Fitilar LED sun fi shahara kuma suna da kyakkyawan zaɓi don hasken kasuwanci, na zama, da masana'antu. Suna da inganci, sauƙin shigarwa kuma suna buƙatar kulawa kaɗan. Kuna iya keɓance filayen LED a cikin siffofi da girma dabam dabam, saboda haka zaku iya amfani da su don haskaka kusan kowane sarari.

Menene Fitilar Tafiyar LED?

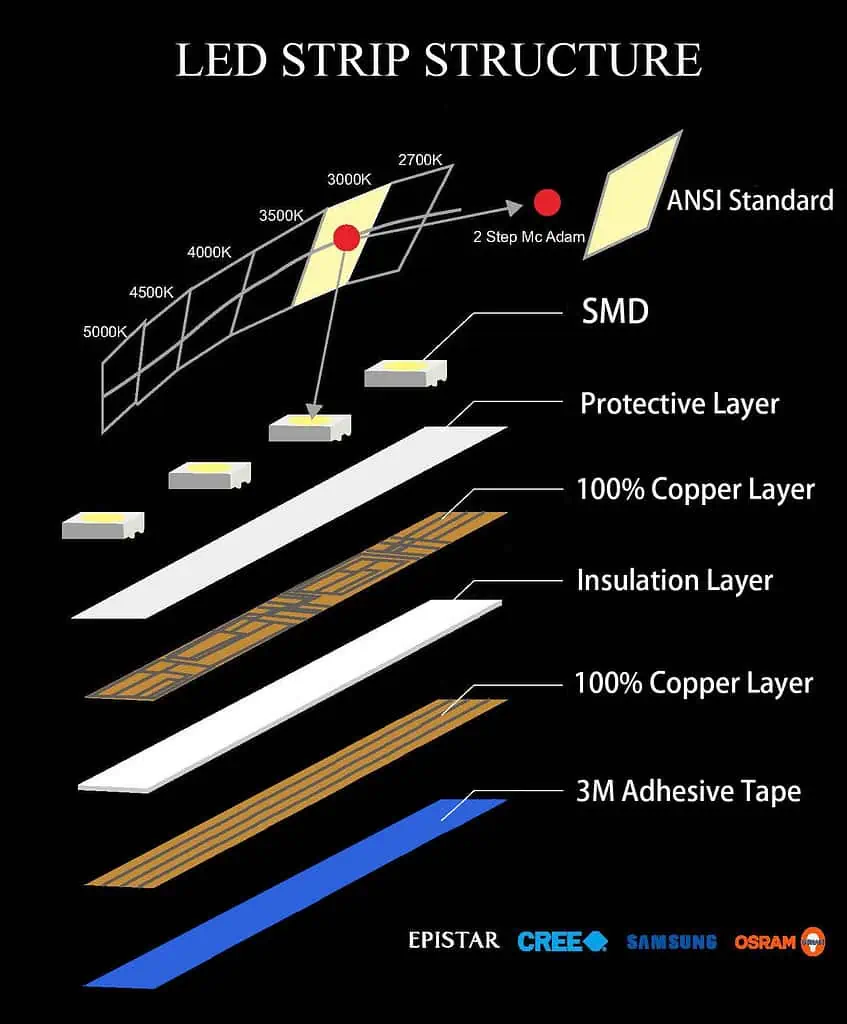

Hasken tsiri na LED (wanda kuma aka sani da tef na LED ko hasken kintinkiri) allon kewayawa mai sassauƙa ne wanda ke cike da diodes masu haskaka haske (SMD LEDs) da sauran abubuwan da galibi ke zuwa tare da goyan bayan m.

Siffofin LED tube:

m

Filayen LED suna da cikakkiyar sassauƙa kuma ana iya lanƙwasa su a tsaye har zuwa digiri 90. Kuna iya amfani da su don haskaka wurare har ma da kunsa su a kusa da siffofi daban-daban.

Zaɓuɓɓuka masu launi

Ana samun tube na LED cikin launuka daban-daban, kamar monochrome, Tunable White, RGB, RGBW, RGBTW, Canjin launi na dijital.

