What is led strip light?

The flexible LED strip light is made of FPC as the assembled circuit board, and the high-brightness LED is used as the light source. The thickness of the LED strip light is only the thickness of a coin, and it does not occupy space. The flexible LED strip light can be cut, and it can also be extended without affecting the light. Because the FPC material is soft, the LED strip light can be bent, folded, rolled, moved, and stretched freely in three-dimensional space without breaking. It is suitable for irregular places and small spaces. Because it can be bent and rolled arbitrarily, it is ideal for various patterns in advertisements and other decorations.

LED strips are widely used in a wide variety of applications. We often need to cut the led strip according to our requirements when we use led strips. But some new beginners do not know how to cut, connect and light LED strips. This article is here to help these people to solve the problem.

The article is mainly divided into 2 parts:

Part 1: Cut, connect and power LED strips by soldering

Part 2: Cut, connect and power LED strips by solder-free connects

Where can I cut led strip?

Before cutting the LED strip, make sure that the LED strip you have purchased can be cut. Otherwise, cutting the LED strip may render it unusable. Also, always remember to disconnect the power supply; it is very dangerous to cut a LED strip that is directly connected to the power supply.

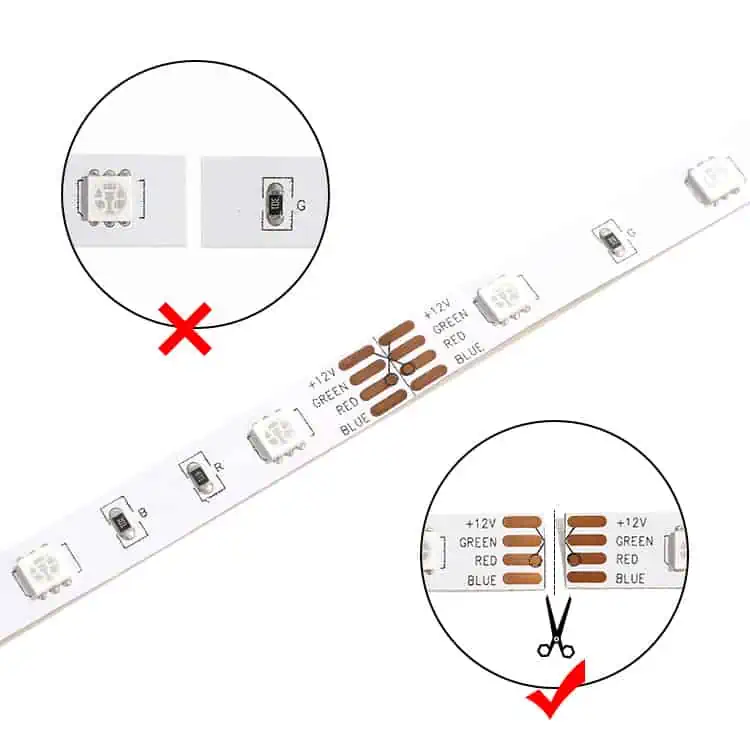

Normally, the led strip is generally divided into 5V, 12V, 24V according to the voltage.

5V is one led per cut

12V is three led per cut

24V is six or seven led per cut

And the led strip will have a black line and a scissors mark at the cut position.

It is very important to cut only on the given cut position when cutting LED strip light. Cutting through or before the cut position will result in no electrical conductivity to the following section.

