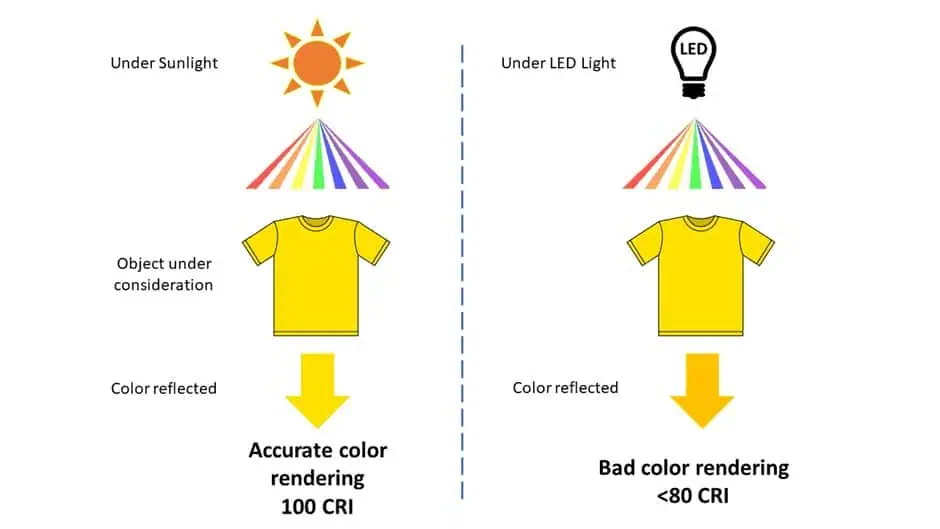

The color of an object looks very different under lights with varying CRI ratings. And a high CRI fixture gives a more realistic visual by closely mimicking the sunlight. In contrast, low CRI results in faded color that’s far apart from the actual color of an object.

Therefore, to get an accurate visual of any object, you must consider the light’s CRI values.

What Is CRI?

Color Rendering Index or CRI compares the color accuracy of an object under artificial lighting to that of natural sunlight. If the object under the light source looks similar to what you see in daylight, it has a high CRI. In contrast, if there’s a visible difference in color appearance, this means the light source is of low CRI. This way, by considering CRI values, you can identify the quality of light in terms of providing color accuracy.

Basics Of CRI: How It Works?

a. Scale & Range Of CRI

The CRI is measured on a 0 to 100 scale. Higher CRI means better color accuracy. Lighting with CRI below 80 is considered poor. In contrast, fixtures with CRI>90 are considered excellent.

| CRI | Quality |

| 0 | Low |

| 10 | |

| 20 | |

| 30 | |

| 40 | |

| 50 | |

| 60 | Acceptable |

| 70 | |

| 80 | Good |

| 90 | Excellent |

| 100 |

b. Measures Quality of Artificial White Light Sources

CRI measures the color accuracy of artificial white lights like LED and fluorescent light to natural daylight. Thus, by checking the CRI value, you can get an idea of the fixture’s ability to mimic sunlight.

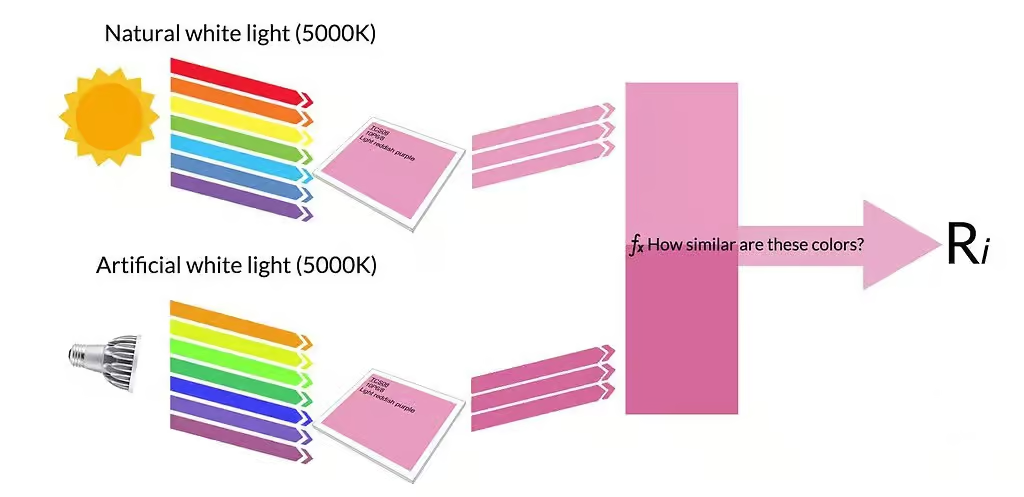

c. CRI Measures and Compares the Reflected Color of an Object Under Artificial Lighting

The sunlight is white in color, but it is a combination of all the colors of the visible light spectrum. So, when the sunray falls on an object, the color of that object reflects to your eyes. The rest of the colors are being absorbed by the object. That is how you can see an object.