Girman Da Ya Dace

LED tube za a iya yanke zuwa kowane tsawon da kuke bukata.

Kuna iya tsara aikin ku ba tare da damuwa game da tsayin tsiri na LED ba.

Mai sauƙin shigarwa

Bayan ɗigon LED ɗin yana da tef mai gefe biyu na 3M, zaka iya liƙa igiyar LED cikin sauƙi zuwa inda kake buƙata.

Cikakken Dimmable

Fitilar LED tana goyan bayan hanyoyi iri-iri na dimming, kamar PWM, 0-10V, DALI, DMX512, TRIAC dimming.

Tsawon rayuwa

Fitilar LED tana da tsawon rayuwa har zuwa awanni 54,000.

customizable

Za mu iya keɓance filayen jagora na musamman don ayyukanku, kamar launuka na al'ada, CRI, ƙarfin lantarki, haske, faɗi, tsayi, da ƙari.

Gabaɗaya, filayen LED an kasu kashi-kashi kamar haka:

Tsayayyen fari da launi ɗaya

Ja, kore, blue, rawaya, ruwan hoda, ultraviolet, infrared da farin launi tare da CCT daban-daban daga 2100K zuwa 6500K

Farar fata

Akwai LED masu zafin jiki na launi daban-daban guda 2 akan Teburin Tunable White LED. Ta amfani da mai sarrafawa, kuma za'a iya canza launi na ɗigon jagora mai sauƙi daga fari mai dumi zuwa farin haske.

Canjin launi na RGB

Akwai tashoshi uku, zaku iya sarrafa tsiri na jagorar RGB don ƙirƙirar kowane launi da kuke so.

Canjin launi na RGB + W

Akwai tashoshi huɗu, kama da raƙuman jagoran RGB, amma tare da ƙarin farin launi guda ɗaya.

RGB+ Mai canza launin fari mai canzawa

Akwai tashoshi guda biyar, masu kama da RGBW led strip, amma tare da ƙarin farin ko farin launi guda ɗaya.

Canjin Dijital ko Pixel Color

Gilashin jagoran dijital yana ba ku damar samun launuka daban-daban ga kowane sashe na tsiri na LED, ƙirƙirar launuka daban-daban a sassa daban-daban na tsiri ɗaya na LED.

Tsarin Kera Fitilar Fitilar LED

Mataki 1: LED Lamp Production

Mataki na 2: Ƙirƙiri kuma Yi Amfani da Motocin Solder

Mataki 3: Aiwatar da Manna Solder mara gubar akan PCB Base

Mataki na 4: Sanya sassa

Mataki na 5: Sake Sayar da Sayar

Mataki 6: Ware da Weld da 0.5m LED Strip Segments Tare

Mataki na 7: tsufa da hana ruwa

Mataki 8: 3M Tape Pasting da Packaging

Babban abubuwan da ke cikin fitilun LED sune LEDs, FPCB (Plexible Printed Circuit Boards), resistors ko wasu abubuwan da aka gyara. Ana kera filayen LED ta hanyar amfani da tsari mai suna Surface Mount Technology (SMT) Tsarin Majalisar don hawa LEDs, resistors da sauran abubuwa akan FPCB.

Amfani da tsarin PCBA, za mu iya zahiri keɓance filayen LED ɗinku a matakin PCB don saduwa da takamaiman buƙatun hasken ku. Hakanan muna gudanar da gwajin sarrafa inganci a ƙarshen kowane mataki don tabbatar da samfuranmu sun kai daidai. Bari mu dubi yadda wannan tsari yake aiki.

Mataki 1: LED Lamp Production

Mataki na farko shine samar da fitilun LED, wanda ake kira Encapsulation LED.

Fitilar LED sune mafi mahimmancin bangaren, ƙayyade ingancin tsiri na LED. Shi ya sa ba ma samar da fitilun LED kamar sauran masana'antu. Muna kera fitilun LED na mu don tabbatar da ingancin fitilun LED ɗin mu. Bari mu dubi yadda ake samar da fitilun LED.

