Unlock the power of COB LED strip lighting, the perfect choice for seamless, efficient lighting. Find out why COB LED strips are transforming both professional and personal lighting spaces.

COB LED strips are known for their tightly packed LEDs, which deliver smooth, consistent light without the dotted appearance typical of traditional SMD LED strips.

Keep reading to learn about the versatile uses and key advantages of choosing COB LED strip technology for your lighting requirements.

Understanding COB LED Technology

What Does COB Mean In LEDs?

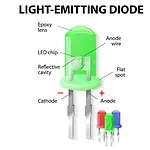

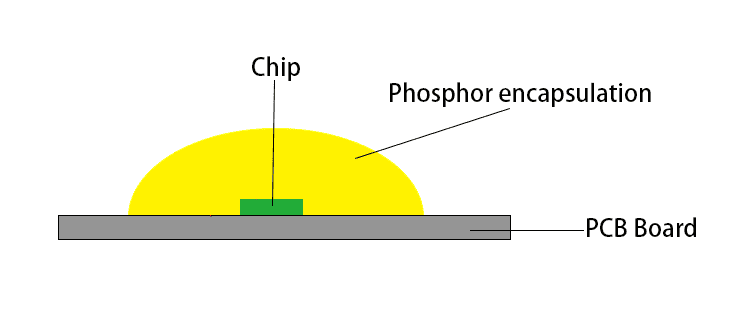

COB (Chip on Board) LED technology represents a significant advancement in the field of lighting. Unlike traditional LED lighting, which uses multiple individual LEDs, COB technology mounts numerous LED chips directly onto a substrate to form a single module. This innovative approach allows for a higher density of LED chips, resulting in a light output that is both brilliantly bright and stunningly uniform.

The essence of COB’s superiority lies in its compactness and efficiency. By packing a multitude of chips into a small area, COB LEDs produce an intensely bright light from a compact footprint. This not only enhances luminous efficiency but also facilitates seamless integration into various design aesthetics, making COB LED strips an ideal solution for a wide range of lighting applications.

What Are The Benefits Of COB LED Over SMD LED?

COB LED technology boasts several advantages over traditional LED (Light Emitting Diode) solutions, making it a preferred choice for many lighting applications. One of the most notable benefits is its ability to provide a more uniform light output. Traditional LEDs often produce a spotted or pixelated effect, especially when used for direct illumination. In contrast, COB LEDs, with their closely packed chips, emit a smooth and consistent light beam, eliminating the harsh spots and shadows often associated with individual LEDs.

Another significant advantage is the increased luminous efficacy of COB LEDs. Thanks to the high packing density of LED chips on the COB module, these lights can achieve higher brightness levels using less energy. This not only makes COB LEDs more energy-efficient but also reduces the heat generated during operation, extending the lifespan of the lighting fixture. For more information about luminous efficacy, please read Lumen to Watts: The Complete Guide.

COB LEDs also offer enhanced color rendering, which means they can reproduce colors more accurately compared to traditional LEDs. This feature is particularly important in applications where color fidelity is critical, such as in retail displays, art galleries, and under-cabinet lighting in kitchens. For more information about color rendering, please read What is CRI and TM-30-15: A New Method for Measuring Color Rendition.

Lastly, the robust design of COB LEDs contributes to their durability and reliability. With fewer solder joints and a solid substrate that supports the LED chips, COB technology is less prone to failure, ensuring a longer operational life and reducing maintenance costs over time.

Here is a table to highlight the key differences between COB and SMD LEDs:

| Light Output | Uniform, smooth | Spotted, pixelated |

| Efficiency | Higher luminous efficacy | Lower luminous efficacy |

| Color Rendering | Enhanced, more accurate | Less accurate |

| Design | Fewer solder joints, robust design | More solder joints, less durable |

| Heat Generation | Lower | Higher |

| Lifespan | Longer | Shorter |

| Applications | High-end lighting, retail, art | General lighting, consumer goods |

For more information, please visit SMD LED vs. COB LED: Which One Is Better?

What Is a COB LED Strip?

A COB (Chip On Board) LED strip is a lighting technology that packs many LED chips closely together on a single circuit board. This design creates a smooth, continuous light without gaps or hotspots. Unlike traditional LED strips, where individual LEDs are visible and spaced apart, COB LED strips feature a denser array of LEDs. This results in a more uniform and seamless line of light, eliminating noticeable hotspots. COB LED strips are ideal for applications requiring smooth and continuous illumination. They are known for their high brightness, efficiency, and durability, making them popular for both commercial and residential lighting projects.

Features Of COB LED Flex Strips

Seamless Illumination

One of the standout features of COB LED flex strips is their ability to produce seamless illumination. Unlike traditional LED strips that can create a dotted line effect, COB strips emit a smooth and continuous light, thanks to the high density of LED chips. This feature is especially beneficial for applications where a uniform light output is critical, such as under cabinet lighting, cove lighting, or any setting where the light source is visible. The seamless glow of COB LED strips enhances the aesthetic appeal of spaces by eliminating the spottiness associated with other types of LED lighting.

High Light Density

COB LED flex strips are characterized by their high light density, which refers to the number of LED chips packed closely together across the length of the strip. This design allows for a brighter output per unit length compared to traditional LED strips. The increased brightness makes COB strips an excellent choice for areas requiring high levels of illumination, such as task lighting in kitchens or offices, without the need for additional light sources.

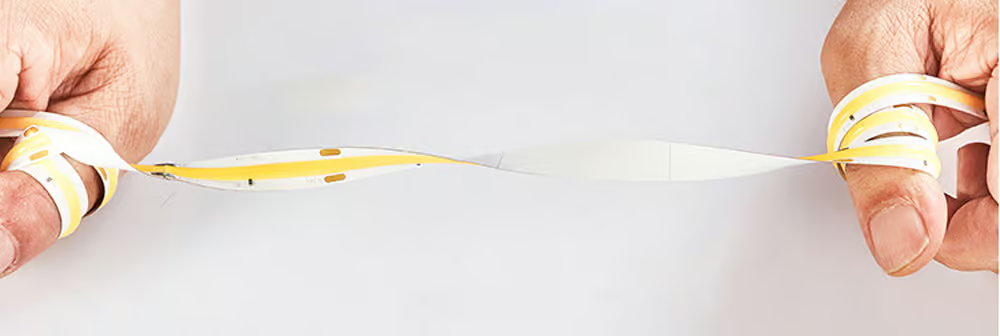

Flexibility

The flexibility of COB LED strips is another significant advantage. These strips can be bent and twisted to fit various shapes and surfaces, making them incredibly versatile for creative lighting designs. Whether wrapping around curves, conforming to irregular shapes, or fitting into tight corners, COB LED strips adapt easily, providing consistent illumination without compromising on light quality or intensity.

