As we all know, there are two test methods mentioned in CIE121: 1966 Clause 6.1, CIE127-2007 Clause 6.2, and IES-LM-79-08 Clause 9.0: One is to use an integrating sphere plus a photometer or a spectroradiometer to test LED luminous flux. The integral method is the relative measurement method of total luminous flux (CIE121: 1966 Clause 6.1.1, CIE127-2007 Clause 6.2.2, and IES-LM-79-08 Clause 9.0). The other is the photometric method using a goniophotometer. This is the absolute measurement method of total luminous flux. If we use the integral approach and the photometric method to test the same lamp, comparing the test results, we will find that the total luminous flux data tested by the two are pretty different. This article focuses on the difference between the lumen test of LED lamps in the integrating sphere and the goniophotometer.

The principle of the integral method to test the total luminous flux is to calibrate the luminous flux standard. Since it is calibrated with a standard lamp, it is not necessary to know the spectral output of the sphere. The luminous flux φTEST (λ) of the tested LED lamp product is calculated by comparing it with the standard lamp. Generally speaking, the integration method is suitable for small integrated LED lamps and relatively small LED light sources to test the total luminous flux and chromaticity parameters. This is the comparative test method of total luminous flux. The integration method has the advantages of fast measurement speed and no darkroom. The smaller the volume, the closer to the point light source, the more accurate the test result.

However, when using the integral method to test larger-sized LED lamps, its limitations are enormous compared with the photometric method. The first method is to use a crucial test fixture, the LED lights face a variety of forms, the LED bare light sources, the spherical LED bulbs, LED lamp, Etc., and the type of LED lamp has a significant influence on the final luminous flux test. At the same time, using the integration method also needs to do the calibration of the integrating sphere. Generally, if you are testing LED lamps, the standard lamp needs to have similar luminous characteristics to the lamp under test, and a stable white LED is the best choice. Of course, other types of lamps can also be used as the calibration light source, but this will affect the calibration accuracy. The second is the difference brought about by the test method: Generally speaking, if the lamp under test is shining to the surroundings, it is necessary to use the 4π test method to install the lamp under test in the center of the integrating sphere (IESLM-79-08 Clause 9.2.5). This kind of test has the best effect. If the lamps are directional lighting, such as LED panel lights, LED street lights, Etc., the lamp under test needs to be installed on the side of the integrating sphere for a 2π test (IESLM-79-08 Clause 9.2.5). 4π integrating sphere for measuring the test method, if the measured power of the lamp or lamp housing occupies the entire large lamp large in size, more or less at the time of testing a self-absorption effect, the need to use this time to make up the auxiliary lamp Error ( IESLM-79-08 Clause 9.1.5). Generally speaking, the integration method is suitable for small integrated LED lamps and relatively small LED light sources. Using the integration method to test such LED lamps can ensure the accuracy and stability of the total luminous flux results, for example, when testing large-size LED lamps. , The limitation of the integral method is relatively large. The reason is, as mentioned above, and the final total luminous flux test has a certain degree of uncertainty.