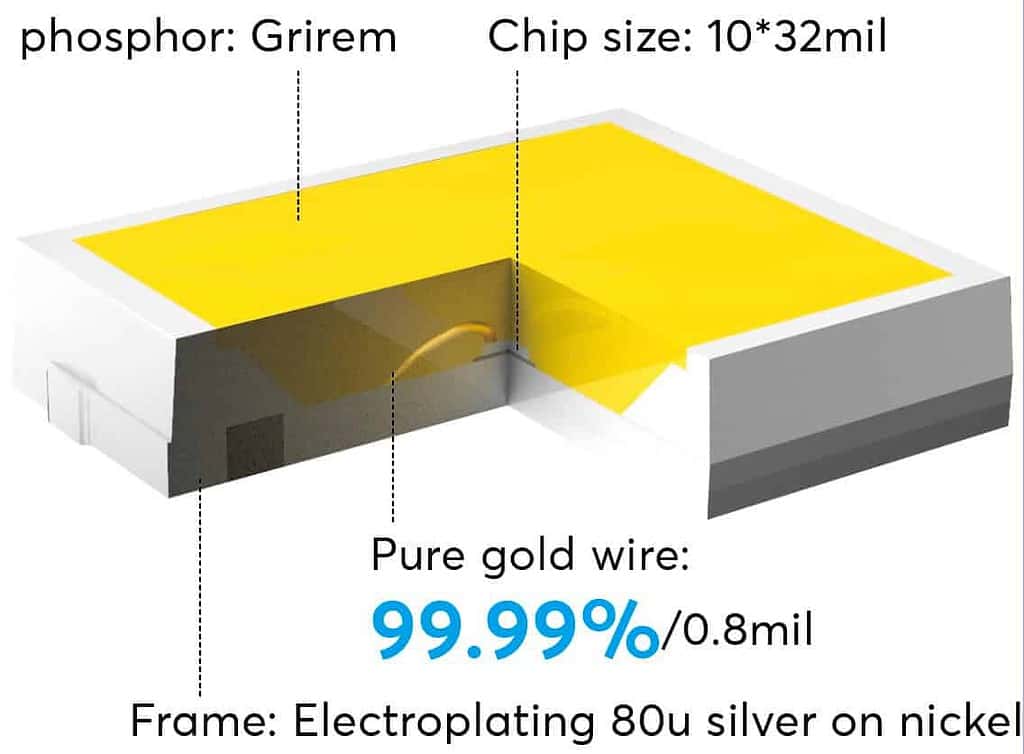

Mataki 1.1: Mutuwar abin da aka makala

Die abin da aka makala wani tsari ne wanda ke haɗa guntu zuwa wurin da aka keɓance na firam ta hanyar colloid (manne gabaɗaya manne ko insulating manne don LED) don samar da hanyar thermal ko hanyar lantarki, wanda ke ba da yanayi don haɗin haɗin waya na gaba. Muna amfani da kwakwalwan kwamfuta daga manyan kayayyaki masu inganci, kamar Epistar, Sanan, da sauransu.

Mataki 1.2: Waya Bonding

Haɗin waya shine tsarin ƙirƙirar haɗin wutar lantarki tsakanin firam ɗin jagora da kwakwalwan kwamfuta ta hanyar amfani da wayoyi masu haɗawa, waɗanda aka yi da zinari 99.99%.

Mataki 1.3: Rarraba Silicone Phosphor

Yawancin LEDs a kasuwa sun dogara ne akan kwakwalwan LED masu fitar da shuɗi tare da phosphor da aka ƙara don cimma farin haske mai hade.

Domin samun madaidaicin zafin launi, muna buƙatar daidaita daidaitaccen rabo na phosphor. Sannan ana hada foda da silica gel din da ake hadawa daidai gwargwado, sannan a hada phosphor foda silica gel cakuda a saman braket na LED don rufe guntuwar LED. Wannan mataki yana da matukar muhimmanci. Yawancin fitilun LED suna da matsala saboda an katse wayar zinare, sannan na yanzu ba zai iya wucewa tsakanin guntu na LED da maƙallan LED ba, wanda ke sa fitilun LED ɗin ba su iya yin haske.

