Have you bought a non-waterproof LED strip and are looking for the best glue to waterproof it? Let me help you pick the right one!

There are four gluing options for waterproof LED strip lights: epoxy resin glue, PU glue, silicone glue, and PVC. Of all these options, silicone glue works the best. It has high thermal conductivity, is resistant to temperature (high and low), doesn’t get yellowish, and is environmentally friendly. However, silicon glue is expensive compared to other glues.

Explore all the available gluing options for LED strip waterproofing in this guide. Besides, I have also added alternative options for making your strip lights water-resistant. So, let’s dive in:

Why Is Glue Used in LED Strips?

Applying glue to LED strips creates a protective coating that makes them waterproof. This prevents dust, dirt, moisture, or water from directly contacting the LEDs. Thus, gluing makes LED strips water-resistant and suitable for outdoor use and applications with high moisture content. Besides waterproofing, glue is used to seal the endings and connections in LED strips.

Different Types Of Glues For Waterproof LED Strip

1. Epoxy Resin Glue

Epoxy resin glue is popular for its affordability. This is mostly used in cheaper LED strips. However, there are some prominent drawbacks to using LED strips with epoxy resin glue. The foremost one is their tendency to turn yellow. Within a few months of use, you will find the fixture getting yellowish. As a result, it doesn’t show the accurate color temperature of the light.

They further have poor heat dispersion properties. That is, this glue heats up easily, directly influencing the LEDs’ lifespan. Besides, epoxy resin glue is highly intolerant to high and low temperatures; its operating temperature ranges between 0-60℃. If the temperature rises below 0℃, they tend to harden and crack.

| Pros | Cons |

| – Low price – lower toxicity – Good maneuverability | – Easily turns yellow – Sensitive to high and low temperature – Overheats quickly |

2. Polyurethane (PU) Glue

Polyurethane, commonly known as PU glue, is a better LED strip glue than epoxy. Though it is expensive, PU glue is highly resistant to yellowing. So, unlike epoxy glue, you won’t face color temperature-changing issues with PU glue. It also has a high thermal conductivity that doesn’t let your LEDs overheat easily, contributing to its lifespan.

Nevertheless, the major drawback of PU glue is that it produces some very toxic low-molecule compounds while solidifying. These are harmful to health and also smell bad. Moreover, PU glue is not resistant to high temperatures. You can’t install an LED strip with PU glue in any location where the temperature is higher than 80 ℃.

| Pros | Cons |

| – High transparency – Resistance to yellowing – Resist low temperature – Better thermal conductivity | – Expensive – Toxic to health – Bad smell – Not resistant to high-temperature |

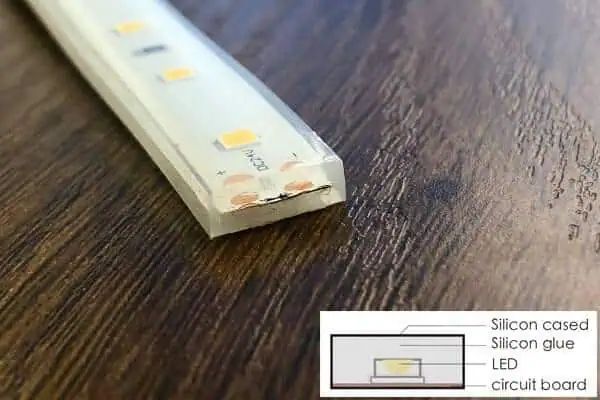

3. Silicone Glue

Silicone glue is used in high-grade and premium-quality LED strips. It offers the benefits of both epoxy resin and PU glue. Silicone glues are highly UV resistant and can face scorching sunlight. You can use LED strips with silicone glue for years without facing any color degradation due to resistance to yellowing.

This makes them suitable for outdoor and commercial spaces like hotels, restaurants, shopping malls, etc. Besides, the anti-corrosive property of silicone glue is also worth mentioning. You can use them on chemical plants, wet seasides, chemical plants, or petrol stations.

