LED lighting is widely used because of its effectiveness, durability, and long lifespan. One of the trickiest things about utilizing LEDs is controlling their brightness. Here, PWM dimming is relevant. control of LEDs PWM dimming is a method for regulating LED brightness by altering the pulse width of the electrical current. PWM dimming is becoming more and more well-liked as a practical and effective method of controlling LED lights.

What is PWM dimming?

PWM’s ability to control a variety of devices in each field of electronics is largely responsible for its widespread use in the modern electronics industry. PWM signals are used to dim LEDs, control motors, and run an assortment of different electrical equipment. Hence, what is the functionality of the PWM methodology?

PWM is a method for reducing the average deliverable power of an electrical signal. In addition, the procedure is completed by successfully separating the signal into its constituent parts. In terms of functionality, the switch between the load and the source may be swiftly turned on and off to regulate the average current and voltage supplied to the load.

By varying the amount of time the signal is high (ON) or low (OFF), PWM allows for a wide range of brightness (OFF). In contrast to analog dimming, which dims LEDs by altering output power, the PWM signal may either be ON or OFF at any one time, meaning that the LEDs will either get the full voltage or no electricity (i.e., providing 10V instead of 12V to alter brightness).

What is Constant Current Reduction (CCR)?

The continuous current reduction technique provides a steady current flow to the LED (CCR). In contrast to the PWM method, in which the LED state fluctuates between on and off, the LED is constantly on. Yet, you may control the LED’s brightness by adjusting or changing the current levels using CCR.

Advantages of the CCR Dimming Method:

- Ideal for remote applications that require long wire lengths and stringent EMI specifications.

- CCR drivers have higher output voltage restrictions (60 V) than PWM drivers (24.8 V). These specifications apply to Class 2 drivers that are UL-certified for use in both moist and dry environments.

Disadvantages of the CCR Dimming Method:

- LEDs’ inconsistent light generation at very low currents renders the CCR method inappropriate for applications requiring dimming below 10% of maximum brightness. In conclusion, the LED performance produced by this method at these present levels is subpar.

- Low driving current leads to an inconsistent hue.

PWM as A Dimming Signal

Let’s expand on our current understanding of pulse width modulation. Now, the PWM must be recognized as a signal.

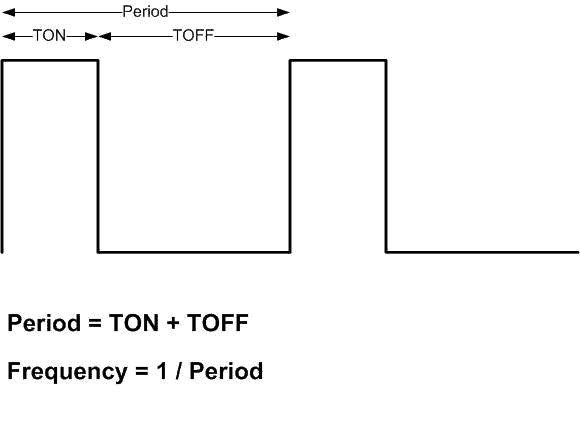

Pulse width modulation signals consist of sequences of square-wave-shaped pulses (PWM). There are peaks and valleys in the waveform of every signal. The on-time is when the signal strength is high, whereas the off-time is when the signal strength is low.

Duty Cycle

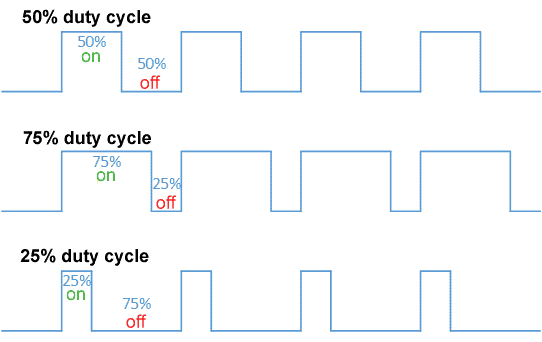

The duty cycle is when the signal can remain high in the dimming concept. Hence, the signal has a 100% duty cycle if it is always on. The PWM signal’s on-time can be adjusted. When the PWM duty cycle is set to 50%, the signal runs 50% of the time on and 50% off.

