than 10 LED sheets in series is generally recommended. Beyond this, the voltage drop might cause uneven brightness or performance issues. In this case, you must add multiple power supplies to maintain even lighting.

By taking into account these factors—power capacity, terminal current limits, and voltage drop—you can determine the optimal number of LED sheets that can be safely connected to a single power supply.

How to Install LED Light Sheets?

Step 1: Surface Preparation

A dirty surface will hinder the placement of the LED sheets and affect its installation strength. For instance, the adhesive of the LED sheets will not stick to the surface properly. Eventually, within a short time, the sheets will come off. So, to avoid such a situation, use a wet cotton fabric to clean the dust and dirt particles from the installation surface. However, dry the surface completely after cleaning before proceeding to the next step.

Step 2: Cut And Connect LED Sheets

Thanks to the cuttable features of LED sheets, you can size the lights to your required length. Using a measuring tape, measure the length and width of the installation surface and cut the sheets accordingly. You will require multiple LED sheets for large installations. In this case, arrange the LED sheets and join them together using connectors or soldering, following the above segment of the article.

Step 3: Mounting The LED Sheets

You can follow three mounting techniques for installing LED sheets. These are as follows:

a. Adhesive

LED sheets usually come with double-sided adhesive backing, making your installation process much more convenient. You only need to peel off the tape and paste the sheets to the surface. Usually, 3M VHB mounting tapes are used here to ensure robust mounting.

b. Screws

You can nail and screw the LED sheets to mount it on the ceiling. This gives a strong and more reliable mounting solution compared to adhesive. In this method, you need to drill holes at the definite point of the installation surface and on the LED sheets. While drilling, make sure the holes match the size or diameter of the screw. In choosing the perfect screw for such installation, consider the surface material. If it’s a wooden or dry wood surface, use self-tapping screws. And use sheet metal screws if the surface is made of metal. Now, place the drilled sheets over the drilled surface and insert the screw in the holes. This will stick the sheets to the surface firmly.

c. Magnets

This method uses strong magnets to attach the LED sheets to the surface. Here, the magnet can be integrated with the LED sheets or the surface to give a quick installation. You can also use adhesive magnets for this purpose. Attach the magnets to the sheets or the surface and position them well— done. If you are using removable magnets, adjusting the position is easy.

Step 4: Wiring and Power Connection

Once you have mounted the LED strips, it’s time to wire them up and connect them to the power source. In this case, maintaining polarity is crucial. Ensure the positive wires from the LED sheets are connected to the positive terminal of the power source. Similarly, the negative end of light is connected to the negative of the power source. After fixing the wiring, turn on the switch, and the LED sheets will glow.

What are LED Sheet Lights Used For?

LED sheet lights’ flexible and panel-like structure suits them for versatile uses. These are as follows-

Backlighting

LED sheets are widely used as backlighting for digital displays, LCD screens, or advertisement panels on street or commercial spaces. Their bright illumination is suitable for such applications. You can also use LED sheets to backlight architectural elements like glass or acrylic.

Signage Lighting

The flexibility of LED sheet lights allows you to bend and shape them into different shapes and letters. You can also cut them to definite sizes. This feature makes them suitable for signage making. These panels can be used to make large commercial signage.

Large Scale Commercial Ceiling Lighting

LED sheets are the best solution to light up the entire ceiling and create even lighting. These large panels cover a large surface area, making them suitable for large-scale production. You can use these as ceiling lighting for shopping malls, theaters, offices, restaurants, etc.

Retail and Exhibition Displays

You can display the most attractive retail and exhibition products using LED sheets. For instance, they can be used as a backlight for display cases, shelves, or countertops in retail stores. You can also display them in jewelry shops, automotive showrooms, etc.

Art Installations and Creative Projects

You can use LED sheets to light artwork and creative projects. You can highlight sculptures, public galleries, museums, and more. The customized LED sheets themselves can be presented as artwork. You can use these Lightworks for festivals like Halloween, Christmas, etc.

Considerations When Choosing LED Sheets

Voltage & Wattage

Your LED sheets’ voltage must match the power source’s voltage. You must maintain compatibility for the proper functioning of the LEDs. This rating varies for different brands and manufacturers. For example, the LED sheets of LEDYi are available in the following power options:

| Type Of LED Sheets | Voltage | Power Option |

| Single Color LED Sheet | 24VDC | 11W, 22W, or 33W per sheet |

| Tunable White LED Sheet | 24VDC | 22W, 44W, or 66W |

| RGBW LED Sheet | 24VDC | 11W, 22W, and 33W per sheet |

You can customize these ratings as per your requirements; we are open to OEM and ODM facilities.

CRI & IP Ratings

CRI stands for Color Rendering Index. It determines the color accuracy of the LED sheet lights in comparison to natural lighting. Look for LED sheet lights that offer CRI>90 for the best result.

Again, depending on the environment of your LED sheet light installation, you need to pick the right IP rating. For indoor installation, a lower IP rating is ok. However, a higher IP rating is a must if your LED lights are mounted outdoors or come in close contact with water and moisture.