Moreover, they have better thermal conductivity that manages heat dispersion effectively. Silicone glue is further resistant to low and high temperatures. LED strips with these glues can operate at temperatures ranging from -40 °- 220°. Therefore, you can use these fixtures on refrigerators or even in saunas. They also don’t produce any toxicity as PU glues and are safe to use.

| Pros | Cons |

| – High heat conductivity – Resist yellowing – UV resistant – Anti-corrosive – Resistant to low and high temperature – Environment-friendly | – Expensive |

4. PVC

PVC, also known as polyvinyl chloride, is a common plastic. It is used as the outer coating of an LED strip for water resistance. However, they don’t provide higher waterproofing of IP65 as silicone glue. PVC is, in fact, cheap and produces toxins like HCl and other chlorinated substances. It’s not very transparent and easily gets yellow. Besides, the thermal conductivity of PVC is also low. However, being the cheap variant, it is widely used in high-voltage LED strips.

| Pros | Cons |

| – Cheap | – Not highly water-resistant – Not environment-friendly – Poor heat conductivity |

Epoxy Resin Glue Vs PU Glue Vs Silicone Glue Vs PVC – Which Is Best For Waterproofing LED Strip?

| Criteria | Epoxy Resin Glue | PU Glue | Silicone Glue | PVC |

| Cost | Low | High | Highest | Cheapest |

| Temperature resistance | 0-60℃ | -40-80℃ | -40-220℃ | Up to 65°C |

| Heat conductivity | Low | High | High | Low |

| Yellowing | Yes (within six months) | No | No | Yes |

| Toxicity | Low | High, bad smell | No | High |

| Light transmission rate | 92% | 95% | 96% |

Comparing all the features and resistance levels, it’s quite clear that silicone is the best glue for waterproof LED strips. It is tolerant to high and low temperatures, has high heat conductivity, and doesn’t get yellow. Above all, it is environmentally friendly and emits more light.

When You Need a Waterproof LED Strip? – Application

The waterproof LED strip is used for outdoor lighting and places with high moisture content where the fixtures come into close water contact. For example, installing fixtures in kitchens, bathrooms, gardens, roofs, outdoor patios, etc., requires waterproofing.

However, the intensity of waterproofing differs for different applications. For instance, the LED strip you use for swimming pool lighting needs more waterproofing than your kitchen area’s fixture.

DIY: How To Waterproof LED Strip Lights Using Glue? – Stepwise Process

If you have bought a non-waterproof LED strip, you can easily make it waterproof using glue. Here is how to do this:

Step 1: Collect Material Needed For Waterproofing

First, collect the following materials and move to the next step for waterproofing:

- LED strip lights (non-waterproof)

- Clear silicone glue or waterproof adhesive (e.g., epoxy)

- Plastic or rubber gloves

- Scissors

- Rubbing alcohol or a clean cloth

- Masking tape (optional for clean edges)

Step 2: Prepare The LED Strip For Gluing

Take the LED strip and cut it to your required size. Make sure you follow only the cut marks. After that, clean the LED strip with a soft cloth or rubbing alcohol to remove dirt, dust, or oil on the PCB. This will ensure the glue sticks thoroughly throughout the LED strip.

Step 3: Apply Glue

Now, place the LED strip on a clean surface and apply the glue from top to bottom and on the edges. Use a small brush or the tip of your fingers (wearing gloves) to spread the glue evenly. For a finished look, use masking tapes on the ends of the LED strips before gluing. So, as you remove the tape after gluing it, it will create neat ends.

However, don’t apply the glue on the back of the LED strip as it contains the adhesive for installation. Let the glue dry completely. Once it is dry, you can double-coat it to ensure complete waterproofing. But don’t overdo it; this will mess up the outer surface, which can affect the final light output.

Step 4: Secure & Power The LED Strip

Apply end caps to lock up the edges. If you are connecting multiple LED strips, secure the connections, too. Use waterproof connectors for this process and properly seal them up. Once the LED strip is completely sealed, connect it to the power supply to test if it glows. The light will surely glow if you maintain the correct polarity and all the connections are done appropriately.

Step 5: Test the Waterproofing Of The LED Strip

Now, sprinkle water on the LED strip and look for any failures. But before that, you must visually inspect if any space lacks gluing; otherwise, it can be risky. For more assurance, you can connect the LED strip to a multimeter and sprinkle water on it to observe any changes in performance. If everything is working well, you have just turned your regular LED strip into a waterproof one using glue!