Wide Beam Angle

What is the Beam Angle of a COB LED Strip?

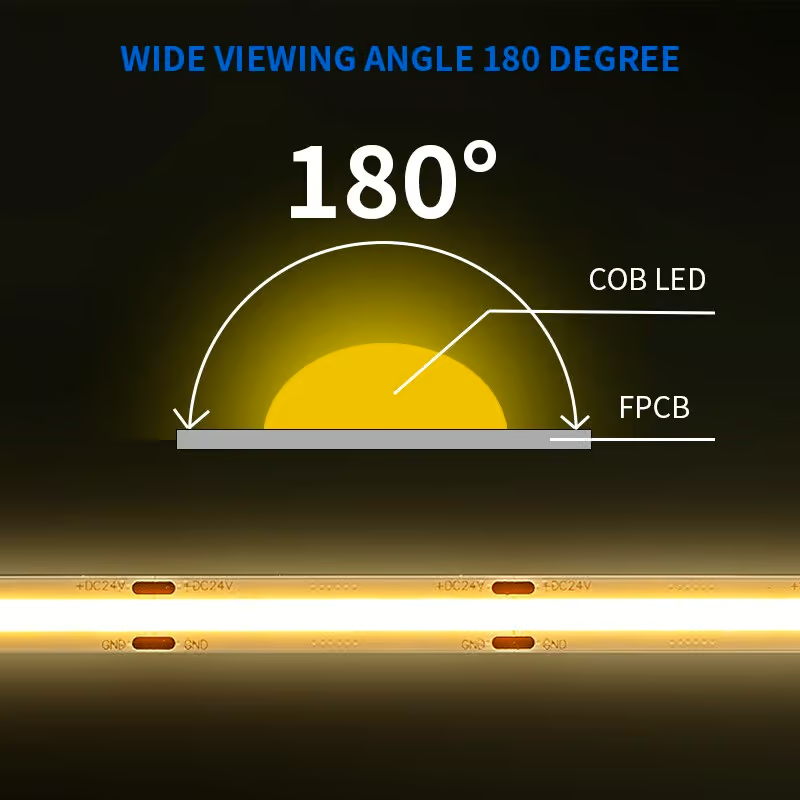

COB LED strips offer a wide beam angle of 180 degrees.

This wide angle ensures broad and even light distribution, making them ideal for lighting large areas uniformly. The broad coverage reduces shadows and enhances the visual comfort of a space. Whether used for general ambient lighting or specific task areas, the wide beam angle of COB LED strips ensures that light reaches every corner. This makes them a practical choice for both residential and commercial settings. For more information, please check Everything You Need To Know About Beam Angle.

Energy Efficiency And Longevity

Energy efficiency and longevity are key features of COB LED strips. Despite their high light output, these strips consume less power than traditional lighting solutions, thanks to the efficiency of COB technology. Additionally, COB LED strips are designed to last longer, with many models offering thousands of hours of operation. This durability, combined with their low energy consumption, makes COB LED strips a cost-effective and sustainable lighting choice.

Cuttable And Customizable

Is a COB LED Strip Cuttable?

Yes, a COB LED strip is cuttable and customizable, allowing for easy integration into custom lighting designs.

With designated cutting points along the strip, users can trim their COB LED strips to the exact length required for their project, ensuring a perfect fit every time. This feature, along with the availability of various connectors and accessories, makes it simple to create tailored lighting solutions that meet specific design needs.

Dimmable

Finally, the dimmable capability of COB LED strips adds to their appeal. Being able to adjust the brightness of the lighting allows for the creation of different atmospheres and moods in a space, from bright and energetic to soft and relaxing. This flexibility makes COB LED strips suitable for a wide range of applications, enhancing both the functionality and ambiance of any environment. For more information, please check How to Dim LED Strip Lights.

Advantages and Disadvantages of COB LED Flex Strips

What Are The Advantages Of COB LED Strips?

Uniform Lighting, No Lighting Dots, Even Without Aluminum Profiles

One of the most praised advantages of COB LED flex strips is their ability to deliver a uniform light output without the LED lighting dot effect, even in installations where aluminum profiles are not used. This results in a cleaner, more consistent light appearance that enhances the aesthetics of any space. It’s a key factor for designers and homeowners who seek sleek and smooth lighting effects without visible dots or harshness. For more information, please check Ultimate Guide To Aluminum Profile For LED Strip.

More Flexibility

COB LED strips are remarkably flexible, allowing for creative installations in a variety of settings. This flexibility enables designers and DIY enthusiasts to weave lighting into intricate designs and tight spaces where traditional LED strips might not fit. The adaptability of COB strips opens up new possibilities for customized lighting solutions that can wrap around curves, fit into narrow alcoves, or highlight architectural features with precision.

More Stable, Fewer Problems

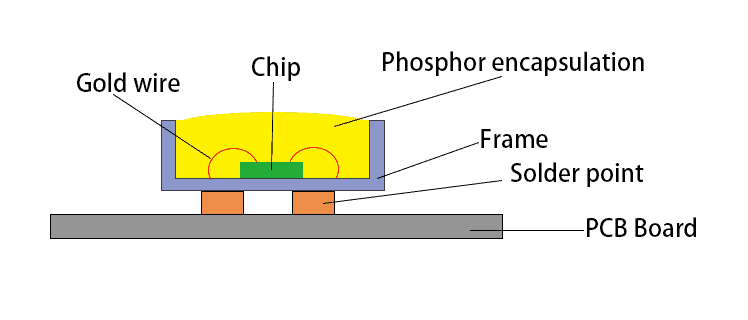

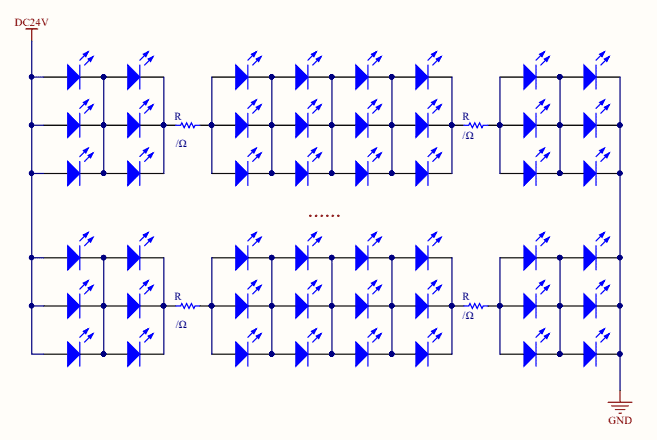

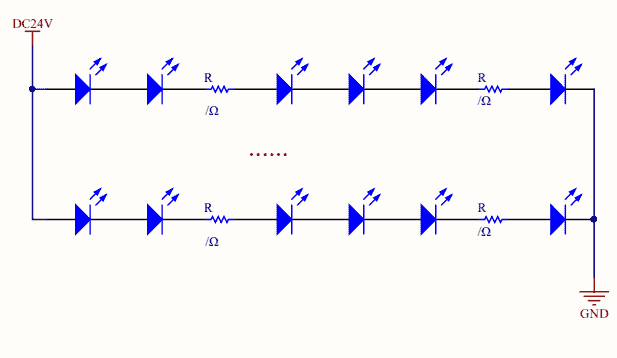

Direct Chip Attachment: COB LED strips utilize a chip directly attached to the FPCB (Flexible Printed Circuit Board), eliminating the need for gold wires, which are a common point of failure in traditional SMD LED strips.