When you are using an LED light or other bulbs, it tends to emit a light spectrum similar to sunlight. Close the emitted light spectrum matches the sunlight, more accurate color perception the light provides.

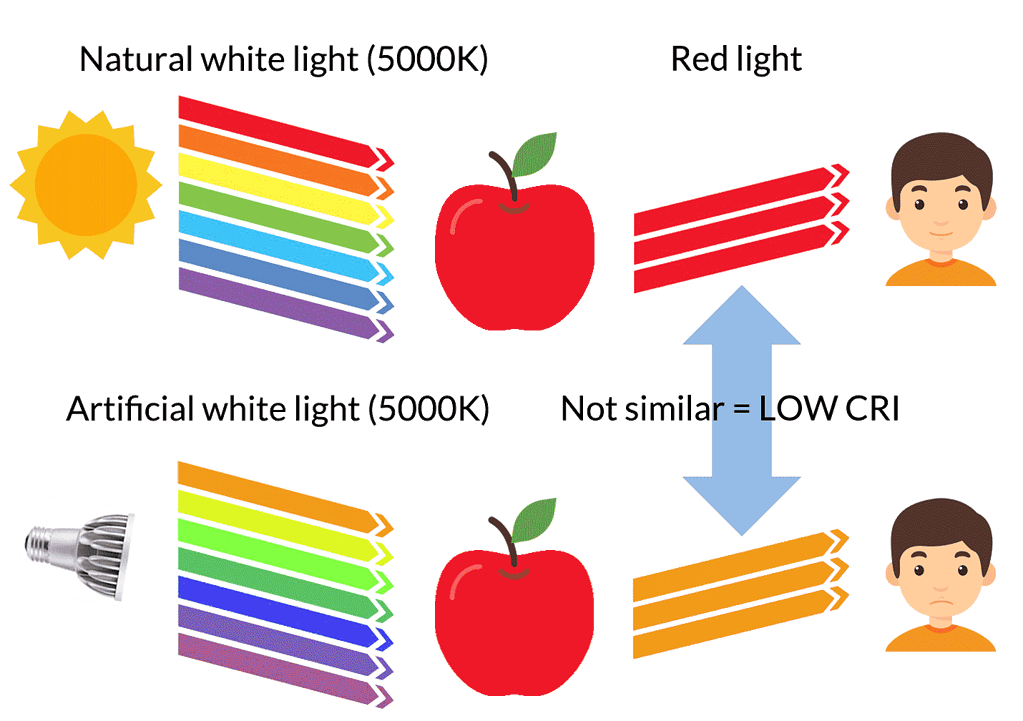

For example, take two apples and place one under sunlight (5000 CCT) and another under a 5000 CCT LED light. Though both have the same CCT, the apple in natural light looks more red than the other. This happens because LEDs don’t emit the same light spectrum as sunlight. Thus, the color under this light appears different due to having low CRI.

d. You Can’t Determine CRI Without Comparing The Color Output

As you have seen above, the same light color can have varying light spectrums. Thus, by observing the light color, you can’t find out its CRI. Instead, you need to direct the light to varying objects and check the difference between them and sunlight.

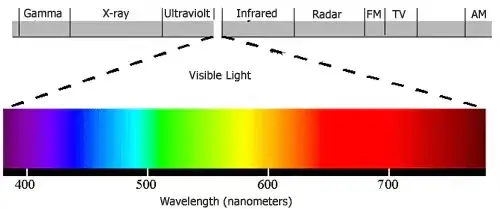

Spectral Power Distribution

If you look at the spectral distribution graham, you can see how light wavelength matters for color visibility. The wavelength of the visible part of the electromagnetic spectrum ranges from 400 to 750 nanometers. This is what we call the full visible spectrum. So, a light source with a full visible spectrum will have CRI 100. That is, you will get accurate color visibility.