Part 1: Cut, connect and power LED strips by soldering

1.1 Cut, connect and power IP20 none waterproof SMD LED strip by soldering

Step 1: Measure the length

Step 2: Find the cut position on the led strip

Step 3: Cut the led strip light

Step 4: Soldering cable to led strip light by electric iron

Step 5: Attached the heat shrink tube to protect the soldering point

Step 6: Soldering two-piece led strip together by electric iron

Step 7: Light up the led strip to test

1.2 Cut, connect and power IP20 none waterproof COB LED strip by soldering

Step 1: Measure the length

Step 2: Find the cut position on the COB led strip

Step 3: Cut the COB led strip Light

Step 4: Soldering cable to COB led strip light by electric iron

Step 5: Attached the heat shrink tube to protect the soldering point

Step 6: Soldering two-piece COB led strip together by electric iron

Step 7: Light up the led strip to test

1.3 Cut, connect and power IP52 silicone coating SMD LED strip by soldering

Step 1: Measure the length

Step 2: Find the cut position on the led strip

Step 3: Cut the led strip light

Step 4: Remove silicone from the led strip pad

Step 5: Soldering cable to led strip light by electric iron

Step 6: Fill silicone on the led strip pad

Step 7: Attached the heat shrink tube to protect the soldering point

Step 8: Soldering two-piece led strip together by electric iron

Step 9: Light up the led strip to test

1.4 Cut, connect and power IP65 silicone tube SMD LED strip by soldering

Step 1: Measure the length

Step 2: Find the cut position on the led strip

Step 3: Cut the led strip light

Step 4: Remove 3M tape adhesive

Step 5: Fill silicone in led strip and endcap

Step 6: Put led strip into silicone endcap

Step 7: Clean silicone from led strip

Step 8: Cut off some silicone tube from the strip pad

Step 9: Soldering cable to led strip light by electric iron

Step 10: Fill silicone in led strip and endcap

Step 11: Light up the led strip to test

1.5 Cut, connect and power IP65H heat shrink tube SMD LED strip by soldering

Step 1: Measure the length

Step 2: Find the cut position on the led strip

Step 3: Cut the led strip light

Step 4: Cut off the heat shrink tube from led strip pad

Step 5: Soldering cable to led strip light by electric iron

Step 6: Attached the heat shrink tube to protect the soldering point

Step 7: Soldering two-piece led strip together by electric iron

Step 8: Attached the heat shrink tube to protect the soldering point

Step 9: Light up the led strip to test

1.6 Cut, connect and power IP67 silicone tube & silicone filling SMD LED strip by soldering

Step 1: Measure the length

Step 2: Find the cut position on the led strip

Step 3: Cut the led strip light

Step 4: Remove 3M tape adhesive

Step 5: Fill silicone in led strip and endcap

Step 6: Put led strip into silicone endcap

Step 7: Clean silicone from led strip

Step 8: Cut off some silicone from the strip pad

Step 9: Soldering cable to led strip light by electric iron

Step 10: Fill silicone in led strip and endcap

Step 11: Light up the led strip to test

Part 2: Cut, connect and power LED strips by solder-free connector

2.1 Cut, connect and power IP20 none waterproof COB LED strips by solder-free connector

Step 1: Measure the length

Step 2: Find the cut position on the cob led strip

Step 3: Cut the led strip light

Step 4: Remove 3M tape from cob led strip

Step 5: Put cob led strip into solder-free connectors

Step 6: Light up the led strip to test

2.2 Cut, connect and power IP52 Silicone coating SMD LED strips by solder-free connector

2.3 Cut, connect and power IP65 Silicone tube SMD LED strips by solder-free connector

2.4 Cut, connect and power IP67 Silicone filling SMD LED strips by solder-free connector

FAQs

Yes, you can. But you must cut the LED strip light at the cut line.

Almost all LED strip has a black cut line and scissors mark on the PCB surface.

Yes, Almost all LED strip lights are cuttable. But you must cut the LED strip light at the cut line.

Yes, they can be cut to specific lengths at the cut line. The distance between the cut lines will vary depending on the LED strip lights. 50mm, 25mm are more common in the market.

Yes, you can. But you must cut the LED strip light at the cut line.

Almost all LED strip has a black cut line and scissors mark on the PCB surface.

Yes, you can. But you must cut the LED strip light at the cut line.

Almost all LED strip has a black cut line and scissors mark on the PCB surface.

Yes, you can. But you must cut the LED strip light at the cut line.