Gold Wire Issues In SMD LEDs: Many problems with traditional SMD LED strips arise from the gold wire inside the LED beads. The gold wire is very delicate and can easily break, leading to non-illuminated chips and strip failure. For more information about LED strip problems, please read Troubleshooting LED Strip Problems.

Innovative Circuit Design: The circuit design of COB strips employs a unique approach where three chips are first connected in parallel as a group. These groups are then connected in series to form a continuous strip. This configuration ensures that even if one or two chips within a group fail, the rest of the strip remains illuminated.

High Chip Density: With a high density of chips per meter (up to 480 chips), COB LED strips ensure that the failure of 1-2 chips does not create dark areas or affect the overall use of the strip. This high chip count contributes to the uniformity and reliability of illumination.

Wide Emitting Angle

The wide emitting angle(180 degree beam angle) of COB LED strips provides expansive coverage, ensuring that light is distributed evenly across a broad area. This feature is particularly beneficial in settings where uniform illumination is crucial, such as in task lighting, ambient lighting, or when highlighting large surfaces. The wide angle helps eliminate shadows and dark spots, creating a more inviting and well-lit environment. For more information about beam angle, please read Everything You Need To Know About Beam Angle.

Anti-vulcanization

COB LED strips are designed with materials that resist vulcanization, a process that can cause traditional rubber and plastic components to harden and deteriorate over time when exposed to sulfur and other chemicals. This resistance extends the aesthetic and functional life of the strip, ensuring that it remains flexible and maintains its integrity, even in challenging environments.

Stronger Anti-static Capability

With a stronger anti-static capability, COB LED strips are less susceptible to damage from static electricity, which can be a common issue in dry climates or during certain times of the year. This feature helps to protect the delicate electronic components within the strip, reducing the risk of premature failure and extending the overall lifespan of the lighting solution.

What Are The Disadvantages Of COB LED Strips?

Difficult to Maintain Color Consistency, No Binning Machine Available

One of the challenges with COB LED strips is the difficulty in maintaining the consistency of color across different batches, as they do not use a BINNING machine process. This can lead to slight variations in color temperature and hue, which may be noticeable in certain applications, especially when adding new sections to an existing installation. For more information, please check What Is LED Binning?

Lower Luminous Efficiency

While COB LED strips offer many advantages, they may exhibit lower luminous efficiency compared to some high-power traditional LED strips. This means that, in some cases, they may produce less light per watt of energy consumed. However, for many applications, the superior quality of light and the benefits of uniformity and aesthetics outweigh this factor.

Lower Power

COB LED strips typically operate at lower power levels compared to some traditional LED strips designed for high-brightness applications. This characteristic is not necessarily a drawback but something to consider when planning projects that require intense levels of illumination. In most residential and commercial settings, however, COB LED strips provide ample light for creating inviting and well-lit spaces.

Color Variations on White Surfaces

When COB LED strips are directed at white walls, there can be a slight color difference between the edges and the center of the illuminated area. This phenomenon, known as yellow banding, causes the edges to appear slightly yellowish. Although this effect is minor and not easily noticeable unless examined closely, it is something to be aware of in specific lighting applications.

Types of COB LED Strips

Single Color COB LED Strips

Single color COB LED strips are the simplest form of COB lighting, designed to emit light in one consistent color. These strips are perfect for creating ambient lighting, accentuating architectural features, or providing task lighting in spaces where a specific color tone is desired. They are available in a range of colors, including warm white, cool white, and daylight, allowing for customization to match or enhance the mood of any room.

Tunable White COB LED Strips

Tunable white COB LED strips offer the ability to adjust the color temperature of the light from warm to cool white. This feature enables users to change the lighting atmosphere according to the time of day, activity, or personal preference, making it a versatile choice for environments where the mood and functionality of lighting need to be adaptable. For more information, please check Tunable White LED Strip: The Complete Guide.

Dim to Warm COB LED Strips

Dim to Warm COB LED strips provide a unique lighting solution that mimics the dimming characteristics of traditional incandescent bulbs, where the light becomes warmer as it is dimmed. This technology allows users to lower the brightness level while simultaneously transitioning the color temperature from a brighter, cooler white to a softer, warmer white. This capability enhances the ambiance of any space, offering the flexibility to create a cozy and inviting atmosphere simply by adjusting the light intensity. Ideal for residential settings, hospitality environments, and anywhere the aim is to achieve a comfortable and relaxing mood, Dim to Warm COB LED strips combine the efficiency of LED technology with the nostalgic appeal of classic lighting. For more information, please check Dim To Warm – What It Is and How Does It Work and What is the Difference Between Dim to Warm LED Strips and Tunable White LED Strips.

RGB COB LED Strips

RGB COB LED strips are capable of producing a wide spectrum of colors by blending red, green, and blue light. This type allows for dynamic lighting setups and the ability to switch between an array of colors, making it ideal for entertainment areas, gaming setups, and spaces where creative and vibrant lighting effects are desired. For more information, please check What is RGB Lighting? and RGB vs. RGBW vs. RGBIC vs. RGBWW vs. RGBCCT LED Strip Lights.

RGBW COB LED Strips

Expanding upon the RGB model, RGBW COB LED strips incorporate an additional white chip, enabling them to produce pure white light or enhance the brightness and color accuracy of mixed colors. This addition makes RGBW strips a great option for situations requiring both colored and high-quality white lighting.

RGBCCT COB LED Strips

RGBCCT COB LED strips combine RGB capabilities with Correlated Color Temperature (CCT) control, offering the most flexibility in color and temperature adjustment. These strips can create any color, including different shades of white, making them suitable for advanced lighting designs that require precise control over both mood and ambiance. For more information, please check RGB vs. RGBW vs. RGBIC vs. RGBWW vs. RGBCCT LED Strip Lights.