Frequency

The pulse width modulation (PWM) signal frequency is another essential component. The PWM frequency determines how quickly a period—the amount of time it takes for the signal to turn on and off—is completed by the PWM signal.

PWM as LED Driver Output

When the PWM signal is converted to a DC voltage and used as an LED driver output, pulse width modulation occurs. The PWM output circuit cuts the DC LED currents between the on and off states at a high frequency. Hence, the flicker that causes a shift in the LED light output is invisible to the human eye.

People frequently confuse a few things regarding the distinctions between PWM output and dimming signal. So let’s take note of a few things.

The mechanism produces a PWM signal as a digital signal, which makes it consistent on the dimmable cable. In contrast, the driver determines the output current by detecting the PWM duty cycle.

PWM Dimming Drivers in the Market

PWM dimming drivers are becoming increasingly crucial for LED lighting. Nonetheless, it is necessary to know that PWM dimming drivers might be realized in two different ways, and let’s find out what they are.

Fake PWM Dimming

The purpose of the fake dimming method is to convert PWM inputs into an analog control signal. A resistor-capacitor (RC) filter resides within the driver.

The RC filter converts the PWM signal to a proportional DC voltage based on the duty cycle. Fake PWM dimming has the advantage of being noiseless, and there is no noise at the output because the LED current is continuous.

Nevertheless, this method is problematic since the precision is poor if the PWM’s peak value is below 10V. Moreover, the resistor-capacitor (RC) value limits the frequency of the PWM signal.

Real PWM Dimming

In real PWM dimming, LED currents switch on and off at the frequency and duty cycle specified. The presence of the MCU or microcontroller in the driver enables the PWM signal to detect peak voltages. Real PWM dimming supports a broader spectrum of PWM frequencies.

A fundamental feature of PWM dimming is its ability to maintain the white point of the LED output. In addition, an elevated reference voltage level exceeding offset errors is permitted.

The driver development software requires users to pick PWM dimming mode.

Altering the Duty Cycle (brightness) With PWM

While the supply is switched ON and OFF so rapidly utilizing pulse width modulation output, the LEDs do not flicker. Duty Cycle is the term used to describe the measurement of PWM brightness.

The duty cycle is the proportion of the circuit’s runtime that it is ON. The duty cycle is expressed as a percentage, with 100 percent representing the brightest feasible condition (fully ON) and lower percentages resulting in poor LED light output.

The PWM signal has a 50% duty cycle if it is on 50% of the time and off 50% of the time. The signal appears as a square wave, and the brightness of the lights should be about average. When the percentage is greater than 50%, the signal spends more time in the ON state than in the OFF state, and vice versa when the duty cycle is less than 50%.

Pulse Width Modulation (PWM) vs. Analog Dimming of LEDs

With the exponential growth of LED lighting on the market, there has been a natural rise in demand for highly efficient and precisely regulated LED drivers. To preserve the energy-efficient strategy and end-use flexibility of LED design, “smart” street lights, flashlights, and digital signs, among other uses, require precisely controlled currents and, in many cases, dimming functionality.

PWM Dimming

With pulse width modulation (PWM) dimming, the LED current is momentarily on and off. To prevent a flickering effect, the on/off frequency must be quicker than what the human eye can perceive (usually over 100Hz). PWM dimming can be implemented via a variety of methods:

- Using a PWM signal to change voltage directly.

- By way of an open collector transistor

- By a microcontroller.

The average current of an LED is equal to the sum of its total nominal current and its dimming duty cycle. The designer must also take into account the delays in converter output shutdown and startup, which impose limitations on the PWM dimming frequency and duty cycle range.

