Isizathu sokuba kwenziwe iisekethe eziguquguqukayo eziprintiweyo yayikukususa imfuneko yeentambo zokubopha eziqinileyo. Iisekethe eziprintiweyo eziguquguqukayo zisetyenziswa phantse kuwo onke amashishini ngenxa yokunxibelelana, ukuhamba, ukunxiba, ukucutheka, kunye nezinye iindlela zale mihla. Kwisiseko sayo esisisiseko, isekethe eguquguqukayo yenziwe ngabaqhubi abaninzi abahlulwe yifilimu ye-dielectric ebuthathaka. Iibhodi zeesekethe eziprintiweyo eziguquguqukayo zingasetyenziselwa yonke into ukusuka kwizinto ezilula ukuya kwimisebenzi enzima kakhulu.

Imbali yeFPCB

Ekuqaleni kwenkulungwane yama-20, abaphandi kwishishini elitsha leefowuni babona imfuneko yeesekethe zombane eziqhelekileyo nezibhetyebhetye. Iisekethe zenziwe ngamaleko atshintshanayo ee-conductor kunye ne-insulators. Ngokwe-patent yesiNgesi ka-1903, iisekethe zenziwe ngokubeka iparafini ephepheni kunye nokubeka iikhondaktha zentsimbi ezicaba. Kumanqaku akhe avela ngexesha elifanayo, uThomas Edison ucebise ukuba kusetyenziswe iphepha lelinen elifakwe nge-cellulose gum kwaye lizotywe nge-graphite powder. Ngasekupheleni koo-1940, xa ubuchule bemveliso yobuninzi babuqala ukusetyenziswa, amalungelo awodwa omenzi wechiza amaninzi afakwa kwiisekethe zefoto-etching kwi substrates eziguquguqukayo. Ukongeza amacandelo asebenzayo kunye ne-passive kwiisekethe eziguquguqukayo ezikhokelela kuphuhliso "lweteknoloji ye-silicon eguquguqukayo, echaza ukukwazi ukudibanisa i-semiconductors (usebenzisa iteknoloji efana ne-transistors yefilimu encinci) kwi-substrate eguquguqukayo. Enkosi ngokudityaniswa kwe-onboard computation kunye nomthamo wenzwa, kuye kwakho uphuhliso olutsha oluchulumancisayo kwimimandla emininzi enezibonelelo eziqhelekileyo zoyilo lwesekethe eguquguqukayo. Uphuhliso olutsha, ngakumbi kwinqwelomoya, amayeza, kunye nombane wabathengi.

Yintoni iFPCB?