Addressable COB LED Strips

Addressable COB LED strips allow individual control over segments of the strip, enabling complex lighting effects, animations, and color changes. These strips are perfect for creating dynamic visual displays, accent lighting, and customized lighting sequences in both commercial and residential settings. For more information, please check The Ultimate Guide To Addressable LED Strip.

Free Cutting COB LED Strips

Free cutting COB LED strips are designed with flexibility in mind, allowing users to cut the strip at any point without damaging the remaining LEDs. This feature is particularly useful for custom lighting projects where precise lengths are required.

Side Emitting COB LED Strips

Side emitting COB LED strips emit light from the edge of the strip, making them ideal for indirect lighting applications such as cove lighting, where the strip itself is hidden from view. This orientation creates a soft, diffused light effect that can enhance the ambiance of a space.

Ultra Narrow COB LED Strips

Designed for applications where space is limited, ultra narrow COB LED strips are slimmer than standard strips, making them suitable for tight spaces where traditional strips might not fit, such as in detailed architectural models or intricate design elements.

Reel To Reel COB LED Strips

Reel to reel COB LED strips stand out in the LED lighting market for their innovative manufacturing process and superior performance. Unlike traditional LED strips that are assembled and soldered in sections, reel to reel COB LED strips are produced in a continuous process without any soldering joints across the entire reel. This cutting-edge approach offers several key advantages:

No Soldering Joints: The absence of soldering joints throughout the reel eliminates the risk of false soldering or breakage that can occur during the production process. This leads to a more reliable and consistent product, reducing the likelihood of failures.

Enhanced Durability: With no solder joints to weaken their structure, reel to reel COB LED strips are more durable and less susceptible to damage during installation or use. This durability is crucial in commercial and industrial applications where long-term reliability is essential.

Easy Customization: These strips can be cut to any desired length, offering unparalleled flexibility to meet specific lighting requirements. The 50-meter long packaging without soldering joints allows for seamless integration into various spaces without worrying about connection points.

Accurate Sizing: The continuous production process ensures that each reel of COB LED strip maintains consistent sizing without deviations. This accuracy is beneficial in applications where precise lengths and uniform appearance are critical.

Effortless Installation: The solder-free design simplifies the installation process, making it easier and faster to deploy the lighting. This feature, combined with solder-free connectors, enhances the ease of use and reduces installation time.

High Performance: Reel to reel COB LED strips are not only about convenience and durability but also about performance. They offer high luminous efficacy, with certain series providing up to 160 lumens per watt, and a wide 180-degree emitting angle for effective illumination.

High Efficiency COB LED Strips

High efficiency COB LED strips are engineered to provide the maximum amount of light output while minimizing energy consumption. These strips are perfect for eco-conscious installations where both performance and sustainability are key considerations.

Constant Current COB LED Strips

Constant current COB LED strips are designed to maintain a consistent brightness level across the entire length of the strip, even if the voltage fluctuates. This feature ensures uniform lighting and is especially beneficial for longer strip runs, where voltage drop might otherwise cause dimming at the end of the line.

48V Long Run COB LED Strips

48V long run COB LED strips are designed for installations that require long lengths of continuous lighting without significant voltage drop. The higher voltage allows these strips to maintain consistent brightness over greater distances, making them suitable for large-scale projects such as commercial spaces and outdoor areas.

Double Row COB LED Strip

Wide COB LED Strip is designed for spaces needing broad and seamless lighting. Its wider design provides an expansive, dot-free illumination, ensuring uniform light across its entire surface.

Applications of COB LED Strips

Residential Lighting

COB LED strips are a versatile lighting solution for residential settings, offering a wide range of applications to enhance the comfort and aesthetics of a home. They can be used for under-cabinet lighting in kitchens, providing a uniform light source that illuminates countertops without shadows or hotspots. In living rooms, COB strips can create ambient lighting that adds warmth and depth to the space, or they can be used for accent lighting to highlight artwork, architectural features, or shelving.

Commercial Lighting

In commercial environments, COB LED strips serve both functional and aesthetic purposes. Retail stores benefit from the even, bright illumination of COB strips for display lighting, making products more appealing while ensuring accurate color representation. Offices can use COB LED strips for task lighting, reducing eye strain and improving productivity, or for general ambient lighting that creates a welcoming atmosphere for employees and visitors alike.

Industrial Applications

COB LED strips are also suitable for industrial applications, where their durability and long lifespan make them ideal for lighting in manufacturing facilities, warehouses, and workshops. Their uniform light output improves visibility and safety, while their energy efficiency and low maintenance requirements contribute to reduced operational costs.

Creative and Decorative Uses

The flexibility and variety of COB LED strips open up a world of creative and decorative possibilities. They can be used in architectural lighting to accentuate lines and shapes, in landscape lighting to enhance outdoor features, or in entertainment settings for dynamic, colorful effects. Event planners and interior designers often incorporate COB LED strips into their projects to create immersive environments and memorable experiences.

How is COB LED Strip Produced?

The manufacturing process of COB LED flexible strips is a meticulous sequence designed to ensure quality, efficiency, and durability. Here is a revised outline reflecting the detailed stages involved:

Expanding Chips and Die Bonding

Initially, high-quality LED chips are selected for their efficiency, color consistency, and longevity. These chips are then expanded and precisely bonded onto a flexible PCB (Printed Circuit Board), a substrate chosen for its durability and thermal conductivity. This direct mounting, known as die bonding, allows the strips to be flexible and effectively dissipate heat.

Attaching Resistors onto FPCB

Following the chip mounting, resistors are attached to the FPCB using an automated process. These resistors are crucial for regulating the current flow through the LED chips, ensuring stable performance and preventing overheating.

Reflow Process

The assembled PCB, now with chips and resistors in place, undergoes a reflow process. This involves exposing the PCB to high temperatures, over 65 degrees Celsius, solidifying the connections and ensuring the components are securely bonded to the board.

Applying Fluorescent Powder Glue

A specially formulated mixture of fluorescent powder glue is prepared. This glue is essential for the encapsulation process, providing protection to the LED chips and resistors while enhancing the light’s color quality and uniformity.

Auto Glue Application

Using an automatic glue machine, the fluorescent powder glue mixture is precisely dropped onto the surface of the chips and resistors. This step ensures even coverage and optimal encapsulation of each component.

Curing in the Oven

After the application of the glue, the COB LED strip is placed into an oven. The curing process solidifies the glue, securing the encapsulation and ensuring the strip’s components are well-protected against physical and environmental factors.

