Studying the internal schematic of LED strips will take you deep into the construction of this super flexible fixture. So, if you want to know the LED strip from its root, this article is for you!

The PCB of the LED strip light gives the fixture a tape or rope-like structure. It is basically the main construction body of the LED strip within which other tiny components reside. These include LED chips, resistors, capacitors, etc. And all these words combined to make the LED strip glow. However, voltage rating is essential to ensure optimal lighting performance.

In this article, I have covered all the basic information about the internal schematic of LED strip lights and their voltage requirements. If you are not familiar with LED strip lights and want to know about them, this guide will be your best option to start with-

Internal Schematic of LED Strip Lights

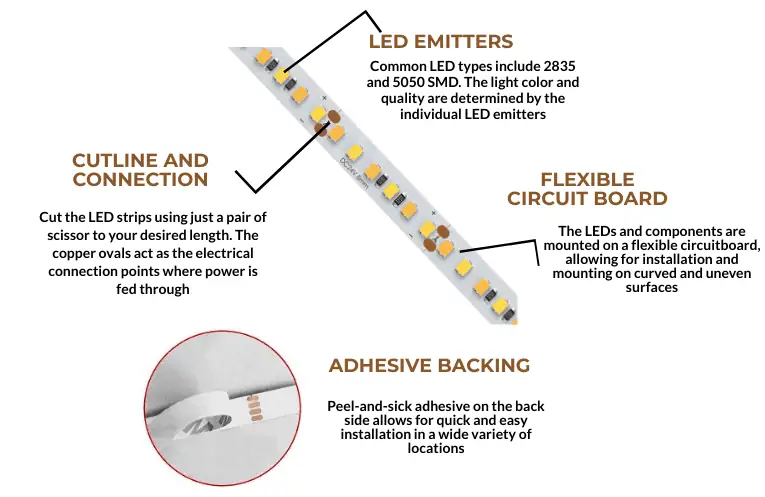

The internal schematic of the super thin and flexible LED strips will amaze you; they are composed of numerous tiny components. The basic internal components of LED strips are as follows-

- LED Bead

An LED bead is the main component of an LED strip that emits light. They are made of semiconductor particles that glow when electricity is passed through them. Numerous tiny LED beads are arranged within the LED strips. These beads can be of different sizes. The lighting output of the LED strip lights depends on the number, size, and shape of these beads. To know more, check this- Numbers and LEDs: What Does 2835, 3528, and 5050 Mean?

- Circuit Board

All the elements of the LED strips are arranged in a printed circuit board, usually termed PCB. These boards are super flexible, allowing you to shape the strip lights as required. The most interesting fact about the PCB is that they have cut markings throughout the body. You can cut it following the marking using a scissor. This helps you to size the strips as per the installation needs. Check Can You Cut LED Strip Lights and How To Connect: Full Guide to learn how to cut LED strips.

- Resistor

The resistor in the LED strip lights controls the current flow within the strips. If the fixtures run through excessive current, they get damaged. Resistors are installed to prevent such a situation. It keeps the voltage and current flow in check, ensuring optimal performance.

- Capacitor

The capacitor is used in LED strips to ensure an even and consistent illumination. It stabilizes the power supply and reduces flickering or other unwanted electrical effects. However, all LED strips don’t come with capacitors. It is usually found in advanced strip lights with ICs; Basic LED strips may also have a capacitor.

- Diodes

It is crucial to maintain a direction of current flow throughout the LED strips. If, by chance, the current flows reversely, it will damage the LED chips. For these reasons, diodes are used to ensure current flows only in one direction. These are semiconductor devices that also have color-controlling ability. For example, in RGBX LED strips, you can control the intensity of each color (red, green, & blue) by adjusting the current passing through each diode. Thus, it allows you to create up to 16 million hues. Check this to learn more: RGB vs. RGBW vs. RGBIC vs. RGBWW vs. RGBCCT LED Strip Lights.

- Copper Traces

The copper traces on the PCB of the LED strips work as an electric conductor. It creates a pathway for the current flowing from the power source to individual LED strips and other components. Thus, it connects LED chips, resistors, diodes, and other circuitry. This ensures even electricity distribution throughout the length of the LED strip.