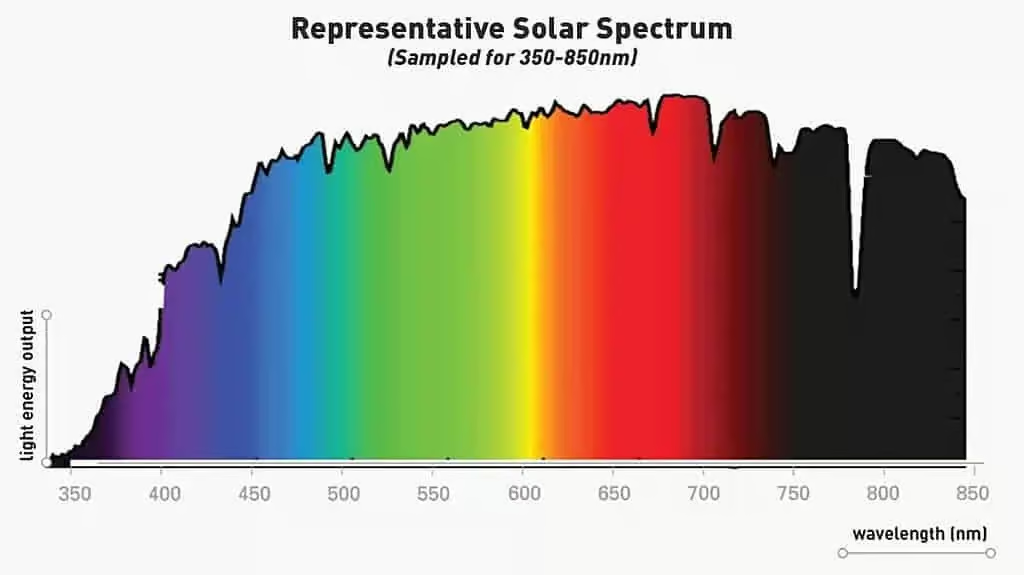

Below, you will see a typical spectral power distribution graph for daylight.

Notice the strong presence (high relative power) of ALL wavelengths (or the “full-color spectrum”). Daylight provides the highest level of color rendering across the spectrum.

Compare the daylight spectral power distribution with that of an LED light.

The graph we used here is of warm tone, having a CCT of 2700K and a CRI of 82. Though its CCT is far lower than that of daylight (5000K), its color rendering ability is not bad. However, it’s worse when you compare it to natural daylight.

The most obvious difference is the generally lower level of relative power compared to daylight – except for a few spikes. Again, all wavelengths (the full spectrum) are present, but only certain wavelengths (the spikes) are strongly present. These spikes indicate which parts of the color spectrum will be emphasized in the rendering of color for objects illuminated by the light source.