LED Spacing

The smaller the space between the LEDs, the more uniform lighting it will provide. Our LEDYi LED sheets contain 3550 LEDs per square meter. Thus, you get concentrated and even lighting without the issues of hot spots.

Customizability

The customization facility allows you to get personalized lighting solutions for your project. So, look for manufacturers that provide you with this flexibility. Look for the following tailor facility to get the ideal LED sheets for your installation:

- CCT

- Voltage

- Dimensions

- LED spacing

- Connectors

- Lens type, etc.

Quality Standards And Certifications

You must look for certification and test reports to ensure good-quality LED sheets. Here are some essential certificates that you must check before buying LED sheets-

- UL

- ETL

- CB

- CE-EMC

- CR-LVD

- RoHS

Reputable Manufacturers and Suppliers

Buying LED sheets from reputed brands ensures reliability. So, check the company’s background, experience in this field, reviews, services, etc. In this case, LEDYi is the most trusted Chinese company that manufactures LED sheets. We have been in this industry since 2011 and have experienced them producing high-quality customized LED sheets.

Warranty and Support Options

The warranty assures you that you are investing money in the correct product. If you face any issues with the LED sheets in due time, you can approve the manufacturer for a solution or replacement. Our LEDYi LED sheets offer a 5-year warranty. So, buy from us with confidence.

Troubleshooting Common Issues Of LED Sheets

1. LED Light Flickering

This may occur due to loose wire connectors, an insufficient power supply, or an incompatible dimmer. A voltage drop can also cause flickering issues if multiple LED panels are connected.

Solution:

- Inspect the wirings and ensure they are tightly connected

- Reduce the wiring length

- Check the dimmer and voltage compatibility

2. Overheating LED Light

Lack of ventilation around the LED sheets or installing them in hot places can overheat them. Besides, if the LED sheets are exposed to excessive voltage or current, they turn hot. This eventually damages the LEDs and reduces their lifespan.

Solution:

- Install the LED sheet maintaining the ventilation facility

- Ensure correct voltage and current to prevent overpowering

3. Displaying Wrong Color

A wrong color display may occur due to wrong wiring, especially in RGB LED sheets. Controller malfunction or any defect in the LED sheets can also result in a wrong color display.

Solution:

- Ensure wiring is correct for the color channels (R, G, B).

- Try using a different controller

- Look for any physical damage in the LED sheets and fix them ASAP

4. Lights Won’t Turn On

Lights may not turn on due to a faulty power supply, loose or wrong wiring, or any default in the LED sheets.

Solution:

- Using a multimeter test if the power source is supplying sufficient voltage

- Check the wirings

- Replace the LED sheets if nothing works

5. Buzzing Noise

An incompatible dimmer or faulty power source can cause a buzzing sound when the LED sheets operate. Again, using low-quality LEDs can also produce such noises.

Solution:

- Use a compatible dimmer for the LED sheet

- Purchase high-quality fixtures from reputed brands

- Ensure proper wiring

Besides the above-mentioned problems, LED sheets can also experience several other issues. For example, the remote may not work, the LEDs may be stuck to one color, there may be cutting issues, and more.

FAQs

The thickness of LED light panel sheets ranges from 1 to 3 millimeters. They are very thin but thicker than a sheet of paper, so they are not as thin as paper.

LED sheet lights can last for 25,000 to 50,000 hours. However, boosting or proper maintenance can last up to 100,000 hours. This makes them long-lasting compared to other traditional forms of lighting.

The LED technology used in LED sheet lights is highly energy efficient. They consume less energy than traditional light fixtures like incandescent or fluorescent bulbs, about 95% less energy than traditional lights, and save electricity bills. All these factors make them an efficient lighting solution.

LED sheets are flexible, large panels that can be used for large-scale lighting needs. They are excellent for signage, backlighting, commercial lighting, and display.

Yes, weather-resistant LED sheet lights are suitable for use outdoors. For this, consider the IP rating. A higher IP rating means better protection against dust and moisture.

With your smartphone, you can use a compatible app or controller to control LED sheet lights. This allows you to control the lighting via Wi-Fi or Bluetooth. Thus, you can change the color, dim the lighting, and turn it on or off from anywhere using your smartphone.

You can dim the LED light sheets using compatible dimmers such as DALI, 0-10V, and DMX. However, before choosing a suitable dimmer, consider your LED sheets. An incompatible dimmer can have flickering issues, displaying the wrong color, buzzing sounds, etc.

Conclusion

LED sheets give your space a sleek look that can enhance its overall beauty. You can use them for ceiling lighting in commercial spaces, backlighting, or displaying retail products. However, before purchasing LED sheets, check the voltage, power ratings, color of the light IP, and CRI ratings. Also, look for certification to ensure trustworthy products.

Nevertheless, for the best LED sheets, LEDYi is your ultimate solution. Our LED sheets are of high identity that eliminates hotspots, come with a plug-and-play connection, and have double-sided adhesive backing for convenient installation. They also support nailing and drilling. If you need any customization facility, OEM and ODM, we are also open to it. We further offer you a 5-year warranty and full-time customer support. So, request for a free sample ASAP!