Mataki 1.4: Yin burodi

Bayan Dispensing Phosphor Silicone, fitilar LED tana buƙatar gasa a cikin tanda don bushe danshin foda na phosphor.

Mataki 1.5: Rarraba

Za'a iya gwada fakitin LEDs da kuma jerawa bisa ga tsayin raƙuman ruwa, daidaitawar Chromaticity x, y, ƙarfin haske, kusurwar haske, da ƙarfin aiki. A sakamakon haka, LEDs sun kasu kashi-kashi na bins da nau'i-nau'i, sa'an nan kuma na'urar tantancewa ta atomatik ta tattara ledojin zuwa cikin kwanoni daban-daban bisa ga ka'idodin gwajin. Yayin da bukatun mutane na LEDs ke karuwa, na'urar tantancewar farko ita ce 32Bin, wanda daga baya ya karu zuwa 64Bin, kuma yanzu akwai na'urori masu rarraba 72Bin na kasuwanci. Duk da haka, ma'aunin fasaha na LED na Bin har yanzu ba zai iya biyan bukatun samarwa da kasuwa ba.

Don LED masu launi masu launi, kamfaninmu yana ɗaukar madaidaicin madaidaicin, 3-mataki McAdam, don warware LEDs. Wannan yana nufin cewa daidaiton launin mu yana da kyau sosai cewa ido ba shi da hanyar ganin bambanci.

Mataki 1.6: Tap

Kafin a faki LED ɗin, ana buƙatar gano LED ɗin, daidaitacce, da kuma kunshe a cikin tef. Ana iya ba da LEDs ɗin da aka kaɗe zuwa na'urorin sanyawa na SMT a babban gudun don jeri hukumar da'ira.

Mataki 1.7: Kunshin

Bayan tapping, LED fitilar za a kunshin ta nadi. Ana saka kowane nadi a cikin jakar foil na allumini mai jujjuyawa, sannan a kwashe a rufe.

Mataki na 2: Ƙirƙiri kuma Yi Amfani da Motocin Solder

Bakin karfe molds an halicci kowane tsiri haske zane. Ramuka ne da ke saman PCB maras tushe domin manna mai siyar ya bazu daidai kan wurin siyar.

Mataki 3: Aiwatar da Manna Solder mara gubar akan PCB Base

Yawancin igiyoyi da ba a haɗa su ba na PCB, tsayin mita 0.5, sun haɗa da "tabashin PCB". Ana sanya shi a ƙarƙashin ƙirar kuma manna mai siyar da ba ta da gubar ta cika ramukan da ke cikin ƙirar daidai, yana haifar da fatun marasa lahani.

Gwaran Gwaji

Matakin QC yana tabbatar da cewa kowane madaidaicin siyar yana da madaidaicin adadin manna mai siyarwa kuma an shirya shi don abubuwan da za'a sanya su akan wuraren siyar.

Mataki na 4: Sanya sassa

Bayan haka, ana sanya takardar PCB cikin injin sanyawa na SMT. Wannan injin yana ɗauka yana sanya masu tsayayya, LEDs da sauran abubuwan da aka gyara akan wuraren siyar tare da cikakkiyar daidaito da matsa lamba.

Muna amfani da injunan SMT na Jafananci mai saurin sauri don taimaka mana kula da inganci mai kyau.

Gwaran Gwaji

Ana sake duba PCB tare da duk abubuwan da aka haɗe ta hanyar sarrafa inganci. Idan akwai ɓangaren da ba daidai ba, ana lura da shi kuma za a sake yin aikin takardar PCB har sai ta wuce dubawa.