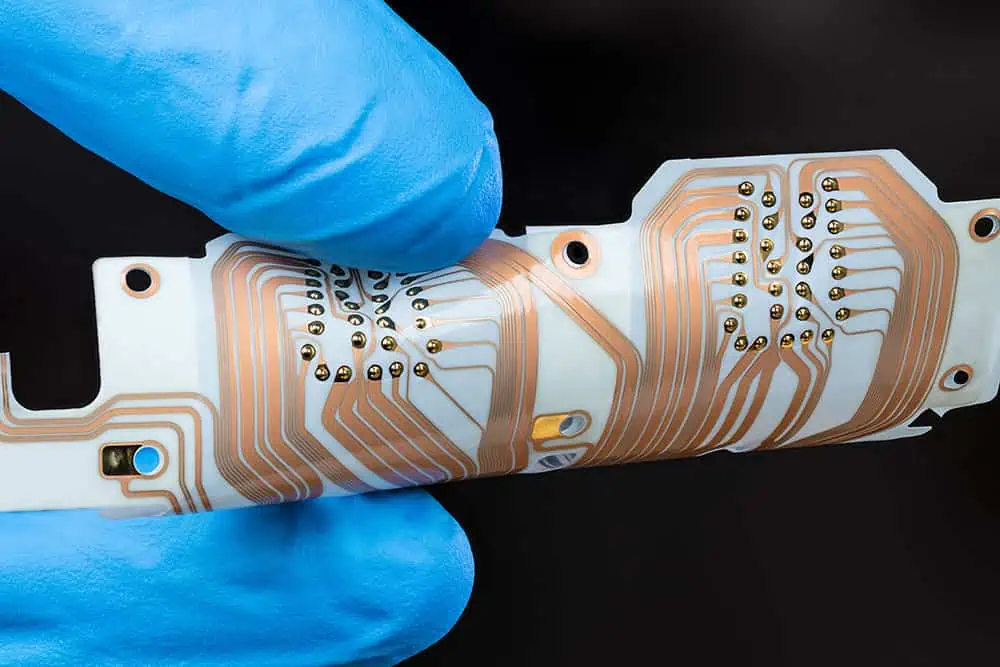

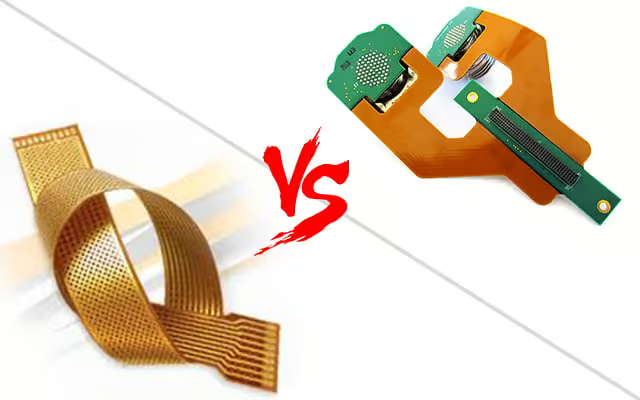

Njengoko kuthelekiswa rhoqo PCB, kukho umahluko ophawulekayo kwindlela eziyilwe ngayo, ezenziweyo nendlela ezisebenza ngayo. Akuchanekanga ukuthi iindlela zale mihla zokwenza “ziprintiwe.”Ekubeni umfanekiso wefoto okanye i-laser imaging isetyenziswa ngakumbi nangakumbi ukuchaza iipateni endaweni yokushicilela, umaleko wemikhondo yesinyithi uncanyathiselwa kwisixhobo sombane esifana ne-polyimide ukwenza isekethe eprintiweyo ethambileyo. . Ubukhulu bomaleko we-dielectric bunokuvela kwi-.0005 intshi ukuya kwi-intshi ze-010. Ngelixa ubukhulu bomaleko wesinyithi bunokuba naphi na ukusuka kwi-intshi ze-.0001 ukuya ku->.010 intshi. Ukunamathiswa rhoqo kuqhotyoshela isinyithi kwii-substrates zazo, kodwa ezinye iindlela, ezifana nokubeka umphunga, nazo zinokwenzeka. I-Copper inokuthi i-oxidize, ngoko idla ngokugqunywa ngoluhlu olukhuselayo. Igolide okanye i-solder yizona zikhetho eziqhelekileyo kuba ziqhuba umbane kwaye ziyakwazi ukumelana nokusingqongileyo. Isixhobo se-dielectric sihlala sisetyenziselwa ukugcina i-circuitry kwi-oxidizing okanye imfutshane kwiindawo apho ingachukumisi nantoni na.

Ubume beFPCB

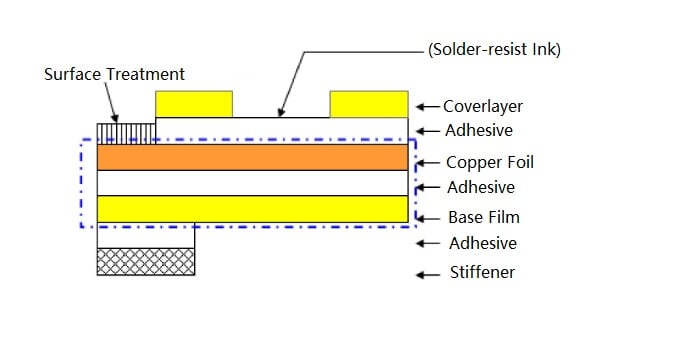

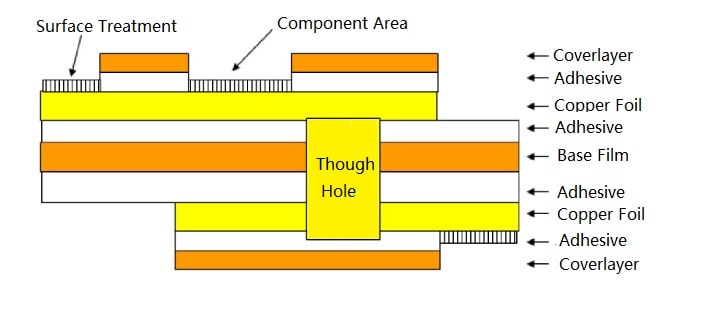

IiPCB eziguquguqukayo zinokuba nenye, ezimbini, okanye ngaphezulu zeeleya zesekethe, njengeePCB eziqinileyo. Uninzi lweesekethe eziprintiweyo ezinomgangatho omnye zenziwe ngala malungu:

- Ifilimu ye-dielectric substrate isebenza njengesiseko sePCB. Eyona nto isetyenzisiweyo, i-polyamide (PI), inokuchasana okunamandla kwi-traction kunye nobushushu.

- Ii-conductor zombane ezisekelwe kubhedu ezisebenza njengemikhondo yesekethe

- Ingubo yokukhusela yenziwe ngokusebenzisa i-cover cover okanye i-coat coat.

- I-polyethylene okanye i-epoxy resin yinto encamathelayo ebamba amacandelo ahlukeneyo esekethe kunye.

Okokuqala, ubhedu lufakwe ukuveza umkhondo, kwaye emva koko isigqubuthelo esikhuselayo (i-cover cover) sihlatywa ukuze siveze iipads zokuthambisa. Amalungu ayacocwa aze asongwe kunye ukwenza imveliso yokugqibela. Izikhonkwane kunye neetheminali ezingaphandle kwesekethe zifakwe kwi-tin ukuze zincede ngokudibanisa okanye zigcinwe zingavuthwa. Ukuba isiphaluka sinzima okanye sifuna izihlangu zomhlaba zobhedu, ukutshintshela kwi-double-layer okanye i-multi-layer FPC ibalulekile. Ii-FPC ezinomaleko amaninzi zenziwe ngendlela efanayo kwii-FPC zomaleko omnye. Kodwa, kwii-FPCs ze-multi-layer, i-PTH (iPlated through Hole) kufuneka yongezwe ukudibanisa iileya zokuqhuba. Izinto zokubambelela zinamathele kwiindlela zokuqhuba kwi-substrate ye-dielectric okanye, kwiisekethe ezininzi eziguquguqukayo, zinamathele amanqwanqwa ahlukeneyo ukuze enze isiphaluka. Ngaphandle koko, ifilimu enamathelayo inokukhusela isiphaluka esiguquguqukayo kumonakalo obangelwa ngumswakama, uthuli kunye nezinye iinqununu.

Inkqubo yokuVeliswa kweFPCB

Ukubanjwa kweSchematic, ibhodi yesekethe eprintiweyo, kunye nokwakhiwa kwebhodi yesekethe kunye nendibano yinkcazo yezinga eliphezulu lamanyathelo ekuyileni kunye nokwenza i-PCB, kodwa iinkcukacha zinzima. Kweli candelo, siza kujonga inyathelo ngalinye.

- Yakha iSkimu

Phambi kokuba uqalise ukuyila ibhodi ngezixhobo zeCAD, kubalulekile ukugqiba ukuyila amacandelo ethala leencwadi. Oku kuthetha ukwenza iisimboli ezinengqiqo zeendawo onokuzakha, njengezixhasi, ii-capacitors, ii-inductors, uqhagamshelo, kunye nee-ICs. Onokuthi usebenzise kwi-schematic (ICs). Nje ukuba la macandelo elungile, ungaqala ngokuwabeka ngolungelelwano kumaphepha eskimu usebenzisa izixhobo zeCAD. Nje ukuba iziqwenga zidityaniswe ngokudibeneyo, unokuzoba iingcingo ukubonisa indlela izikhonkwane zeempawu zesikimu ezinxibelelana ngayo. Kwimemori ye-elektroniki kunye neesekethe zedatha, iinetha yimizila ebonisa inetha enye okanye amaqela einetha. Ngexesha lokubanjwa kweskimu, kufuneka uhambise iindawo zenkqubo ngeenxa zonke ukwenza umzobo ocacileyo nofundekayo.