Analog Dimming

Adjusting the LED current level is referred to as analog dimming. Using an external DC control voltage or resistive dimming can accomplish this. Despite the fact that analog dimming now allows for level adjustment, the color temperature can shift. Analog dimming is not recommended for applications where the hue of the LED is essential.

Let’s take a look at the primary differences between PWM & analog dimming

| PWM Dimming | Analog Dimming |

| Brightness is adjusted by modulating the peak current in the driver | Brightness adjusted by changing the DC going to the LED |

| No Color Shift | Possible Color Shift as LED current changes |

| Possible current inrush problems | No inrush current to device |

| Frequency limitations & possible frequency concerns | No frequency concerns |

| Very linear change in brightness | Brightness linearity not as good |

| Lower Optical to electrical efficiency | Higher optical to electrical efficiency(>lumens per watt consumed) |

Hardware Considerations For PWM

PWM dimming requires certain considerations when developing the system (or PC board).

A driver is typically necessary with backlight-type LEDs due to the current level. A digital output, like one from a microcontroller, cannot be used to drive it directly.

A straightforward logic level FET (Field-Effect Transistor) type transistor is typically utilized as a driver in various applications. A resistor on the gate must be used to switch the FET to control the gate current, and a resistor is necessary if the current restriction is desired. Make sure you look up the proper backlight driving voltages and currents on the LCD datasheet.

A switching-type LED driver may drive the LED backlight at higher currents and more efficiently. These drivers are more complicated, and a specialist IC often handles the switching function. The PWM input on several ICs is designed expressly for dimming applications.

If a microcontroller is being used, care should be taken to connect to an output pin that supports PWM (timer/counter) output if PWM is used as a hardware function.

PWM – Firmware/Software Considerations

PWM dimming demands particular system design considerations (or PC board).

Because to the high current, backlight-type LEDs typically require a driver. Digital outputs, such as those from microcontrollers, cannot be utilized to directly drive it.

Typically, a simple logic level FET (Field-Effect Transistor) type transistor is used as a driver in a variety of applications. Switching the FET to regulate the gate current requires a resistor on the gate, and a resistor is required if current limiting is desired. Check the LCD datasheet for the correct backlight driving voltages and currents.

A switching-type LED driver may drive the LED backlight more effectively and at greater currents. These drivers are more complex, and the switching function is frequently handled by a specialized IC. Several ICs’ PWM inputs are developed specifically for dimming applications.

If PWM is utilized as a hardware function, attention should be made to connect to an output pin that supports PWM (timer/counter) output on a microcontroller.

PWM Functionality And Applications

When the on and off periods of the switch are shifted relative to one another, the amount of electricity delivered to the load rises. As expected, this type of control offers many advantages.

PWM paired with maximum power point tracking, or MPPT, is one of the primary ways for reducing solar panel output to make it easier for a battery to use it.

PWM, on the other hand, is ideal for powering inertial equipment, such as motors, because this unique switching has less of an effect on them. Due to the linear link between LEDs’ functioning and input voltage, this also applies to LEDs.

In addition, the PWM switching frequency must have no effect on the load, and the resulting waveform must be smooth enough for the load to recognize.

Depending on the device and its function, the switching frequency of the power supply will typically vary significantly. Electric ranges, computer power supplies, and audio amplifiers all require switching speeds in the tens or hundreds of kilohertz range.

Another key advantage of adopting PWM is the incredibly low power loss in switching devices. When a switch is turned off, no current flows through it. In addition, when a switch is on and sending electricity to its load, there is a negligible voltage drop across it.

Related Articles

Everything You Need to Know About DMX512 Control

Everything you need to know About Triac Dimming for LEDs

How To Choose the Right LED Power Supply

DMX vs. DALI Lighting Control: Which One to Choose?