Mataki na 5: Sake Sayar da Sayar

Ba za a gyara abubuwan da aka gyara akan PCB ba har sai manna mai siyar ya taurare. Don yin wannan, ana ɗaure allon PCB a cikin tanda mai juyawa. Tanda mai sake fitarwa doguwar tanda ce mai yankuna da yawa inda za'a iya sarrafa zafin jiki da kansa yayin da PCB ke wucewa.

Gwaran Gwaji

Bayan takardar LED ta fito daga reflow soldering, za mu yi wani ingancin dubawa a nan. Haskaka takardar LED don tabbatar da cewa duk LEDs na iya yin haske akai-akai. Fitilolin LED waɗanda aka ƙi ana sake yin su ko kuma ana sayar da su da hannu har sai sun cika.

Mataki 6: Ware da Weld da 0.5m LED Strip Segments Tare

Fayil ɗin PCB na 0.5m (wanda ya ƙunshi ɗimbin ɓangarorin jagororin da aka haɗe) an ware su kuma ana sayar da su daga ƙarshe zuwa ƙarshen har sai sun cimma ƙayyadaddun tsayi.

Gabaɗaya, za mu siyar da ɓangaren PCB zuwa mitoci na mita 5.

Gwaran Gwaji

Lokacin da muka sayar da PCB a cikin nadi mai tsayi, za mu sake duba duk wuraren sayar da kayan don tabbatar da cewa ana iya kunna fitilun LED gabaɗaya.

Mataki na 7: tsufa da hana ruwa

Za a sanya filayen LED ɗin da aka welded a cikin ɗakin gwajin tsufa, ana ci gaba da haskakawa, kuma za su yi aiki na sa'o'i 12. Muna kiran wannan mataki gwajin ƙonawa. Wannan gwajin zai iya taimaka mana mu gano ingantattun matsalolin filayen LED gwargwadon yiwuwa kafin jigilar kaya.