However, for more accurate waterproofing testing, you can follow the standard test methods as followed in IP tests. Two digits indicate the IP rating—the first one defines the protection against solids, and the latter one is against liquids. As we are testing for waterproofing, you must follow the test method for liquid ingress (2nd digit).

| Waterproofing Test (Determining IP Ratings) | ||

| IP Rating (For 2nd Digit) | Protection Against | Test duration: 10 minutes Withstand Water: 1 mm (0.039 in) rainfall per minute |

| IPX1 | Dripping water | Test duration: 10 minutes Withstand Water: 1 mm (0.039 in) rainfall per minute |

| IPX2 | Dripping water when tilted at 15° | Test duration: 10 minutes ( 2.5 min in each direction)Withstand water: 3 mm (0.12 in) rainfall per minute |

| IPX3 | Water spray | – For Spray Nozzle Test duration: 1 min/sq.m for at least 5 min Water volume: 10 liter/min Pressure: 50 -150 kPa – For Oscillating Tube Test duration: 10 min Water volume: 0.07 liter/min |

| IPX4 | Water splash | – For Spray Nozzle without shield Test duration: 1 min/sq.m for at least 5 min – For Oscillating Tube Test duration: 10 min |

| IPX5 | Water jets | Test duration: 1 min/sq.m for at least 3 minutes. Water volume: 12.5 liters/min Pressure: 30 kPa at a distance of 3 meters |

| IPX6 | Powerful water jets | Test duration:1 min/sq.m for at least 3 minutes Water volume: 100 liters/min Pressure: 100 kPa at a distance of 3 meters |

| IPX6K | Powerful water jet with high-pressure | Test duration: 3 minutes (minimum) Water volume: 75 liter/min Pressure: 1,000 kPa at a distance of 3 meters |

| IPX7 | Immersion up to 1m | Test duration: 30 min. The enclosure is tested with the lowest point 1,000 mm (39 in) below the water’s surface or the highest point 150 mm (5.9 in) below the surface, whichever is more profound. |

| IPX8 | Immersion on 1m or more | Test duration: Manufacturer-specified depth, typically up to 3 meters |

For more details, go through this article- IP Rating: The Definitive Guide.

Other Alternatives Of Gluing To Make LED Strips Waterproof

a. Use Pre-waterproof LED Strip

If you don’t want to take the hassle of gluing your LED strips, the best alternative is to purchase pre-waterproof strips. These fixtures are available in different IP ratings to provide suitable and reliable water protection. For instance, you can use IP68-rated LED strips for submerged lighting installations. However, these strips are more expensive than the non-waterproof ones, but surely, these offer accurate waterproofing. You will also get waterproof test reports from the manufacturer for reliability. To learn more, read this- A Guide to Waterproof LED Strip Lights.

b. Heat Shrink Tube

Heat shrink tubes are thermoplastic tubes that shrink as they come in contact with heat. These tubes are thin and flexible and work excellently for waterproofing LED strips. You can use them directly on the non-waterproof LED strip or use them after gluing for extra protection.

You only need to insert the LED strip inside the heat shrink tube and blow it with a heat gun. The hot air from the dryer shrinks the tube and completely seals the LED strips. However, you must use waterproof end caps on both sides of the LED strip for complete sealing.

c. Silicone Sleeve

Silicone sleeves are tubes made of flexible and transparent silicone. They protect the LED strip from moisture, dust, and water, making them dust and waterproof. You can bend these sleeves and shape them as you need. They are excellent for kitchen, under-cabinet, and bathroom lighting.

However, compared to heat shrink tubes, they are thicker but have the same level of water resistance. Using these silicone sleeves is also super easy. Just insert the LED strip in it and close the ends with silicone caps.

Silicone sleeves are available in different shapes and profiles- round shape (tube), flat shape, U-shape, V-shape(for corner), D-shape (half-round), and other customized shapes. Therefore, you can use them in a versatile way. I’m pointing out two examples of the versatile ways you can use these silicone sleeves for waterproofing your LED strips:

– Silicone Sleeve+Silicone Glue Coating

The U-shaped silicone sleeves have a one-side opening. You need to place the LED strip inside the sleeve so that the U-shape remains at the back of the LED strip and the LEDs face the open side. Now, seal the opening with silicone glue. This way, the entire LED strip is waterproofed. However, such a method is not suggested for direct submerged applications.