- Ukulinganisa kweSekethe

Nje ukuba uzobe iinxalenye zesikimu kunye noqhagamshelo, unokuvavanya isekethe ukuze ubone ukuba iyasebenza na. Unokuphinda uhlolisise oku ngokusebenzisa i-SPICE (iNkqubo yokuLingisa ngokuQiniswa kweSekethe eDityanisiweyo) ukulinganisa kweesekethe kwiprogram yokulinganisa. Phambi kokwenza eyona hardware, iinjineli zePCB zinokusebenzisa ezi zixhobo ukulinganisa iisekethe eziye zayila. Izixhobo zoyilo zePCB zibalulekile kuba zinokugcina ixesha nemali.

- CAD Tool Setup

Ngezixhobo zoyilo lwanamhlanje, abaqulunqi bePCB banokufikelela kwiifitsha ezininzi, njengokukwazi ukuseta imithetho yoyilo kunye nemiqobo. Oko kugcina inetha nganye ekuweleni kwaye inika indawo eyaneleyo phakathi kwamalungu. Abaqulunqi nabo banokufikelela kuluhlu olubanzi lwezixhobo ezongezelelweyo. Izixhobo ezifana neegridi zoyilo. Kwenza kube lula ukubeka amacandelo kunye neendlela zokulandelela ngendlela ehlelekile.

- Amacandelo oYilo

Emva kokuba wenze i-database yoyilo kunye nedatha ye-schematic malunga nendlela i-nets edibanisa ngayo ithunyelwa ngaphandle, unokwenza ibhodi yebhodi yesekethe eyiyo. Okokuqala, kuya kufuneka ubeke imilenze yecandelo ngaphakathi kwebhodi yolwandlalo kwinkqubo yeCAD xa umyili ecofa umfanekiso. Umzobo "we-ghost-line" obonisa uqhagamshelo lomnatha kunye nezixhobo ezikhokelela kuzo eziza kuvela. Ngokuziqhelanisa, abaqulunqi baya kufunda indlela yokubeka la malungu ukuze asebenze kakuhle-ukuqwalasela izinto ezinjengokuqhagamshelwa, iindawo ezishushu, ingxolo yombane, kunye nezithintelo zomzimba ezifana neentambo, izihlanganisi, kunye ne-hardware yokunyuka. Abaqulunqi abanakucinga malunga noko kufuneka isekethe. Abaqulunqi kufuneka bacinge malunga nokuba bawabeka phi amalungu ukuze kube lula ukuba umenzi adibanise.

- PCB Umzila

Ngoku ukuba yonke into ilapho kufanele ukuba ibe khona, ungadibanisa iminatha. Ukwenza oku, kufuneka wenze imigca kunye neenqwelomoya kumzobo ovela kwiidibaniso kwi-rubber-band net. Iinkqubo zeCAD zineefitsha ezininzi eziluncedo, ezinje ngemisebenzi yomzila ngokuzenzekelayo esika ixesha loyilo, elibanceda ukuba benze oku.

Kubalulekile ukuhoya kakhulu indlela. Kuyimfuneko ukuqinisekisa ukuba ubude beminatha buzilungele iimpawu abaziphetheyo kwaye azihambi kwiindawo ezinengxolo eninzi. Ngenxa yoku, ukuthetha-thethana kunye nezinye iingxaki kunye nokuthembeka komqondiso kunokuchaphazela indlela ibhodi esebenza ngayo emva kokuba yenziwe.

- Misela i-PCB ecacileyo yokuBuyisa indlela yangoku.

Kufuneka udibanise awona macandelo asebenzayo ebhodini, njengeesekethe ezidibeneyo (ICs), kumandla kunye nenetha yomhlaba. Konke okufuneka ukwenze ukwenza iinqwelomoya eziqinileyo ezinokuthi ezi ndawo zifikelele kuzo kukukhukhula indawo okanye umaleko. Xa kuziwa ekwenzeni amandla kunye neenqwelomoya zomhlaba, izinto zinzima ngakumbi. La maphiko nawo anomsebenzi obalulekileyo wokuthumela imiqondiso emva komkhondo. Ukuba iinqwelomoya zinemingxuma emininzi kakhulu, ukusika, okanye ukwahlula, iindlela zokubuya zingangxola kakhulu kwaye zilimaza ukusebenza kwePCB.