Quality Control Testing

Once cooled, the COB LED strip undergoes rigorous quality control testing. This includes checking for consistent light output, color accuracy, and overall performance to ensure the strips meet the high standards expected.

Soldering and Reeling

The strips are then soldered into lengths, typically 5 meters per reel or according to customer specifications, ensuring easy installation and use. This step also includes adding adhesive backing and connectors for power and control.

Aging Test and Final QC

An aging test is conducted to simulate extended use, followed by a final quality control check. This thorough testing phase guarantees the reliability and longevity of the COB LED strips.

Packing and Shipping

Finally, the COB LED strips are carefully packed and prepared for shipping, ready to illuminate various spaces with their efficient, consistent, and high-quality light output.

This detailed manufacturing process ensures that COB LED flexible strips not only meet but exceed performance and durability standards, providing a superior lighting solution for a wide range of applications.

How to Choose the Right COB LED Strip

Selecting the appropriate COB LED strip for your project is crucial to achieving the desired aesthetic, functional, and efficiency goals. Here are refined considerations to guide your choice, including additional factors like voltage, IP rating, PCB width, and color-changing options:

Color Temperature and Color Rendering Index (CRI)

- Color Temperature: Choose based on the atmosphere you want to create; warm white (2700K-3000K) for a cozy ambiance, or cool white (5000K-6500K) for clearer, task-oriented lighting. For more information, please check How to Choose LED Strip Color Temperature?

- Color Rendering Index (CRI): Opt for a higher CRI (above 80) to ensure colors appear naturally and vividly, crucial for spaces where color accuracy is important. For more information, please check What is CRI and TM-30-15: A New Method for Measuring Color Rendition.

Brightness (Lumens)

- Evaluate the lumens per meter (or foot) to match the lighting needs of your environment. Brighter isn’t always better; balance brightness with the intended use. For more information, please check Candela vs Lux vs Lumens.

Power Consumption and Efficiency

- Check the watts per meter (or foot) to assess energy use. Opt for higher efficiency strips to save on electricity bills while maintaining brightness.

Flexibility and Installation Requirements

- Consider the strip’s flexibility for installation around corners or curved surfaces. Additionally, review if specific mounting profiles are needed for optimal heat dissipation and light diffusion.

Dimmability and Control Options

- Ensure compatibility with dimming controls or smart home systems if you intend to adjust brightness or color temperature, enhancing the versatility of your lighting scheme.

Voltage

- Select the correct voltage (commonly 12V or 24V) for your application. Higher voltage options may offer longer run lengths without voltage drop, important for expansive installations. For more information, please check What is LED strip voltage drop?

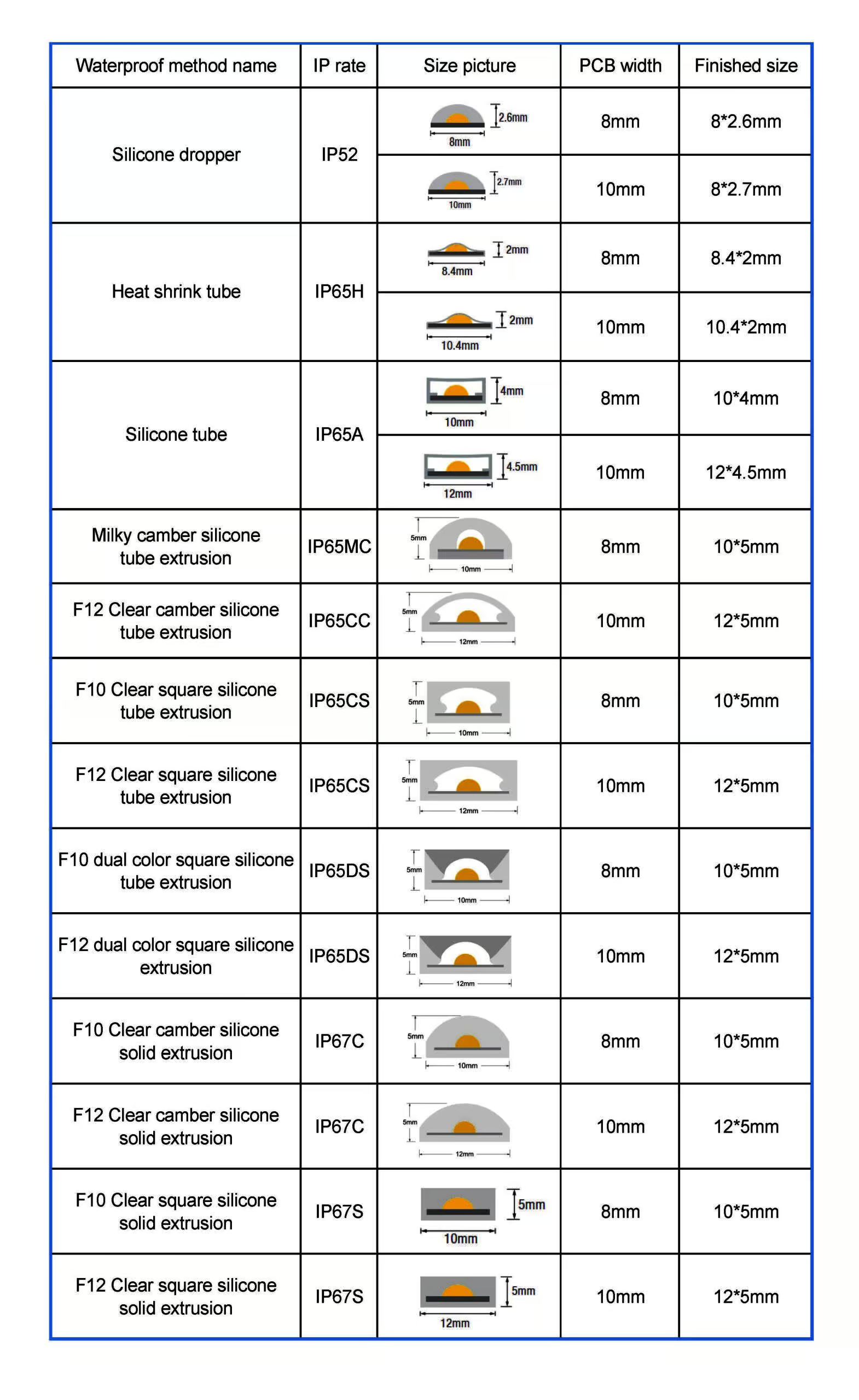

IP Rating

- For installations in moist or outdoor environments, choose a strip with a suitable IP rating (e.g., IP65 or higher) to ensure protection against water and dust ingress. For more information, please check IP Rating: The Definitive Guide.