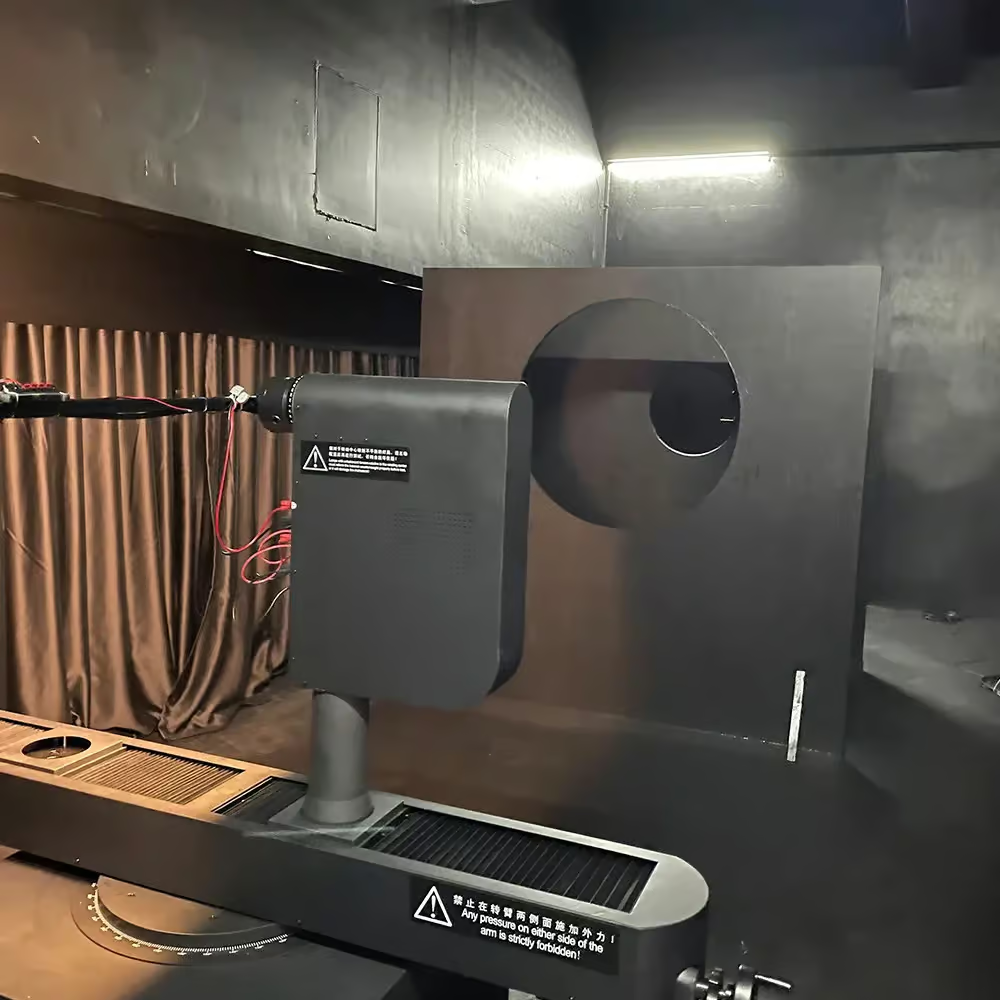

The use of spectrophotometric test Total luminous flux that is distributed photometer, the total luminous flux test rarely limitations. Photometric Test total luminous flux principal amount of a photometer measuring light source is distributed in many different directions of the light source (or light at a given distance from the illumination source) of the light intensity of the device, the light intensity data in each direction To calculate the total luminous flux. Compared with the integral method, due to the difference in the intensity distribution of the test light source, the photometric method has no errors in theory, so it is an absolute test method for the total luminous flux of the LED. It does not require the total luminous flux standard, but it takes a long time for each sample—the measurement time. Adopting the photometric method, the Goniophotometer test will involve Type C Goniophotometer (IES-LM-79-08 Clause 9.3.1, CIE121: 1996 Clause 3.2) darkroom, test distance (IES-LM-79-08 Clause 9.3, CIE121: 1996 Clause 6.2.1.4 ), And so on. The main factors affecting the difference in the total luminous flux output of the goniophotometer are the type of the goniophotometer, the test method (CIE121: 1996 Clause 3.4.2, Clause 3.4.1 and Clause 3.4.3), the test distance, the photometric probe lamps, Etc., according to To test different types of LED products, we can adjust the relevant test methods or equipment; if we encounter LED products with a narrow beam angle, we can choose a small-sized Goniophotometer, choose Type C Goniophotometer, adjust the test distance, and choose a higher level Class L photometric probes can achieve high-precision testing of total luminous flux. In testing the total luminous flux of the LED, the photometric test can achieve the highest precision measurement. Due to the inherent limitations of the integration method, it is difficult to eliminate the error through the adjustment of the equipment, and can only minimize this error. At the same time, the photometric test The required equipment itself is not too limited, so the error can be compensated by improving the modulation and operation of the equipment.

As explained above, one of the easiest ways to measure LED luminous flux is to use an integrating sphere photometer. It is a spatial flux visually integrated setting apparatus. Using a fixed photometer distal to measure the total through- quantity measuring is quick and easy. Use the total luminous flux standard to calibrate the integrating sphere photometer. The test light source is measured by comparison with a standard light source with a similar spatial and spectral distribution. Therefore, this method requires a standard light source calibrated for luminous flux. Compared with the light distribution tester, the test speed is very fast, but when the spatial intensity distribution of the test LED, and the standard light source is not similar, it is easy to produce errors. This type of error is difficult to correct, so it should be through excellent design geometry and similar types of standard LEDs to minimize this error.

As mentioned earlier, the closer the shape of the test fixture is to the point light source, the more accurate the result of the integrating sphere test will be. So when we need to test the lumen value of lamps, for bulb lamps, small LED lamps, integrated LED lamps, lamp tubes, and other lamps with beam angle greater than 180°, we can use an integrating sphere with a spectrometer for 4π testing. For large panel lights, translucent lights, traffic lights, and other lamps with beam angle less than 180°, if you want to use an integrating sphere for testing, you need to use an integrating sphere with side openings for 2π testing or use auxiliary lights for assistance Testing, the testing process is tedious and uncertain. The most accurate test method for this kind of lamp is to use a goniophotometer with a standard darkroom for testing. Can get more accurate luminous flux. However, when the time of the test with a photometer distributed, differences in the test method should be noted that, as the panel lamp is generally used C-γ test, for traffic lights and spotlights generally recommended test B-β; also need a Standard The darkroom requires a more professional test environment and test personnel to operate compared to the integrating sphere test.

In summary, the measuring principles, environment, and test methods of integrating sphere and goniophotometer are different, and the measurement results of the two are not comparable. We can choose a suitable method for testing according to different standards and different requirements.

LEDYi manufactures high-quality LED strips and LED neon flex. All of our products go through high-tech laboratories to ensure the utmost quality. Besides, we offer customizable options on our LED strips and neon flex. So, for premium LED strip and LED neon flex, contact LEDYi ASAP!