- Ukujongwa kokugqibela kweMithetho

Uyilo lwePCB yakho seluphantse lwenziwa ngoku ukuba ugqibile ukubeka izinto, umkhondo wendlela, kunye nokwenza amandla kunye neenqwelomoya zomhlaba. Isinyathelo esilandelayo kukuseta okubhaliweyo kunye nokumakishwa okuza kukrolwa isilika kumaleko angaphandle kwaye kuqhutywe ukuhlolwa kwemithetho yokugqibela.

Ukubeka amagama, imihla, kunye nolwazi lwelungelo lokushicilela ebhodini kuya kunceda abanye bafumane iindawo. Kwangaxeshanye, kufuneka wenze kwaye usebenzise imizobo yokuvelisa ekudaleni nasekuhlanganiseni iiPCB. Abaqulunqi bePCB basebenzisa izixhobo ezibanceda babone ukuba kuya kubiza malini ukwenza ibhodi.

- Yenza iBhodi

Emva kokuba udale iifayile zedatha yemveliso, inyathelo elilandelayo kukuzithumela kwindawo yokuvelisa ukwenza ibhodi. Emva kokuba unqumle umkhondo kunye neenqwelomoya kwiingqimba zetsimbi, Kufuneka uzicinezele kunye ukuze wenze "ibhodi engenanto" ekulungele ukuhlanganiswa. Xa ibhodi ifika apho ungayifaka khona, Ungayinika iindawo eziyifunayo. Emva koko, ungayifaka enye yeenkqubo ezininzi zokuthengisela ezenzelwe inxalenye nganye. Ibhodi ekugqibeleni ilungile ngoku njengoko iphumelele zonke iimvavanyo eziyimfuneko.

Izinto ezisetyenziselwa ukwenza iFPCB

Iimveliso zeFPCB azenziwanga nje ngezinto eziguquguqukayo kodwa ziziva zikhaphukhaphu kwaye zibhityile. Isakhiwo sikhaphukhaphu kangangokuba ungasolula amaxesha amaninzi ngaphandle kokulimaza ukufakwa kwi-PCB. Ibhodi ethambileyo ayinakukwazi ukuthwala i-high conduction current okanye i-voltage kuba yenziwe ngeplastiki kwaye yenziwe ngeengcingo. Oku kuyenza ingabi luncedo kakhulu kwiisekethe ze-elektroniki ezinamandla aphezulu. Kodwa ungasebenzisa iibhodi ezithambileyo kakhulu kumandla aphantsi, umbane ophantsi wangoku wabathengi. Iibhodi ezithambileyo azifane zisetyenziswe njengebhodi ephambili yokuthwala kuyilo lwemveliso kuba ixabiso leyunithi liphezulu. Oku kungenxa yokuba izinto eziphambili zePI zilawula ukuba zingaphi iibhodi ezithambileyo ezixabisa iyunithi nganye. Kunoko, baqeshwe ukuba baqhube kuphela iindawo "ezithambileyo" zoyilo olubalulekileyo. Amacandelo e-elektroniki okanye iimodyuli ezisebenzayo ezifuna ukuhamba kunye nokusebenza kufuneka iibhodi zeesekethe ezithambileyo. Umzekelo, i-electron zoom lens kwikhamera yedijithali okanye i-read head electronic circuit kwi-optical disc drive yimizekelo yoku. I-PI, ekwabizwa ngokuba yi-Polyimide (PI), isenokwahlulwa ibe yi-PI enevumba elimnandi kunye ne-semi-aromatic. Ungayisebenzisa ngokusekelwe kwisakhiwo sayo se-molecular kunye nokukwazi ukuphatha ukushisa okuphezulu. I-PI enevumba elipheleleyo yikhompawundi yemichiza eyenye yeentlobo ezithe tye zePI. Izinto zinokuthamba okanye zibe nzima, okanye zibe zombini. Ngenxa yokuba zifakwe, izinto ezinokuthi zitofwe azikwazi ukubunjwa, kodwa zinokutyunyuzwa, zifakwe, kwaye zisetyenziswe ngokwahlukileyo. I-semi-aromatic PI luhlobo lwe-polyetherimide yeli qela. Kuba imathiriyeli iyi-thermoplastic, ukubumba inaliti kudla ngokusetyenziswa ukwenza i-polyetherimide. Nge-Thermosetting PI, ungasebenzisa ukubunjwa kwe-lamination yezixhobo ezifakwe ngaphakathi, ukubunjwa koxinzelelo, kunye nokudlulisa ukubumba, okudinga iimpawu ezahlukeneyo kwizinto eziluhlaza.