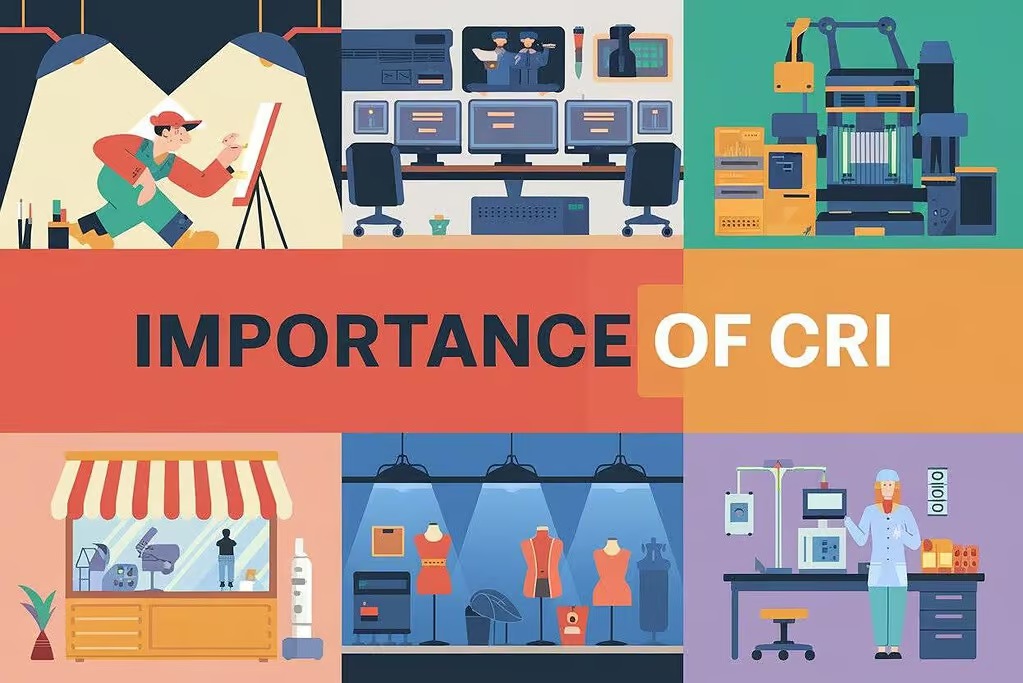

Importance of CRI

1. Accurate Color Representation

How an object looks in artificial lighting depends heavily on CRI. This is why high CRI lighting is essential for applications where color accuracy is mandatory. For example- the lighting in art galleries, photography, TV, etc., should have a higher color rendering index. If the light used is of poor CRI, you won’t get the expected outcome.

For instance, painting under low CRI lighting makes painters confused in choosing the right color. Once his painting is set outdoors in natural lighting, it will look so different than he actually expected. This is why high CRI is mandatory to ensure color accuracy.

2. Visual Comfort and Productivity

Proper color accuracy provides you with a comfortable and productive environment. With higher CRI, the employees and workers will have a far more pleasant environment. This reduces stress, headaches, and eye strain and improves the overall mood of the employee. Thus, the employees can work with ease and increase their productivity.

3. Industrial Applications

In industrial-level applications like textile and printing, maintaining color accuracy is mandatory. If there is any difference in color, you won’t get the expected output of the final product. That is why CRI is also an essential consideration at an industrial level.

4. Retail Stores

If you have low CRI lighting in your retail store, the customer may purchase an orange dress but find it red once she gets out of the store. This will badly hamper your brand reputation. That is why you must install high CRI bulbs in your shop.

5. Medical and Scientific Applications

CRI provides you with accurate color perception when reading the diagnosis reports, detecting skin tones, and identifying substances correctly.

How To Measure CRI?

1- Measuring CRI Of Daylight

You need to follow the industry-standard method of CIE to measure the CRI of any light source. Here, a black body radiator with a perfect CRI score of 100 is taken as a reference sample. You need to compare the test source’s color rendering with this sample. To calculate the general CRI rating, you need to select 15 primary reference samples considering the color temperature of the tested light.

CIE (1999) numerically organized these reference samples in The Color Checker chart. This starts with TCS01, referred to as ‘Light Grayish Red,’ and ends with TCS15, referred to as ‘Asian skin.’ The closer the tested source matches the reference sample, the higher the CRI rating it will have.

We compare the reflected colors and formulaically determine each color swatch’s “R” score.

The R-value for a particular color indicates the ability of a light source to faithfully render that particular color. Therefore, the CRI formula takes an average of the R values to characterize the overall color rendering capability of a light source.

- Ra is the average value of R1 through R8.

- AvgR is the average value of R1 through R15.

- Special value: R9

In general, in CRI calculation, Ra is the average of R1–R8. Here, the values from R9 to R15 are not counted. However, for applications requiring a high color rendering index, R9 is a crucial consideration. It determines the light source’s ability to reflect the red color accurately. That is, it rates the tested light source based on its ability to go closer to TCS 09 of the ColorChecker chart.

Therefore, considering R9 is very important in getting accurate color perception in applications where red is a crucial color. For instance, the color red is important for applications like film, medicine, and art lighting.

However, in some cases, the color red remains in a hidden form, such as our skin. Though our skin looks whitish or yellowish, the tone of our skin is impacted by the red blood underneath. So, if the R9 value is not good enough, the skin tone under this light will be pale or even greenish in your eyes or cameras.

2- Measuring CRI Of Non-Day Light

For simplicity, we’ve assumed a 5000K color temperature for our examples above and compared it to a 5000K natural daylight spectrum for CRI calculations.

But what if we have a 3000K LED lamp and want to measure its CRI?

The CRI standard dictates that color temperatures of 5000K and greater use a daylight spectrum, but for color temperatures of less than 5000K, use the Planckian radiation spectrum. Planckian radiation is essentially any light source that creates light by generating heat. This includes incandescent and halogen light sources.

So while measuring the CRI of a 3000K LED lamp, you need to judge it against a “natural” light source having the same spectrum as a 3000K halogen spotlight.

(That’s right – despite the awful energy efficiency of halogen and incandescent bulbs, they produce a full, natural and excellent light spectrum).