Basic Fundamentals On Voltage

The voltage of LED strips depends on two factors-

The Voltage of the LEDs, Their Components, And The Power Supply

When determining the voltage of the LED strip lights, you need to consider three factors. These are as follows-

- LED Voltage

The LEDs used in the strip lights have an individual voltage requirement. This voltage is usually termed as ‘Forward Voltage’ or ‘VF.’ It is the minimum voltage that an LED needs to emit light. The requirement of this voltage varies with the type and color of LED. For example, a white LED usually needs around 3 to 3.4 volts. This may vary for other colors of light. The chart below shows you the forward voltage range of LEDs for different colors-

| LED Color | Typical VF Range |

| Red | 1.8 to 2.1 volts |

| Amber | 2 to 2.2 volts |

| Orange | 1.9 to 2.2 volts |

| Yellow | 1.9 to 2.2 volts |

| Green | 2 to 3.1 volts |

| Blue | 3 to 3.7 volts |

| White | 3 to 3.4 volts |

- Components Voltage Compatibility

LED strips are composed of different components. These include- resistors, diodes, and capacitors. Each of these components’ voltage must match the LED’s voltage. If the voltage doesn’t match, it can damage the components or lead to malfunction.

- Power Supply Voltage

The voltage of the power supply is known as the ‘input voltage’ or ‘supply voltage.’ It is the external voltage that is provided to the fixture. As LED strip lights are voltage-sensitive, it is essential to ensure that the voltage of the LEDs and their components matches the voltage of the power source. For example- if you have a 12-volt LED strip, you must use a 12-volt power supply. If you use higher or lower voltage, the LED strip lights will not perform optimally.

Configuration Of The LEDs

The LEDs of an LED strip light can be arranged in two types of configuration- series and parallel. These are discussed below-

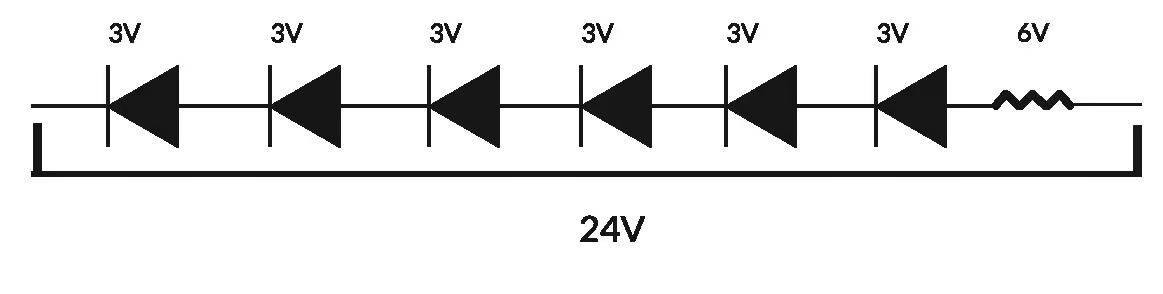

Series Circuit

In a series circuit, the LEDs of the PCB are connected end-to-end. That is, the ending of one LED chip is connected to the starting of the other. As a result, the current flows through each LED in sequence. In a series circuit, an equal amount of current is passed through all the LEDs, and the voltage is added up. For example, if you have n number of LEDs in an LED strip, the total voltage of the strip light will be n times the VF of a single LED.

Pros:

- Efficiently utilize the supply voltage.

- Fewer connections and components are needed

- Easy circuit configuration

Cons:

- One LED failure can disrupt the entire circuit

- Variations in Vf among the LEDs can lead to uneven illumination

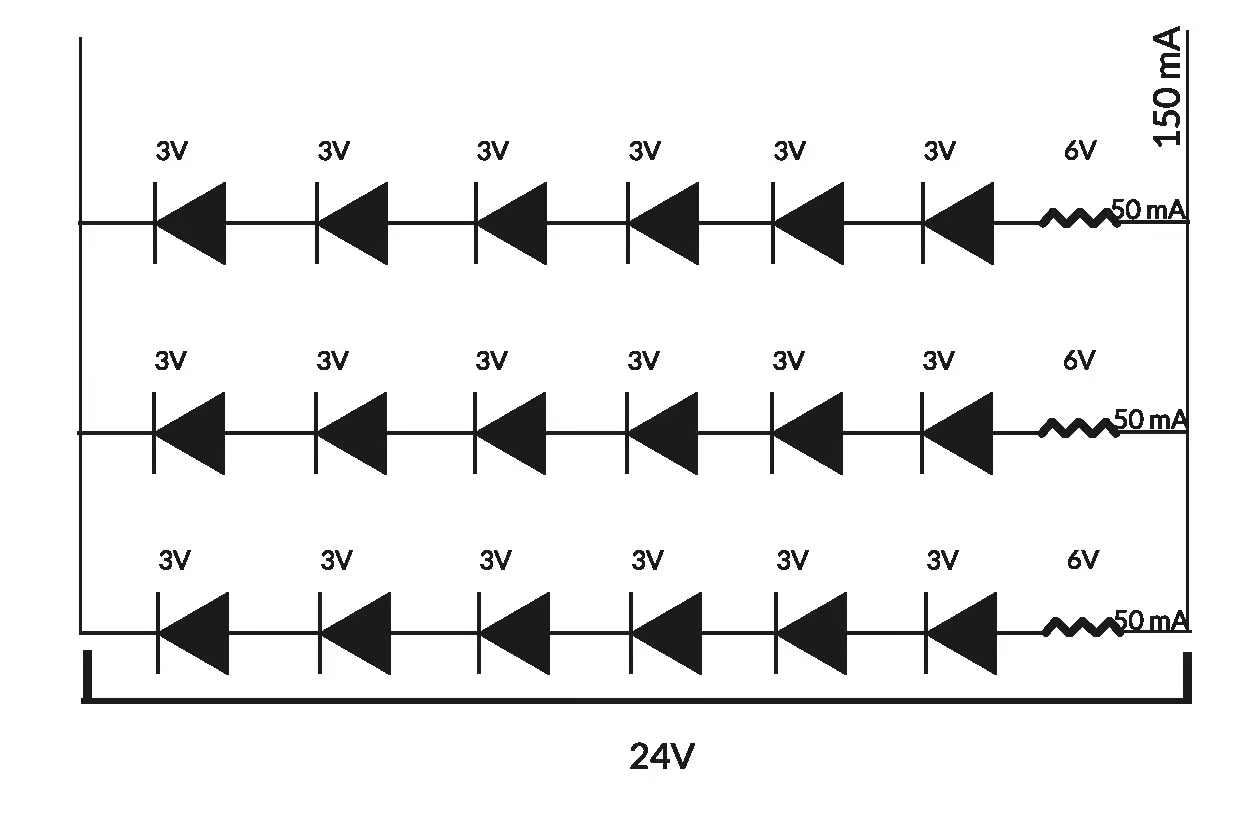

Parallel Circuit

In a parallel circuit, several LEDs are linked side by side, each with a distinct branch. Each of these branches is directly connected to the power source. As a result, the voltage across each component remains constant. However, the current is distributed among the branches.

Pros:

- If one LED fails, others continue to operate

- Each LED can be controlled independently

- Facilities advanced lighting features like color mixing or animation

Cons:

- Complex circuit configuration

- require more wiring

- Uneven power distribution

- The brightness of all LEDs is not the same

Voltage Ratings For LED Strips

Usually, LED strip lights are considered as low voltage light fixtures. But high voltage variants are also available. The voltage ratings of the LED strips are as follows-

Low Voltage LED Strip

Most of the LED strip lights usually come in either 12V or 24V. The first is ideal for interior lighting; you will also find them in automobile lighting- The Complete Guide to 12 Volt LED Lights for RVs. Meanwhile, 24V LED strips are mostly used for outdoor or commercial lighting. In comparing both the strips, a 24V LED strip is more efficient than a 12V one. To know how to choose the voltage rating for LED strips, follow this guideline- How to Choose The Voltage of LED Strip? 12V or 24V? However, low-voltage LED strips of 5V are also available. Most of the USB power LED strip lights usually have a 5V rating. Below, I am adding a quick comparison chart of low-voltage LED strips-

| Low Voltage LED Strip Comparison: 5V vs. 12V vs. 24V | |||

| Total Voltage of LED Strip | Voltage Across Resistor | % Power “Wasted” On Resistors | Application |

| 5V (1 LED Per Group) | 2V | 40% | Portable devicesUSB-powered lighting DIY projects Small accent lighting |

| 12V (3 LEDs Per Group) | 3V | 25% | Automotive lightingRV lightingUnder-cabinet lightingHome decor and accent lighting |

| 24V (6 or 7 LEDs Per Group) | 3V | 12.5% | Commercial and industrial lightingArchitectural lightingLarge-scale installations Outdoor signage and illumination |

High Voltage LED Strips

You don’t need divers or cumbersome transformers for high-voltage LED strips. They can be of different voltage ratings, including- AC110V, 120V, 230V, and 240V. They can be as long as 50 meters with just one plug-in. These make high-voltage LED strip lights suitable for commercial and outdoor lighting.