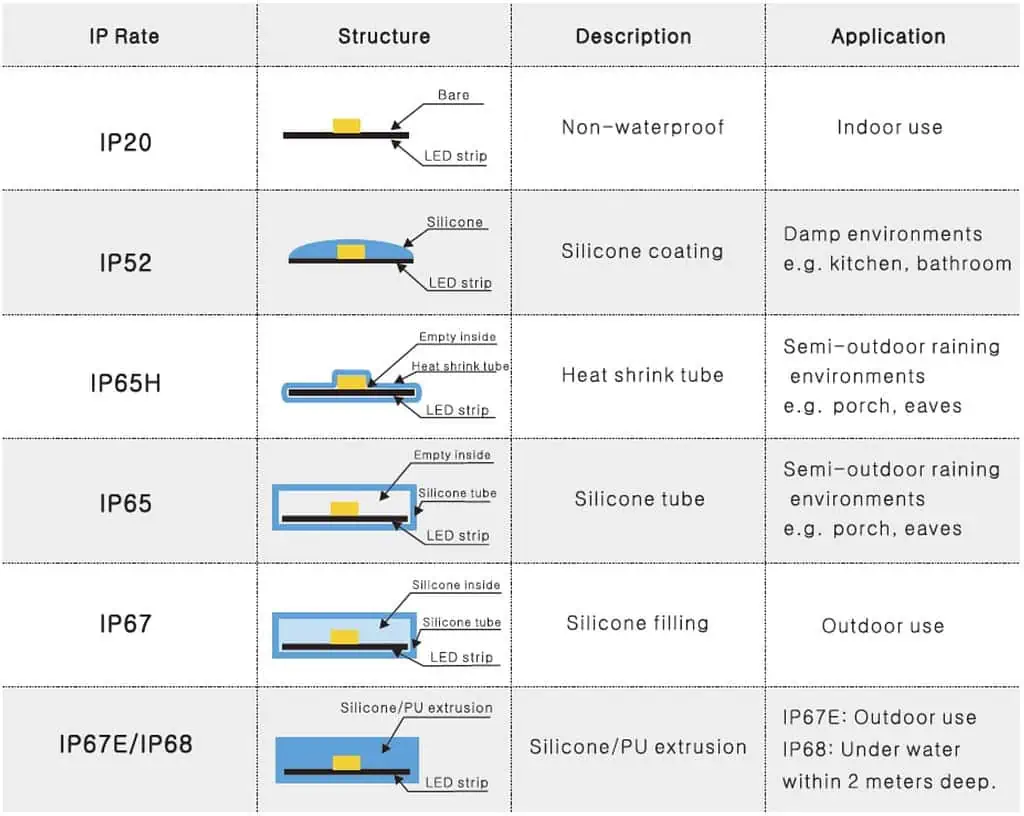

Idan ana buƙatar amfani da wasu filaye na LED a waje ko ƙarƙashin ruwa, kuma suna buƙatar zama mai hana ruwa da ƙura.

Muna ba da maki mai hana ruwa da ƙura don abokan ciniki su zaɓa.

IP20: Bare, mara ruwa, amfani na cikin gida, don wuraren bushewa.

IP52: Silicone shafi, na cikin gida amfani, don damp yanayi.

IP65: Silicone tube / Heat shrin tube, don amfani da waje na waje, don yanayin ruwan sama

IP67: Silicone tube da silicone cika ko m silicone extrusion, amfani waje

IP68: PU (Polyurethane), amfani a karkashin ruwa.

Mataki 8: 3M Tape Pasting da Packaging

Da zarar tsiri na LED ya wuce binciken, za mu sanya tef mai gefe biyu na 3M a bayan tsiri na LED. Wannan yana sauƙaƙa wa abokan ciniki don shigar da ɗigon LED, kawai yaga tef ɗin mai gefe biyu na 3M kuma su manne shi a inda suke so.

Tabbatar yin amfani da tef mai gefe biyu mai inganci na 3M, wanda ba wai kawai yana tabbatar da ƙarfi mai ƙarfi ba, har ma yana ƙara haɓaka zafi kuma yana tsawaita rayuwar tsiri na LED.

Za a jujjuya kowane tsiri na LED a kan reel, sannan kowane nadi za a sanya shi a cikin jakar foil na aluminium anti-static. Sa'an nan kuma manne tambarin zuwa jakar foil na aluminum anti-static. Kuma kusan jakunkuna 50 ana cushe cikin akwati daya.

Gwajin Inganci:

Gwajin ingancin mu na ƙarshe shine binciken bazuwar filayen LED da aka shirya don marufi. Wannan yana taimaka mana mu kula da ingancin inganci.

Abubuwan da ke shafar ingancin fitilun fitilun LED

1. ingancin FPCB

High quality, 2-4 oz ninki biyu-Layer tagulla m PCBs tabbatar da santsi nassi na babban halin yanzu, rage zafi tsara da kuma taimaka zafi ya bace da sauri. Zafi na iya yin tasiri a kan rage rayuwar LEDs, don haka muna buƙatar nemo hanyoyin da za mu watsar da shi. Ta hanyar haɗa tsiri na LED zuwa bayanin martaba na aluminum za mu iya watsar da zafi mai yawa kamar yadda zai yiwu kuma rage zafin aiki.

2. Ingancin SMD LEDs

Brand LED kwakwalwan kwamfuta kunshe da mafi ingancin thermal pads, mutu bond kayan, phosphor, da 99.99% zinariya bond wayoyi.

Gwaji mai tsauri tare da rahoton LM-80 da TM-21.