3- Limitations In Measuring CRI

Limited Sample Colors

CRI is measured based on only 8 sample colors; all colors of the real world are not included in it. So, accurate color accuracy is not ensured.

Equal Weighting

The colors used as CRI samples have the same weight. So, in some applications, you can differentiate some colors.

Color Temperature Dependency

CRI is highly dependent on color temperature. Its value drops as the CCT goes away from the natural daylight CCT (5000K to 5500K).

Lack Of Saturation Information

CRI doesn’t measure the saturation of light color. So, this matrix is not applicable where you need to measure saturation and color vibrancy.

Key Factors Influencing the CRI Scores

Light Source

The light source has a greater influence on CRI. The value of CRI varies for different lighting technologies. The chart below will give you a clear idea of how the type of light source impacts the CRI value:

| CRI For Different Light Technology | ||

| Type of Light | CCT | CRI Ratings |

| LEDs | 2700–5000K | 80 to 100 |

| Incandescent | 3200K | 100 |

| Clear Mercury Vapor | 6410K | 17 |

| “White” SON | 2700K | 95 |

| Tri-phospher Warm-White Fluorescents | 2940K | 73 |

| High-Pressure Sodium Lighting | 4080K | 89 |

| Quartz Metal Halide | 4200K | 85 |

| High Pressure Sodium Lighting | 2100K | 25 |

| Clear Mercury-Vapor Lamps | 6410K | 17 |

| Low-Pressure Sodium Lighting | 1800K | -44 |

Material of the Object

The object’s ability to absorb, reflect, and transmit light affects the CRI values. For this, CRI can vary depending on the object’s material, texture, and reflective properties. Therefore, to get the desired CRI rating, you must understand the interaction between materials and light.

Distance and Angle

The color appearance of an object can vary with the distance and angle at which the light falls on it. The light’s intensity decreases as its distance from the object increases. Again, light can also create shading on the object for a certain angular direction. All these impacts color perception of the object. Therefore, you must consider the placement and orientation of lighting fixtures to achieve optimal CRI.

Specific Color & Quality of Illuminated Objects

CRI is based on 15 sample colors. So, some objects whose color doesn’t fall under this specific sample color won’t show an accurate CRI rating.

Lighting Environment

The background and surrounding color also impact the color perception of objects. This impacts CRI rating. For example – an object will appear different for a high-contrast and low-contrast background.

Impact of CRI on Human Perception

Humans heavily depend on color perception in day-to-day life. For instance, you can identify ripe fruits via their color. In this case, high CRI helps the eyes to get the correct perception of the color.

Again, as humans age, their eyesight and color-distinguishing capability reduce. So, a high CRI light helps old people with poor eyesight to identify colors.

How To Choose the Right CRI For Different Applications?: A Guide

a. Location & Purpose Of Lighting

The requirement of CRI varies for different applications. High-CRI-rated bulbs are usually more expensive than low-rated ones. So why waste your money on high CRI where it isn’t mandatory?

The below chart will help you find the right CRI ratings for your application:

| Location | Recommended CRI | Description |

| Living and Bedrooms | 80 or above | This will bring accurate color perception of the decoration and complement the warm and cozy ambiance of the bedroom. |

| Bathrooms and Dressing Rooms | 90 or above | Higher CRI will give the correct color perception that is essential for grooming, makeup and dress selection. |

| Kitchens | 85 or above | This CRI rating ensures accurate color representation of the food, vegetables, spices, and other ingredients to aid you in cooking. |

| Home Offices or Study | 85 or above | It will reduce eye strain and provide clear visibility while studying. |

| Art Studios or Craft Rooms | 95 or above | This ensures the true color of the artworks so they look the same in daylight. |

| Retail Lighting | 90 or above CRI | Higher CRI will ensure the accurate color of the product, helping the customer make purchasing decisions with confidence. |

| Photography and Videography | 95 or above | For capturing the accurate color of the person and the surrounding objects |

| Medical and Dental Facilities | 90 or above CRI | Diagnose the condition of the patient, for example, color of eye, skin, blemishes, injuries, etc. |

| Industrial and Manufacturing | 80+ for general manufacturing | For identifying errors and defects in the product and taking necessary steps to get the expected final output. |

| 90 or above for quality check |

b. Light Technology

The CRI ratings also depend on the lighting technology. Traditional bulbs like incandescent have CRI 100. So, using these bulbs, you will always get 100% color accuracy, but these are not energy efficient. However, LED lighting offers you a variety of CRI and is highly energy efficient. So, choose one that fits your needs.