Iintlobo zeFPCB

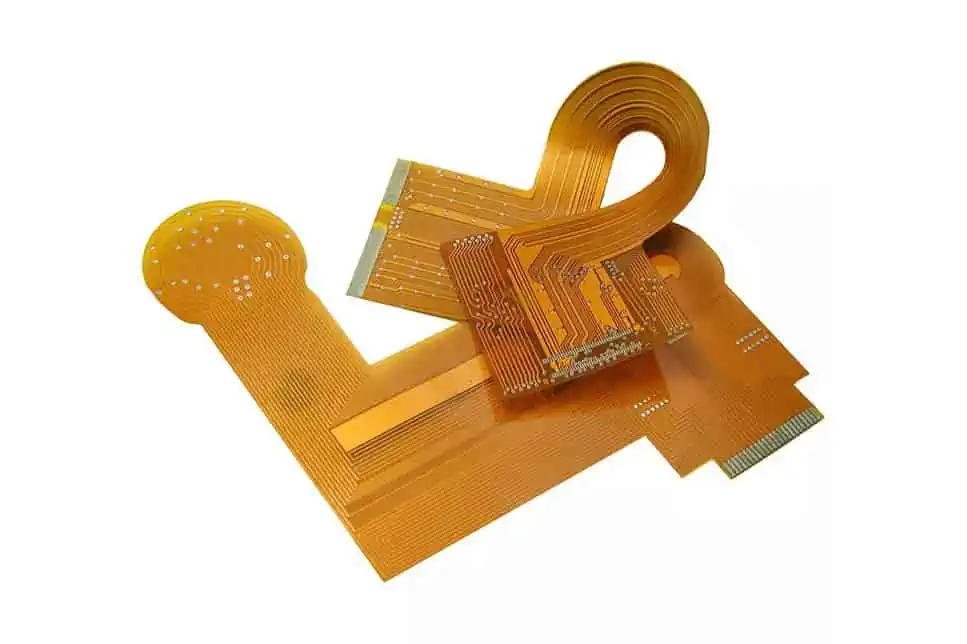

Iisekethe zeFlex ziza kwiindidi ezisibhozo, ukusuka kwi-single-layer ukuya kwi-multi-layer ukuya kwi-rigid. Nazi ezinye zeentlobo eziqhelekileyo zeesekethe eziguquguqukayo.

- Iisekethe ezibhetyebhetye kwicala elinye: Ezi sekethe zinomaleko omnye wobhedu phakathi kweeleya ezimbini zokugquma. Okanye umaleko omnye we-insulation (ngokuqhelekileyo i-polyimide) kunye necala elinye elingagqunywanga. Uyilo lwesekethe lufakwe ngokwekhemikhali kumaleko obhedu apha ngezantsi. Ngenxa yendlela ezenziwe ngayo, iikhomponenti, izihlanganisi, izikhonkwane, kunye nezinto eziqinileyo zingongezwa kwiibhodi zesekethe eziguquguqukayo ezinecala elinye.

- IiSekethe ezikwicala elinye eziFleksi ezinoFikelelo oluBini: Ezinye iiPCB eziguquguqukayo ezinecala elinye zinendlela evumela ukuba abaqhubi besekethe bafikelelwe macala omabini ebhodi. Ukusebenzisa i-PCB eguquguqukayo kunye neengqimba ezithile zalo msebenzi woyilo kwenza kube lula ukufikelela kumaleko obhedu omnye ngokusebenzisa umaleko we-polyimide wezinto ezisisiseko.

- Iisekethe ezinamacala amabini: Ezi zijikelezo ziguquguqukayo iibhodi zeesekethe eziprintiweyo ezinemigangatho emibini yokuqhuba. Ezi zijikelezo zohlulwe nge-polyimide insulation. Amacala angaphandle omgangatho we-conductive angavezwa okanye agqunywe. Uninzi lweemaleko ludityaniswe ngokufakwa kwimingxuma, kodwa kukho ezinye iindlela. Njengeenguqulelo ezisecaleni elinye, iiPCB eziguqukayo ezinamacala amabini zinokubamba iinxalenye ezongezelelweyo njengezikhonkwane, uqhagamshelo, kunye nezinto eziqinileyo.