The Ultimate Guide To 0-10V Dimming

FAQs

Yes, PWM dimming is compatible with all LEDs. The LED driver circuitry modifies the PWM signal’s pulse width to regulate the current provided to the LED, allowing for fine control of the LED’s brightness level. Nevertheless, while choosing an LED driver PWM dimming solution, it is critical to consider the electrical specifications of the LED as well as the power supply requirements to guarantee maximum performance and safe operation.

The visual representation of the pulse-width modulation (PWM) signal used to dim LED lights is referred to as a PWM dimming display. The PWM signal is a square wave signal that alternates between high and low voltage levels. The LED’s brightness is determined by the duration of the high voltage level (the pulse width). Typically, the PWM dimming display presents a graph of the PWM signal, with the x-axis indicating time and the y-axis representing voltage levels. Users may utilize the display to see the PWM signal and change the duty cycle to get the desired brightness level.

LEDs use PWM dimming to manage their brightness levels and save energy. LEDs emit light when a current runs through a semiconductor, as opposed to incandescent bulbs, which generate light when heated by an electrical current. This indicates that the brightness of an LED is proportional to the amount of electrical current sent through it.

By altering the pulse width of the PWM signal, the LED driver may vary the current delivered to the LED. The LED driver limits the amount of electrical current delivered to the LED by decreasing the pulse width, resulting in a reduced brightness level. This saves energy and extends the life of the LED.

Moreover, as compared to analog dimming, PWM dimming allows more exact control over the brightness of LEDs. Analog dimming works by lowering the voltage applied to the LED, which can cause flickering and uneven dimming. PWM dimming, on the other hand, gives a more constant and smoother dimming experience.

Overall, PWM dimming is an important technique for adjusting LED brightness and boosting energy economy.

To dim an LED with PWM, you’ll need a PWM-capable LED driver and a controller that can output a PWM signal. The following are the steps for dimming an LED with PWM:

1. Choose an LED driver that supports PWM dimming: Ensure that the LED driver you select supports PWM dimming and is compatible with the LED that you intend to use.

2. Choose a PWM controller: Pick a PWM controller capable of generating a PWM signal compatible with the LED driver you’ve chosen.

Attach the LED driver and the PWM controller as follows: Connect the PWM controller’s output to the dimming input of the LED driver. Always adhere to the wiring schematic given by the LED driver manufacturer.

4. Determine the duty cycle: The duty cycle is the proportion of time that the PWM signal is “on.” The brightness of the LED is determined by the duty cycle. A greater duty cycle produces a brighter LED, whereas a lower duty cycle produces a dimmer LED. Using the PWM controller, set the duty cycle to the desired brightness level.

5. Test and adjust: To get the required brightness level, test the LED and adjust the duty cycle as needed.

Dimming an LED with PWM entails selecting a compatible LED driver and PWM controller, appropriately connecting them, changing the duty cycle, then testing and modifying until the desired brightness level is obtained.

When utilized with LED lights, PWM dimmers can minimize power usage. PWM dimming controls the amount of electrical current sent to the LED, which directly changes its brightness level. The PWM dimmer minimizes the power consumption of the LED by lowering the current delivered to it.

PWM dimming in LED Televisions is a technique for adjusting screen brightness by quickly turning the backlight on and off. It saves energy and improves contrast ratios, but it can also produce flickering and motion blur. To address these concerns, some LED Televisions employ a high-frequency PWM dimming approach.

That is determined by the application. A higher PWM frequency is beneficial for dimming LEDs since it results in less perceptible flicker and smoother dimming performance. A lower PWM frequency, on the other hand, may be beneficial for motor control applications since it minimizes the amount of electrical noise created by the motor.

PWM does not shorten the life of LEDs. PWM dimming, in reality, can assist increase LED life by lowering the amount of electrical current provided to the LED, which can prevent heat accumulation and lengthen the LED’s lifespan.

No, not all LED lights are dimmable. Dimmable LED lights are electrically specified to be utilized with dimming controllers. It is critical to examine the LED light’s box or specs to see if it is dimmable.