c. Color Temperature

The fixture with a color temperature closer to natural daylight gives a higher CRI. So, you will get better color accuracy for CCT ranging from 5000K to 5500K. In contrast, lower CCT bulbs with warm tones or high CCT bulbs with cool tones give lower CRI compared to natural daylight. However, you can go for tunable white lighting to adjust the color temperature and CRI to meet your needs.

d. Manufacturer Specifications

The manufacturer’s specification includes the information about the light’s CRI ratings. So, by going through the packaging or specifications, you can pick the ideal one. However, you must also check the test reports and certifications to ensure correct CRI calculation.

e. Regulatory Standards For CRI

Different international lighting standards have specific CRI requirements. I’ve pointed out the most essential ones:

- Energy Star

Energy Star is a U.S. government-backed seal mark to ensure the energy efficiency of the light fixtures. U.S. Department of Energy (DOE) and U.S. The Environmental Protection Agency (EPA) is in charge of this standard. To achieve an Energy Star marking, you must have the following CRI ratings:

| Type Of Lightings | Required CRI for Energy Star Standard |

| CFL Lights | At least CRI 80 |

| Incandescent | CRI of 100 |

| Linear Fluorescent Tubes | CRI around 75 |

| LED Lights | CRI ≥ 80 |

- European Union

The European Union (EU) regulates lighting standards for using and exporting lighting in Europe. The Ecodesign Directive of this organization sets the CRI values to ensure product quality. According to the EU, lights must have at least CRI ≥ 80.

- International Commission on Illumination (CIE)

CIE is an internationally recognized organization dealing with different lighting aspects. It publishes different guidance for maintaining color quality and CRI ratings.

- International Electrotechnical Commission (IEC)

It is an international standard that deals with electrical and electronic technologies. It includes the methods of calculating the CRI for different types of lighting technology. FRor instance:

- IEC 60081 defines how to measure the CRI of fluorescent lighting

- IEC 60901 is similar to IEC 60081, dealing with CRI of fluorescent lighting

- IEC 62922 explains the methodology of measuring CRI in LED technology

f. Cost and Budget

Lightings with high CRI are expensive. So, you must find an appropriate CRI rating for your lighting that fits your budget. However, the price of the lights with the same CRI can vary from brand to brand.

Why Buy High CRI Lights?

High CRI means better color accuracy. By buying lights with a high CRI >95, you will get a realistic color perception of the objects. It also offers the following benefits:

- Realistic color appearance

- Reduces eye strain & offers visual comfort

- Minimizes the risk of error caused due to wrong color perception

- Meets international lighting standards

- Enhances the beauty and visual appeal of products

Drawbacks of Using Low CRI Lights

Poor Color Accuracy

Due to using low CRI lights, you won’t get to see the actual color of an object. It fades the color and makes it look unnatural. This can greatly hamper retail businesses and industries like fashion apparel, textiles, etc., where color accuracy is mandatory.

Strain and Discomfort

Hash lighting with low CRI rating leads to eye strain and headache. Thus, you can’t focus on work. This way it can reduce your productivity and hamper the task.

Reduced Quality of Work

In low CRI lighting, the color of an object looks very different from its actual color. Therefore, using a low CRI light in applications like fashion apparel, textiles, etc., will mess up your task. For instance, while painting, a wrong color mixture will damage the final output. This way, the quality of the work is affected by low CRI lights.