Application of high-voltage LED strips

- Street Lighting

- Stadium Lighting

- Industrial Facilities

- Outdoor Area Lighting

- High-Bay Lighting

- Large Commercial Spaces

- Cove Lighting

- Stairway Lighting

LED Strip Voltage Drop

The voltage decreases along the length of the LED strip as the current flows within it is known as the voltage drop of the LED strip. Due to voltage drop, the brightness of the LED strip gradually decreases as the length proceeds away from the power source. The factors that affect the voltage drop are as follows-

- The total current of the LED strip

- Length and diameter of the wire

- Length and the thickness of the copper in the PCB

To learn more about LED strip voltage drop, check this- What is LED strip voltage drop?

How To Reduce LED Strip Voltage Drop?

The brightness and the overall lighting output are badly affected due to voltage dropage. Here are the ways following which you can reduce LED strip voltage drop in the following ways-

1. Use High Voltage LED Strips

High-voltage LED strips are less prone to voltage drop. If you are facing voltage drop issues using 12V or 24V LED strips, I suggest you choose high-voltage LED strips. It can be a 48Vdc or 36Vdc LED strip or 110Vac, 120Vac (or higher) that suits your lighting purpose. But whatever you choose, make sure the voltage of the LED strip is compatible with the voltage of the power source.

2. Shorten The LED Strip Length

The voltage drop and the current flow resistance increase with the length increase.

Length ⬆ Voltage ⬆ Voltage Drop ⬇

That is why shortening the length of the LED strip will reduce the voltage drop. To know more about the length of LED strips and their voltage, check this- What Are the Longest LED Strip Lights?

3. Parallel Wiring Multiple Strips

When you connect multiple LED strips to increase the length, it causes a voltage drop. As a result, the brightness of the LED strip starts to dim gradually as the length increases. To avoid such issues, connect parallel wirings from the power source to each newly added LED strip. This will reduce the voltage drop.

4. Use Thicker and Wider PCB

All the components of the LED strip are arranged within its printed circuit board or PCB. It also contains the resistor. As the length increases, the resistance also increases, which causes a voltage drop. But you can reduce the voltage drop by using a thicker and wider PCB.

Do You Have To Supply Exactly The Voltage Specified?

LEDs are voltage-sensitive. That is why it is essential to supply accurate voltage to the LED strip lights for optimal performance. However, there is a tolerance range up to which LEDs can intake voltage. If the supplied voltage exceeds the tolerance level, the fixture will be damaged.

The operating voltage of LEDs is known as forward voltage or VF. For example, if the VF of an LED is 3.2 volts with a tolerance of ±0.1 volts. This indicates that the LED strip light can work properly within the range of 3.1 volts to 3.3 volts. If the supplied voltage exceeds this, it will damage the LED. That is why it is better to supply the voltage exactly as per the specification.

FAQs

The reduction of energy of a supplied voltage as electric current flows through the elements is known as voltage drop. It may be caused by several reasons, including- current load, resistance, increases in the wire length, etc.

LED strips are low-voltage light fixtures that usually come in 12V or 24V. But high-voltage LED strips can also be as high as 240V (AC).

LED strips can be either constant voltage or constant current.

Constant Voltage:

Needs a fixed voltage, usually 12V or 24V.

Easier to install.

Common for home use.

Constant Current:

Operates at a fixed current, like 350mA.

Used in professional settings.

Requires a specialized driver.

Choose based on your project needs.

Low-voltage LED strips of 12V or 24V need a transformer to convert the high voltage of the power supply to a suitable rating. But high-voltage LED strips don’t require any transformer.

No, you can’t run 24V LED strips on 12V. The forward voltage of a 24V requires the exact voltage supply. It won’t operate correctly or may not work at all if less voltage is supplied.

Check the packaging of the LED strip to know its voltage ratings. Inspect the strip body for voltage ratings if you can’t find it in the packaging.

The Bottom Line

The LED strip lights are versatile lighting fixtures suitable for multiple applications. They are available in both high and low voltage. But whatever the voltage you choose, ensure it matches the input voltage. To learn more about LED strip lights, check this article- How Do LED Strip Lights Work?

For premium LED strips, choose our LEDYi LED strips. We have many collection and customization facilities to meet your needs. Besides regular fixtures of 12V and 24V, we also have constant current and high voltage LED strip series. Check them and place your order now!