Is COB LED Strip Waterproof?

Yes, we offer various waterproof ratings for outdoor use.

PCB Width

- The width of the PCB can impact installation flexibility and heat management. A wider PCB might offer better heat dissipation, important for longevity and consistent performance. For more information, please check What LED Strip Widths Are Available?

Color Changing Options

- If dynamic lighting is desired, consider strips with color-changing capabilities:

- Single Color: For fixed, uniform lighting.

- Tunable White: Allows adjustment from warm to cool white.

- RGB: Offers a full spectrum of colors.

- RGBW: Combines RGB with pure white for enhanced color mixing and brighter whites.

- COB LED Strips for Special Applications: Some strips are designed with unique features, such as side-emitting, ultra-narrow, or high-intensity options, catering to specific design requirements.

Length and Cut Points

- Verify the maximum continuous run length to ensure consistent brightness. Cut points indicate where the strip can be safely trimmed, allowing customization to fit precise measurements.

By meticulously assessing these aspects, you’ll be equipped to choose a COB LED strip that not only meets but exceeds your project’s lighting requirements, ensuring both aesthetic appeal and functional efficiency.

Installation and Maintenance

How to Cut COB LED Strip

Cutting a COB LED strip to the desired length is a straightforward process, but it requires precision to ensure the functionality of the strip is maintained. Here’s how to do it:

Step 1: Measure and Mark

First, determine the length of COB LED strip you need for your project. Measure the area where you plan to install the strip and mark the cutting point on the strip itself. COB LED strips have designated cutting points, usually marked with a line or scissors icon, indicating where it’s safe to cut.

Step 2: Use Proper Tools

Use a pair of sharp scissors or a cutting tool specifically designed for LED strips. Cutting at the designated points ensures that you do not damage the electrical circuit or the LEDs themselves.

Step 3: Test Before Installation

After cutting, it’s important to test the strip to ensure it still functions properly. Connect the cut strip to a power source using the appropriate connector. This step verifies that the strip lights up and that all sections are working as expected.

How to Install COB LED Strip Lights

Installing COB LED strip lights can enhance any space, but proper installation is key to achieving the best results. Here’s a simplified guide:

Step 1: Prepare the Surface

Ensure the surface where you plan to install the strip is clean, dry, and smooth. Any dirt or moisture can affect the adhesive, and a rough surface may prevent the strip from sticking properly.

Step 2: Plan Your Layout

Before removing the adhesive backing, plan the layout of your strip. Consider where you will start and end, how you will navigate corners, and where your power source will be located.

Step 3: Adhere the Strip

Peel off the adhesive backing and carefully stick the strip to your chosen surface, pressing firmly along its length. If your strip doesn’t come with an adhesive backing, you may need to use mounting clips or an appropriate adhesive.

Step 4: Connect to Power

Once the strip is in place, connect it to the power supply. If you’re using a dimmer or controller, make sure it’s compatible and properly connected between the power supply and the strip.

How to Connect COB LED Strip Lights

Connecting COB LED strip lights, whether extending a length or adding a power supply, is crucial for a successful installation. Here’s a simplified approach:

Step 1: Choose the Right Connector

Select a connector that matches the width and pin configuration of your COB LED strip. There are solderless connectors available that make the process easier, especially for those not comfortable with soldering.

Step 2: Open the Connector

Open the connector clamp. For solderless connectors, ensure the pins align with the contact points on the strip. If soldering, prepare the strip and wires accordingly.

Step 3: Insert and Secure

Insert the end of the COB LED strip into the connector, ensuring a snug fit. Close the clamp to secure the strip in place. For a soldered connection, solder the wires to the strip’s contact points, then insulate with electrical tape or heat shrink tubing.

How Do I Connect My COB LED Strip to My Power Supply?

Properly powering COB LED strips is essential for optimal performance and longevity. Here’s a basic guide:

Step 1: Calculate Power Requirements

Determine the total wattage of your COB LED strip installation to choose the right power supply. Add a 20% buffer to the total wattage to ensure the power supply is not overworked.

Step 2: Choose a Power Supply

Select a power supply that meets or exceeds the calculated requirement. Consider the installation location and whether you need a waterproof or indoor-rated power supply.

Step 3: Connect the Power Supply

Connect the power supply to your COB LED strip, ensuring all connections are secure and correctly polarized. Test the setup to ensure everything works as expected before finalizing the installation.

For more information, please check How To Choose the Right LED Power Supply.

Dimming and Controlling COB LED Strips

Can You Dim COB LED Strip?

Yes, you can dim a COB LED strip using a compatible LED dimmer switch or a dimmable power supply. Ensure compatibility with your strip’s voltage and current requirements.

Adding dimming and control capabilities to your COB LED strips allows for flexibility in lighting design and ambiance. Here’s how to get started:

Step 1: Select a Compatible Dimmer

Choose a dimmer that is compatible with your COB LED strip’s voltage and power requirements. For smart lighting setups, ensure the controller is compatible with your home automation system.

Step 2: Connect the Dimmer

Integrate the dimmer or controller between the power supply and the COB LED strip. Follow the manufacturer’s instructions for wiring and setup.

Step 3: Test the Setup

Once everything is connected, test the dimming and control functions to ensure they work as expected. Adjust settings according to your preferences and enjoy the enhanced ambiance and functionality of your COB LED lighting.

Longevity and Quality Assessment

How Long Do COB LED Strip Lights Last?

How Long Do COB LED Strip Lights Last? COB LED strip lights are renowned for their longevity, with many strips rated for up to 50,000 hours of use. This translates to years of reliable lighting, assuming several hours of operation each day. The actual lifespan of a COB LED strip can vary based on factors such as the quality of the strip, the operating environment, and the frequency of use. To maximize the lifespan of your COB LED strips, ensure they are installed in a way that allows for adequate heat dissipation and avoid exposing them to excessive moisture or mechanical stress.

Do COB LED Strips Get Hot?

Yes, COB LED strips can get warm during operation, but they generally produce less heat compared to traditional lighting. If you are concerned about excess heat, you can attach the COB LED strip to an aluminum profile to help with heat dissipation.

Do COB LED Strips Use a Lot of Electricity?

No, COB LED strips are very energy-efficient compared to other lighting options.

Are COB LED Strips Brighter?

Compared to SMD LED strips, COB LED strips are slightly less bright at the same power level. For instance, COB LED strips with a CRI90 typically offer 110-120 LM/W, whereas high-efficiency SMD LED strips can reach up to 150-160 LM/W.

Do COB LED Strips Need a Diffuser?

No, COB LED strips do not need a diffuser. They provide very uniform lighting, which is one of their main advantages.