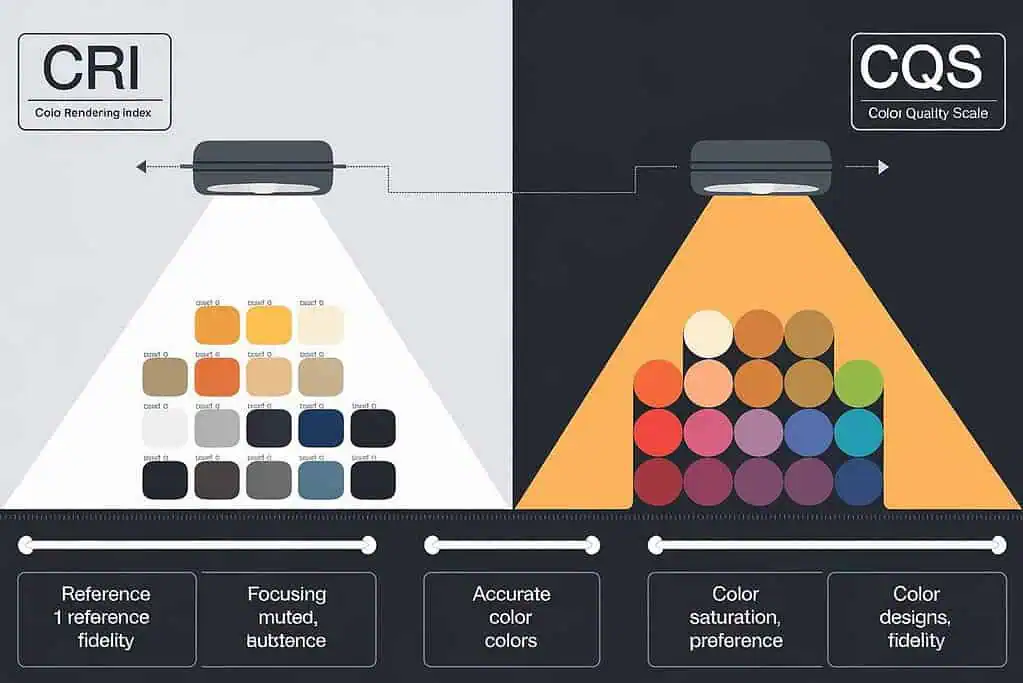

CRI Vs. Other Color Quality Related Lighting Metrics

CRI VS CQS

Similar to CRI, the Color Quality Scale (CQS) also measures the color rendering capabilities of light sources. However, CQS is a more recent metric that reduces the limitation of CRI. Where CRI focuses only on color fidelity, CQS considers other aspects of color rendering, including color saturation and color preference.

Again, in CRI, only 8 reference samples were used to evaluate light. Meanwhile, CQS uses 15 color-evaluating samples. Therefore, CQS gives a more in-depth view of the color rendering quality of light.

| Aspect | Color Rendering Index (CRI) | Color Quality Scale (CQS) |

| Primary Focus | Color Fidelity | Color Quality |

| Color Accuracy | Measures color accuracy | Considers color accuracy but also saturation and preference. |

| No. of Color Evaluating Samples | 8 | 15 |

| Saturation | Not Considered | Considered |

| Color Preference | Not Considered | Considered |

| Application Focus | General lighting scenarios | More specialized or aesthetic-focused lighting scenarios |

CRI VS TM-30

Compared to 8 color evaluating samples of CRI, TM-30 uses 99 referral samples! Unlike CRI, it not only focuses on the Fidelity Index (Rf) but also includes the Gamut Index (Rg). Thus, using TM-30 as a color rendering matrix, you will get to know the shifts in saturation, too. This makes this matrix suitable for applications requiring higher color accuracy.

| Criteria | Color Rendering Index (CRI) | TM-30 |

| Primary Focus | Color Fidelity | Color Fidelity and Gamut |

| Color Accuracy | Measures color accuracy | Provides detailed color fidelity metrics |

| No. of Color Evaluating Samples | 8 | 99 |

| Saturation | Not Considered | Considered and analyzed |

| Hue Change | Not Considered | Considered and analyzed |

| Information Depth | Single value representation | Multi-metric representation including fidelity index (Rf) and gamut index (Rg) |

| Application Focus | General lighting scenarios | Specialized or high-accuracy color rendering scenarios |

CRI Vs GAI

Gamut Area Index (GAI) compliments CRI by focusing on color intensity and vibrancy. CRI is crucial for applications that need color accuracy. On the other hand, GAI is considered for applications that require vibrancy and more saturation.

| Criteria | Color Rendering Index (CRI) | Gamut Area Index (GAI) |

| Primary Focus | Color accuracy | Color saturation or vibrancy |

| Saturation | Not Considered | Considered and analyzed |

| Hue Change | Not Considered | Considered and analyzed |

| Application Focus | Applications requiring accurate color reproduction, such as art galleries, medical settings, and design work. | Settings requiring vibrant colors, like retail displays, horticulture, and entertainment lighting. |