Almost all LED strip has a black cut line and scissors mark on the PCB surface.

Yes, you can. But you must cut the LED strip light at the cut line.

Almost all LED strip has a black cut line and scissors mark on the PCB surface.

Yes, you can. But you must cut the LED strip light at the cut line.

Almost all LED strip has a black cut line and scissors mark on the PCB surface.

Yes, you can. But you must cut the LED strip light at the cut line.

Almost all LED strip has a black cut line and scissors mark on the PCB surface.

No, not all LED strip lights are cuttable.

Almost all the LED strip lights are cuttable, and the cuttable LED strip light has a black cut line and scissors mark on the PCB surface.

But some of the few LED strips that do not come with resistors are designed to work with constant current power supplies, and it does not have cut wires and scissor marks. These LED strips are not cuttable.

No, you must cut the LED strip light at the cut line. Otherwise, some parts LED strip will not work anymore.

Yes, but you must cut the LED strip light at the cut line.

Cut LED strip lights at the cut line. Sometimes the cut line has a scissors mark.

Cut LED strip lights at the cut line using just a pair of scissors.

There are two main methods of connecting the LED strip lights.

Method 1: Soldering with a soldering iron.

Method 2: Using solderless connectors.

There are two main methods of connecting the LED strip lights.

Method 1: Soldering with a soldering iron.

Method 2: Using solderless connectors.

You can connect LED strip lights by soldering using a soldering iron.

Step 1: Measure the length

Step 2: Find the cut position on the led strip

Step 3: Cut the led strip light

Step 4: Remove 3M tape from led strip

Step 5: Put led strip into solder-free connectors and close the connectors

Step 6: Light up the led strip to test

For more detail, please check here.

Step 1: Measure the length

Step 2: Find the cut position on the led strip

Step 3: Cut the led strip light

Step 4: Soldering cable to led strip light by electric iron

Step 5: Attached heat shrink tube to protect the soldering point

Step 6: Soldering two-piece led strip together by electric iron

Step 7: Light up the led strip to test

For more detail, please check here.

You can connect LED strip lights by using solderless connectors.

For more detail, please check here.

Step 1: Prepare the soldering tools

Step 2: Cleaning the Soldering Iron

Step 3: Secure the LED strip light

Step 4: Tin the cable and PCB copper pad

Step 5: Soldering the cable to the PCB copper pad

Step 6: Light up the LED strip to check the solder

Step 7: Attached the heat shrink tube to the solder point

Step 8: Light up the LED strip again to check the solder

For more detail, please check here.

Method 1: Multiple LED strip lights connected in parallel to one power supply

Method 2: Middle of a long LED strip light connected to the power supply

Method 3: Use multiple power supplies with various LED strip lights

You need to tangle the wires of the LED strip with the output wires of the LED power supply and wrap them with insulating tape.

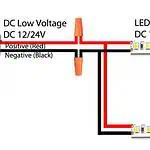

Step 1: Disconnect the LED power supply from the mains

Step 2: Ensure that the output voltage of the LED power supply and the input voltage of the LED strip is the same

Step 3: Connect the output wire of the LED power supply to the wire of the LED strip, and ensure the positive and negative are correctly connected

Step 4: Power on and test

Step 1: Calculate all LED strip lights wattage

Step 2: Find a compatible power supply, make sure the output voltage is the same as the LED strip lights and the 80% wattage is more than the sum wattage of the led strip lights.

Step 3: Connect multiple led strips to the power supply in parallel by hardwiring or splitter.

Conclusion

In conclusion,LED strip lights can provide a great way to add light and ambiance in various spaces. With the proper tools and supplies, anyone can complete the task of cutting and connecting LED strip lights with ease.

LEDYi manufactures high-quality LED strips and LED neon flex. All of our products go through high-tech laboratories to ensure the utmost quality. Besides, we offer customizable options on our LED strips and neon flex. So, for premium LED strip and LED neon flex, contact LEDYi ASAP!