Can I Cut COB LED Strip Anywhere?

For regular COB LED strips, you can only cut at the designated cutting points. However, we offer a special series called the Free Cutting COB LED Strip Series, which can be cut anywhere.

Why Are COB LED Strips Yellow?

The yellow color is due to the phosphor coating. If you don’t like this yellow appearance, you can choose our COB Plus Series, which has a silicone covering that hides the phosphor, providing a more attractive look.

Can I Bend COB LED Strip?

Yes, you can bend COB LED strips to fit different spaces and shapes. COB lights are very flexible since their diodes are smaller and placed closer together, allowing them to curve into tight areas or fit around corners.

Can You Bend a COB LED Strip 90 Degrees?

If bending vertically, yes. However, for horizontal bends, use an L-shaped LED strip connector.

How to Judge the Quality of COB Light Strips?

When assessing the quality of COB LED strips, consider the following factors:

Step 1: Check the Manufacturer and Brand Reputation

Look for COB LED strips from reputable manufacturers and brands with positive reviews and testimonials. Established companies often adhere to higher quality standards and offer better customer support.

Step 2: Inspect the Materials and Build Quality

Examine the materials used in the COB LED strip, including the flexibility of the PCB, the uniformity of the LED placement, and the quality of the adhesive backing. High-quality strips will have a sturdy construction and even, consistent lighting without visible gaps or irregularities.

Step 3: Evaluate the Specifications

Review the technical specifications of the COB LED strip, including the color temperature, CRI, luminous efficacy (lumens per watt), and rated lifespan. Higher numbers in these areas generally indicate a better-quality strip. Additionally, look for certifications or ratings that indicate testing and compliance with industry standards, such as UL listing or IP ratings for moisture resistance.

By carefully evaluating these factors, you can select high-quality COB LED strips that offer superior performance, reliability, and longevity for your lighting projects.

Comparisons and Alternatives

COB LED Strips VS. SMD LED Strips

In the realm of LED lighting, COB (Chip On Board) and SMD (Surface Mounted Device) LED strips are leading solutions, each offering distinct features suited to various lighting needs. COB LED strips are celebrated for their seamless and uniform illumination that eliminates visible dots and hotspots, providing a smooth light output. In contrast, SMD LED strips are versatile in terms of brightness and color options, catering to dynamic and customizable lighting environments. Understanding the core differences between these two technologies can significantly influence the selection process for your lighting project, ensuring you opt for the type that aligns with your specific requirements.

Here is a refined comparison to illustrate the primary differences:

| Feature | COB LED Strips | SMD LED Strips |

| Brightness and Uniformity | Deliver uniform light across the strip without visible dots or hotspots, ideal for creating a smooth lighting experience. | Capable of high brightness but may display visible LED dots, affecting the uniformity of the light. |

| Flexibility | Offer enhanced flexibility, allowing for tighter bends and curves without compromising the integrity of the light source. | Flexible, but with limitations compared to COB LEDs, especially around tight bends. |

| Efficiency and Heat Dissipation | Generally more efficient with superior heat dissipation, contributing to a longer lifespan and consistent performance. | Efficient but may not manage heat as effectively as COB LEDs, which can influence longevity. |

| Customization and Color Options | Traditionally focused on single-color and tunable white options, though advancements are being made to include a broader color spectrum. | Provide a wide array of color options, including RGB, RGBW, and tunable white, suitable for customizable and dynamic lighting applications. |

| Application Suitability | Best suited for applications where a continuous, uniform light output is essential, such as accent lighting or areas where strips are directly visible. | Ideal for projects requiring specific color settings, high brightness, or where individual light points can be diffused or hidden. |

This comparative overview aims to clarify the key distinctions between COB and SMD LED strips, aiding in the decision-making process for your lighting projects. Whether you prioritize uniformity and sleekness or versatility and dynamic color options, understanding these differences ensures that your chosen LED strip perfectly matches your lighting needs.

COB LED Strips VS. CSP LED Strips

In the realm of LED lighting technology, COB (Chip on Board) and CSP (Chip Scale Package) LED strips represent two innovative approaches to illumination. While both offer high-quality, uniform lighting, they differ in design, integration, and performance characteristics. COB LED strips are known for their seamless light output and superior heat management, thanks to a larger substrate that enhances durability. On the other hand, CSP LED strips stand out for their compactness and the ability to place chips closer together, which can lead to a higher luminous intensity within a smaller area. Below is a comparative analysis to help highlight the key differences between these two types of LED strips.

| Feature | COB LED Strips | CSP LED Strips |

| Size and Integration | Larger substrate allows for a seamless line of light without visible LEDs. | More compact with closer chip placement, offering high luminous intensity in a smaller footprint. |

| Light Quality and Uniformity | Excel at creating a uniform light output across the strip, ideal for applications where a continuous light source is needed. | Provide high-quality, uniform light output, but may not achieve the same seamless effect as COB strips. |

| Durability and Heat Management | Generally offer better heat dissipation due to the larger substrate area, enhancing the longevity and reliability of the strip. | Compact size may limit heat dissipation capabilities compared to COB strips, potentially affecting durability. |

Understanding these distinctions is crucial for selecting the right LED strip for your project, ensuring that you achieve the desired lighting effect, efficiency, and lifespan. Whether you prioritize the compactness and intensity of CSP LED strips or the seamless illumination and durability of COB strips, both technologies bring unique advantages to the table. For more information, please check The Ultimate Guide To CSP LED Strip and CSP LED Strip VS COB LED Strip.

Is There an Alternative to COB LED Strips?

For those seeking alternatives to COB LED strips, several options are available, each with its unique characteristics:

- Traditional SMD LED Strips: Offer flexibility in color and brightness options, suitable for a variety of applications.

- CSP LED Strips: Provide a compact and efficient lighting solution with high luminous intensity.

- EL (Electroluminescent) Wire or Tape: Offers a unique, neon-like glow for decorative applications but with lower brightness and efficiency compared to LED solutions.

- Fiber Optic Lighting: Delivers distinctive lighting effects and is ideal for accent lighting, though it requires a light source and is less versatile than LED strips.

Each of these alternatives has its place in specific applications, depending on the desired lighting effect, efficiency, and installation considerations.

COB LED Strip Sample Book

A COB LED Strip Sample Book is an essential tool for designers, architects, and lighting professionals who wish to explore the variety and capabilities of COB LED strips firsthand. This comprehensive collection showcases a range of COB LED strips, including various color temperatures, luminosities, and special features such as Tunable White and Dim to Warm options. Each sample is accompanied by detailed specifications and application suggestions, providing users with a tangible reference to aid in the selection process. The Sample Book is designed to demonstrate the superior quality, flexibility, and light uniformity of COB LED strips, making it easier for professionals to make informed decisions based on their project needs. Additionally, it serves as a valuable resource for understanding the potential of COB LED technology in creating customized lighting solutions for any environment, from residential to commercial spaces.