It is determined by the LED light. Dimming certain LED lights requires the installation of a suitable dimming control or the replacement of the LED driver with a dimmable LED driver. Nevertheless, not all LED lights can be dimmed, thus it is critical to review the characteristics of the LED light before attempting to dim it.

The best dimmer for LED lights is determined on the kind of LED and LED driver utilized. It is critical to choose a dimmer that is built expressly for use with LED lighting and is compliant with the electrical standards of the LED and LED driver. Certain LED lights require specific types of dimmers, such as trailing-edge dimmers or leading-edge dimmers, therefore before picking a dimmer, verify the package or specs of the LED light.

No, PWM does not alter the voltage provided to the controlled device. It modulates the signal’s duty cycle, which alters the length of time the signal is in the “on” state while keeping the voltage constant.

LEDs may be dimmed using voltage. One way of dimming LEDs is analog dimming, which involves lowering the voltage provided to the LED. PWM dimming, on the other hand, is a more prevalent way of dimming LEDs since it allows smoother and more exact dimming control.

PWM LED dimming is a technique for adjusting the brightness of LED lights by rapidly switching on and off the electricity to the LED. Modulating the pulse width of the electrical current that supplies the LED produces a flicker that is too quick for the human eye to perceive. PWM LED dimming saves energy and provides smoother, more precise dimming control than analog dimming.

No, not all PWM fans operate at 12V. PWM fans come in a variety of voltage levels, including 5V, 12V, and 24V. To verify compatibility with the item being cooled, check the voltage rating of the PWM fan.

Yeah, voltage is important in PWM. The PWM signal voltage must be compatible with the device being controlled. For example, if the device requires a 5V PWM signal, utilizing a 12V PWM signal may cause it to malfunction. To verify compatibility, check the specifications of the item being controlled and the PWM controller.

PWM may be utilized in both alternating current and direct current applications. The PWM signal, on the other hand, must be adjusted to the individual sort of application. The PWM signal must be transformed to an AC waveform using an inverter or equivalent equipment for use in AC applications. The PWM signal can be utilized directly to control the device being powered in DC applications.

No, using a 24V driver for a 12V LED is not advised. To guarantee safe and optimal operation, the voltage supplied to the LED must match the voltage rating of the LED. Utilizing a higher voltage driver might harm the LED and shorten its life. It is critical to choose a driver that matches the voltage needs of the LED.

It is not advised to use a 24V driver with 12V LED lights. When using a higher voltage driver, the LED lights may overheat and fail prematurely. It is critical to choose a driver that is compatible with the voltage needs of the LED lights being utilized.

The ideal PWM frequency for LED dimming is generally considered to be above 100 Hz to avoid visible flicker, and typically around 500 Hz to 1 kHz to avoid audible noise.

To minimize flicker when using PWM dimming, you can use a higher PWM frequency, increase the duty cycle, and use a larger value capacitor in the LED driver circuit. Additionally, you can also use a more advanced dimming technique such as analog dimming or hybrid dimming.

The main advantages of using PWM dimming over other dimming methods are that it is a simple and cost-effective solution, provides a high level of precision, and does not generate much heat. Additionally, PWM dimming is compatible with a wide range of LED drivers and can be easily controlled with a microcontroller or other digital circuitry.

Summary

PWM dimming is a simple and inexpensive method of adjusting the brightness of LED lights. PWM dimming has various advantages over analog dimming, including higher energy economy, more precise control, and longer lifespan. It does, however, present several issues, such as possible EMI and the need for high-frequency switching circuits. However, PWM dimming is an important technique for regulating LED lights, and its future seems promising.

LEDYi manufactures high-quality LED strips and LED neon flex. All of our products go through high-tech laboratories to ensure the utmost quality. Besides, we offer customizable options on our LED strips and neon flex. So, for premium LED strip and LED neon flex, contact LEDYi ASAP!