– Silicone Sleeve+Silicone Glue Injection

This method is ideal if you want to install the LED strips underwater. Here, you need a hollow, enclosed silicon sleeve. Then, insert the LED strip and inject silicone glue into it. This creates a robust sealing that is ideal for immersing the fixture underwater. This waterproofing method can light up swimming pools and fountain lighting.

d. Waterproof LED Channels or Housings

Waterproof LED channels, or housing, are aluminum channels with see-through covers. These act as an outer cover of the LED strips, protecting them from the outer environment. The cover of the channel is made of polycarbonate or acrylic. These can be clear or frosted.

Besides, a wide range of shapes and colors are available. Our LEDYi aluminum profiles are available in white, black, and silver with a length of 0.5-3M. Our Waterproof Aluminum profiles have an ingress progress of IP65 and are available in various wattages.

Tips For Using Waterproof LED Strip Light

Choose the Right IP Rating

You must consider the application to track the suitable IP rating for your LED strip. For example, when using an LED strip in the bathroom, you will need an IPX7 in the shower area. However, the fixtures installed around the bathroom shower area will work well with an IPX4 rating. Again, if you want to mount the LED strips inside the swimming pool, you will need an IPX8-rated LED strip. Therefore, select the IP rating considering the water contact level.

Seal The LED Strip After Cutting

If you cut a waterproof LED strip, it no longer remains water-resistant. The silicon or PU glue over the LED strip gets removed at the cutting points, allowing water to get into the edges of the strip easily. Therefore, when you cut a waterproof LED strip, use silicone glue on the endings, connecting, or cutting points. Use heat sink tubes to seal the LED strips completely for more assurance.

Consider Temperature To Pick The Right Glue For Waterproofing

Temperature is a crucial factor to consider when choosing waterproof LED strips. The types of glues used for waterproofing have variations in temperature resistance. For instance, epoxy resin glue and PVC are not suggested for LED strips used in high temperatures.

However, if you ask for the best temperature-resistant glue, the one with silicon will undoubtedly win the match. That is why reputed LED strip manufacturers use either PU or silicone for waterproofing. You can use them in freezing cold weather or in extreme hot applications. For instance, our LEDYi sauna LED strips use a food-grade silicone extrusion process that offers an IP65 rating. It can tolerate -25°C ≤ Ta ≤100°C.

FAQs

Yes, you can use hot glue on LED lights to waterproof them. However, it’s not a highly recommended option as LEDs are heat-sensitive. Applying hot glue can lower the lifespan or permanently destroy the LED strip.

No, not all LED strips are waterproof. The waterproofing of the LED strip depends on its IP rating. However, you must know that waterproofing and water resistance are not the same thing. IP66, IP67, and IP68 are waterproof; they are completely sealed. Meanwhile, IP65 or lower is considered water-resistant. Nevertheless, a lower rating means less resistance to water.

No, super glue is not recommended for waterproofing LED strips. Firstly, it emits heat, which can damage them. Secondly, it is not flexible; applying it to LED strips will make them rigid and can easily break. Above all, it is a bonding material and doesn’t have robust waterproofing properties.

If your LED strip adhesive backing has lost its stickiness, you can easily replace it with a new one. All you need to do is buy a 3M double-sided adhesive and paste one side to the LED strip, and it’s done. While installing, simply tape off the other side and stick it on the surface.

Check the IP rating to determine if your LED strip is waterproof. However, you can physically inspect the fixture. It is water resistant if it has a silicon, PU, epoxy resin, or PVC coating. If you find bare LEDs on the strip, it is not waterproof.

Conclusion

After all these discussions, if you ask me about the best glue for waterproof LED strips, I will generally suggest silicon glue. However, considering the application is essential as silicon glue is highly expensive. If you need glue for some DIY fun project, investing in this glue may be a waste of money. In this case, you can choose cheaper alternatives like- epoxy resin glue or PVC. However, if you want a durable and better solution, choose either PU or silicon. Not to mention, PU glue is toxic but cheaper than silicon.

Nevertheless, pre-waterproof LED strip lights are your ultimate solution to avoid these gluing hassles. Share your water-resistant requirements with us, and we will provide you with the ideal IP-rated LED strip. We further provide customized solutions to meet your specific needs. So, why wait anymore? Place your order now on LEDYi!