Babban haske, Babban CRI, Gamut Index, Fidelity Index, da Saturation

Tabbatar cewa BINs suna da daidaiton launi mai kyau, a cikin Macadam mataki 3

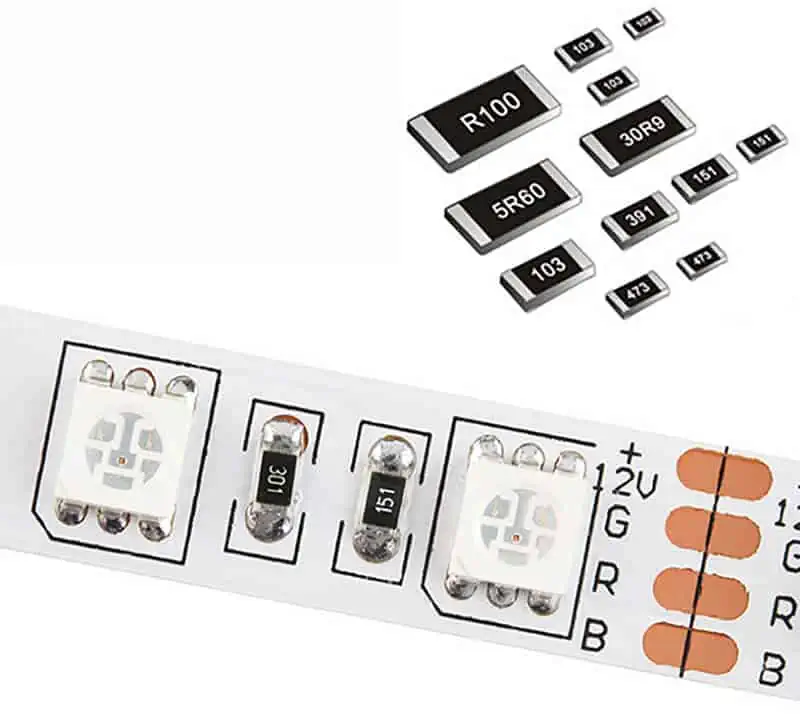

3. Quality na Resistors

Ana amfani da resistors don daidaita halin yanzu na gaba ta hanyar LEDs domin LEDs suyi aiki a hasken da aka tsara. Darajar resistor na iya canzawa daga tsari zuwa tsari. Yi amfani da kamfani mai suna don resistors.

Da fatan za a tabbatar cewa kuna amfani da resistors masu inganci. Ƙananan resistors na iya rage rayuwar fitilun LED ko ma lalata shi.

Kada ku rinjayi LEDs! Za su yi haske da farko amma za su yi kasa da sauri. Mun san kaɗan daga cikin masu fafatawa da wannan. Zafin da ya wuce kima na iya zama haɗari idan an sanya shi akan kayan wuta.

4. Ingancin waya da masu haɗawa

Koyaushe zaɓi abubuwan da aka gwada don aminci da dorewa.

5. Kyakkyawan Tef 3M

Muna amfani da alamar 3M 300LSE ko tef VHB. Yawancin masu samar da kayayyaki suna ba da wani suna ko mafi muni, manne sunan alamar karya. Makullin shigarwa na dindindin mai dorewa da ƙarfin zafin jiki shine babban tef ɗin inganci.

6. Sanya sassa

Hakanan yana da mahimmanci don tabbatar da cewa duk abubuwan da aka gyara suna daidai kuma an sayar dasu cikin aminci ga PCB.

LED tubes wani lokacin ba sa aiki yadda ya kamata saboda mugun soldering.

Kammalawa

High quality LED tube iya zama mafi tsada. Koyaya, saboda ƙarancin gazawar, manyan filayen LED masu inganci suna buƙatar ƙarancin kulawa. Kamar yadda farashin aiki ya fi girma fiye da farashin samfurin, zai zama mafi tasiri don zaɓar tsiri mai inganci na LED. Yana da kyau koyaushe ka yi bincikenka kafin yanke shawarar siye. Idan kuna son ƙarin sani game da tube LED ko kuna da wasu tambayoyi, jin daɗin yin sharhi. Manufarmu ita ce samar da ingantattun hanyoyin samar da hasken wuta na LED wanda zai daɗe ku har tsawon shekaru!

LEDYi yana kera inganci mai inganci LED tube da LED neon flex. Duk samfuranmu suna tafiya ta cikin dakunan gwaje-gwaje masu fasaha don tabbatar da mafi kyawun inganci. Bayan haka, muna ba da zaɓuɓɓukan da za a iya daidaita su akan filayen LED ɗinmu da lanƙwasa neon. Don haka, don ɗigon LED mai ƙima da LED neon flex, lamba LEDY ASAP!