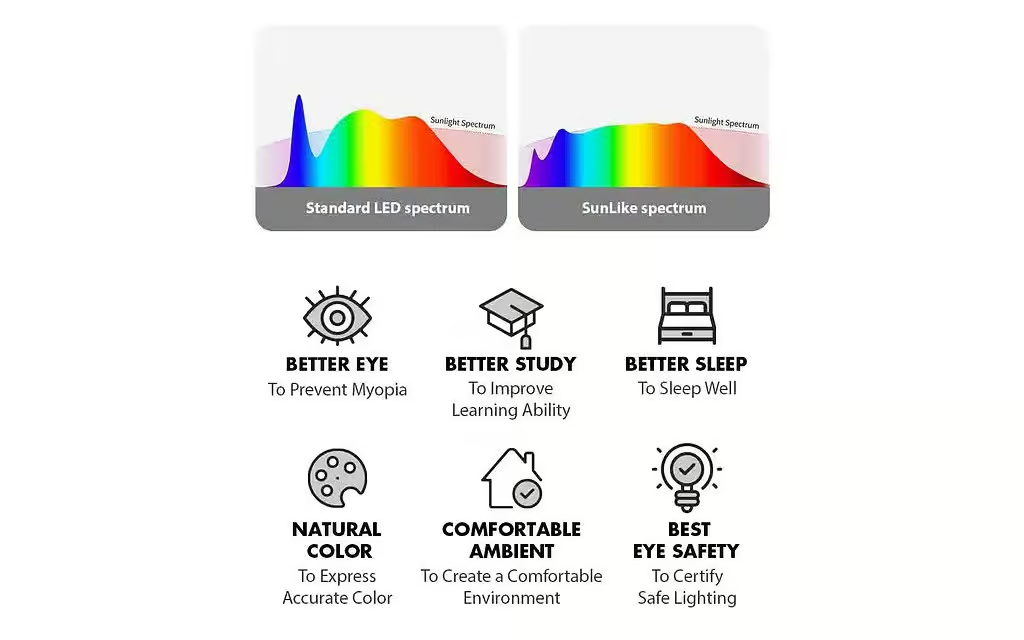

Full Spectrum Lighting and SunLike Natural Spectrum LED Technology

Full Spectrum Lighting has all wavelengths falling under the visible light spectrum. It thus mimics the sunlight and offers higher CRI ratings. However, Seoul Semiconductor has taken full spectrum lighting to the next level with its SunLike Natural Spectrum LED Technology. This technology was co-developed through a combination of Seoul Semiconductor’s optical semiconductor technology and Toshiba Materials’ TRI-R technology.

Lights designed with this technology mimic the sunlight very closely, offering accurate color accuracy just as you see in natural daylight. Thus, SunLike LEDs ensure a high color rendering index (CRI) of 98+.

Future Trends in Color Rendering

1. Growing Popularity Of Advanced Metrics

CRI has some limitations that matrices like TM-30 & CQS easily cover. So, to evaluate color rendering, these units are going to be more popular than the CRI.

2. Human-Centric Lighting

Human-centric lighting is gaining popularity as it is designed to provide comfortable lighting. So, you will find a higher CRI rating in all types of human-centric light to ensure visual comfort.

3. Smart Lighting Solutions

Smart lights with advanced features facilitate adjustable CCT options. However, such customization options will soon come for CRI, too.

FAQs

For indoor lighting, the general baseline is CRI 80. However, based on applications that require high color accuracy, CRI>90 is a must.

The higher the CRI, the better the color accuracy. The best CRI for LED lights ranges from CRI95 to CRI100.

CRI determines the accuracy of color perception of an object under an artificial light source. So, for low CRI light, you won’t see the actual color of the object. The light source must have a higher CRI rating to see the accurate color.

High CRI ratings like 98 or 100 have a full visible light spectrum. Therefore, using high CRI lighting as grow light mimics sunlight, and plants get essential wavelengths for growth. However, it is not an essential factor in choosing to grow lights.

For outdoors, the most common CRI rating ranges from 70 to 80. This offers a balance of visibility and energy efficiency for street lights and common outdoor usage.

The sunlight has the highest CRI score, which is CRI100. So, any light fixture that has CRI100 will mimic the color perception of sunlight.

Traditional fixtures like incandescent and fluorescent have the best or highest CRI=100. However, LED lights are also available with a CRI100 rating.

CRI 80 or above is a good CRI rating for LED lights. However, for excellent outcomes consider fixtures with CRI>95 or higher.

Wrapping Up

To sum up, considering high CRI is essential to ensure proper color perception of your surroundings. Low CRI lights will not only affect the color appearance but also cause discomfort and hamper work productivity. Therefore, you must consider your application needs and pick the right CRI following the above guidelines.

However, to ensure you are purchasing quality light with an honest CRI rating, LEDYi is your most trusted solution. All our full spectrum LED strip lights are of high CRI, Ra>97. As we are a certified company, you need not worry about its accuracy. So, why wait anymore? Place your order right away!