Solderless COB LED Strip Connector

Solderless COB LED Strip Connectors streamline the installation of COB LED strips by eliminating the need for soldering. These user-friendly connectors allow for quick, secure, and reliable connections, simplifying the setup process. Designed to fit various strip widths, they come in multiple shapes for flexible configurations. Ideal for both DIY projects and professional applications, solderless connectors make creating custom lighting solutions effortless and efficient.

Troubleshooting COB LED Strip Lights

COB (Chip on Board) LED strips are popular for their uniform light output and high efficiency. However, like any electronic device, they can encounter issues. Here are common problems and their solutions:

LED Strip Does Not Light Up

- Check Power Supply Compatibility: Ensure the power supply’s voltage and current ratings match the LED strip’s requirements. For instance, a 12V power supply will not work with a 24V LED strip.

- Verify Power Supply Functionality: Use a multimeter to check the voltage output of the power supply. If the voltage is lower than expected, the power supply may be faulty.

- Inspect Connections: Ensure all connectors and wires are securely in place. Loose connections can prevent the strip from lighting up.

- Isolate Accessories: Remove any dimmers or controllers to see if the strip lights up without them. This can help identify if the issue lies with these accessories.

Uneven Lighting

- Quality of LED Strip: Low-quality LED strips may have inconsistencies in brightness. Ensure you are using high-quality, certified LED strips to avoid this issue.

- Power Supply Adequacy: An underpowered supply can cause uneven lighting. Make sure the power supply can handle the total wattage of the LED strip.

- Placement: Uneven placement on surfaces can cause inconsistent light output. Ensure the strip is evenly placed and test the layout before permanent installation.

Flickering Lights

- Power Supply Issues: Flickering can occur if the power supply is not providing enough power. Ensure the power supply meets the LED strip’s requirements and consider following the 80/30 Rule (using only 80% of the power supply’s capacity).

- Faulty LEDs: If specific sections flicker, the LEDs might be faulty. Replace the faulty section or contact the manufacturer if the issue persists.

Dim Lights

- Voltage Drop: Measure the input voltage at the LED strip connection. If it is significantly lower than the rated voltage, check for loose or corroded connections and ensure the power supply is adequate. For more information, please check What is LED strip voltage drop?

- LED Degradation: Over time, LEDs can lose brightness. If the input voltage is correct but the strip is still dim, the LEDs may be failing, and replacing the strip might be necessary.

Specific Case: Multiple Strips with Power Issues

If you have multiple strips connected and one strip is not receiving enough power or flickers, consider the following:

- Voltage Drop Due to Cable Length: Shorten the cables to reduce voltage drop. Ensure the wire gauge is appropriate for the current load.

- Power Supply Capacity: Verify that the power supply can handle the total wattage of all connected strips. If necessary, upgrade to a higher current output power supply.

- Connection Configuration: Ensure the strips are connected correctly. Incorrect wiring can lead to power distribution issues.

By following these troubleshooting steps, you can address common issues with COB LED strips effectively. If problems persist, contacting the manufacturer or seeking professional assistance is recommended.

For more information, you can check Troubleshooting LED Strip Problems.

FAQs

The LED chip is mounted directly on the FPCB and covered with a layer of phosphor acting as a diffusion on the chip surface. Due to the small chip size, the chip density of COB LED strips is high and can exceed 500 chips per meter.

For the regular power COB LED strip, it will not be very hot, the temperature is around 40 degrees Celsius.

Around 50000 hours.

No, COB is usually not as bright as SMD LED strips. CRI90 COB LED strips generally have a luminous efficacy of 100LM/W, while SMD LED strips can have a luminous efficacy of up to 150LM/W.

Yes, you can cut the COB LED strip at the location of the cut mark.

No, the light efficiency of COB LED strips is not as good as SMD LED strips.

CRI90 COB LED strips generally have a luminous efficacy of 100LM/W, while SMD LED strips can have a luminous efficacy of up to 150LM/W.

Yes, COB LED strips can be used outdoors if they are specifically rated for outdoor use. Look for strips with an appropriate IP (Ingress Protection) rating that indicates resistance to dust and water, such as IP65 or higher.

COB LED strips are powered by a compatible power supply, also known as a driver. The power supply’s voltage must match the strip’s voltage requirement, and its wattage should be sufficient to handle the total power consumption of the strip, with a little extra capacity for safety.

Yes, many COB LED strips are dimmable, but you’ll need a compatible dimmer switch or controller that matches the strip’s voltage and dimming method (e.g., PWM, 0-10V, DALI).

The maximum continuous run length of a COB LED strip depends on its voltage and power consumption. Higher voltage strips (e.g., 24V) can typically be run longer than lower voltage strips (e.g., 12V) before experiencing voltage drop. Refer to the manufacturer’s specifications for recommended maximum lengths.

Initially, COB LED strips may be more expensive due to their advanced technology and manufacturing process. However, prices are becoming more competitive, and the cost must be weighed against the benefits of improved light quality, uniformity, and efficiency.

COB LED strips can be cut at designated points and connected with flexible connectors to navigate tight corners. Alternatively, bending the strip carefully at the corner or using corner connectors can achieve a seamless installation.

Repairing COB LED strips can be challenging due to their construction. If a section of the strip fails, it’s often easier to replace that section rather than attempting a repair. Always consult the manufacturer’s guidelines or seek professional assistance.

While COB LED strips generally have better heat management than SMD strips, installing them on a heat sink or aluminum profile can enhance their longevity by improving heat dissipation, especially in high-power applications.

Multiple COB LED strips can be connected end-to-end with solderless connectors or by soldering wires between the strips, depending on the installation requirements. Ensure that the power supply can handle the total load.

Yes, COB LED strips can be integrated into smart home systems or controlled via smartphone apps with the appropriate controllers and connectivity options, such as Wi-Fi or Bluetooth.

Conclusion

COB LED strips represent a significant advancement in LED lighting, offering superior light quality, uniformity, and efficiency. Whether for residential, commercial, or creative applications, COB LED technology provides a versatile and effective lighting solution.

By considering factors such as color temperature, brightness, and installation requirements, you can choose the right COB LED strip for your needs, enhancing the aesthetics and functionality of any space. As technology evolves, COB LED strips continue to offer innovative possibilities for lighting design, making them a preferred choice for lighting professionals and enthusiasts alike.