- IiPCB eziguquguqukayo ezinamaleko amaninzi. Ezi sekethe zisebenzisa iileya zokuqhuba eziguquguqukayo ezintathu okanye ngaphezulu ezinomaleko wokugquma phakathi ukuze zenze iisekethe ezimacala omabini kunye namacala amabini. Iileya zangaphandle zezi yunithi zihlala zinamagquma kunye nomngxuma ophumela ngaphandle. Zihlala zihlanganiswe ngobhedu kwaye ziqhube ubude bobunzima bezi zijikelezo eziguquguqukayo. Ngeesekethe eziguquguqukayo ezinamaleko amaninzi, unokunqanda ii-crossovers, intetho enqamlezayo, i-impedance, kunye neengxaki zokukhusela. Zininzi iindlela zokuyila iisekethe ezinamaleko amaninzi. Umzekelo, ii-vias ezingaboniyo nezingcwatyiweyo zinokukha iibhodi eziguquguqukayo ezinamaleko amaninzi njengoko i-FR4 inako. Kwakhona, unokulalisa iileyile zesekethe enamaleko amaninzi ngokuphindaphindiweyo ukwenzela ukhuseleko olongezelelweyo, kodwa eli nyathelo lidla ngokutsitywa ukuba ukuguquguquka kubaluleke ngakumbi.

- Iisekethe eziguquguqukayo eziqinileyo: Ezi PCB zahluke kancinane kunezinye, kwaye ngokuqhelekileyo zibiza ngaphezu kwezinye iinketho PCB bhetyebhetye, nangona bakhonza injongo enye. Amaxesha amaninzi, olu yilo lunemigangatho emibini okanye ngaphezulu eqhubayo, enokufakwa okuqinileyo okanye okuguquguqukayo phakathi komnye nomnye. Ngokungafaniyo neesekethe ezinamanqwanqwa amaninzi, zisebenzisa kuphela i-stiffeners ukugcina iyunithi kunye, kwaye abaqhubi babekwe kwiingqimba ezingenakuguquguquka. Ngenxa yoku, ii-PCB eziguquguqukayo eziguquguqukayo ziye zaziwa kwi-aerospace kunye namashishini okhuselo.

- Iibhodi zeAluminiyam eziguquguqukayo: Iibhodi zesekethe eziguquguqukayo ze-aluminium eziprintiweyo zisebenza kakuhle kumashishini afana namayeza kunye neemoto ezisebenzisa umbane kunye nokukhanya okuninzi. Kwaye ngenxa yokuba zincinci, ziyakwazi ukungena kwiingcango ezincinci. Olu lutyalo-mali olugqwesileyo kuba alunamali, lulula, kwaye luhlala ixesha elide. Kananjalo banamaleko e-aluminiyam anceda ubushushu buhambe phakathi kwabo.

- Iisekethi ezincinci: Iibhodi ze-microcircuit eziguquguqukayo zezona zisombululo ze-elektroniki zabathengi. Ngenxa yobunzima bazo kunye nokuchasana nokothuka kunye nokungcangcazela, ezi zixhobo zifanelekile kubathengi be-elektroniki. Iimicrocircuits zinophawu oluhle lwengqibelelo, ngoko ke ubungakanani bazo obuncinci abuchaphazeli indlela abasebenza kakuhle ngayo.

- Iibhodi ze-high-density interconnector (HDI) ezineesekethe eziguquguqukayo: Ezi zinenye yeetekhnoloji ezikhula ngokukhawuleza kwishishini lebhodi yesekethe eprintiweyo. Ngenxa yokuba baneengcingo ezininzi kuneebhodi zesekethe zemveli, baphucula ukusebenza kombane kunye nesantya ngelixa besenza izixhobo zibe lula kwaye zincinci. Basebenza kakuhle kwizixhobo ezifana neeselfowuni, iikhomputha, kunye nemidlalo yevidiyo.

- Iibhodi zesekethe ezithambileyo kakhulu, eziguquguqukayo eziprintiweyo: Ezi zineenxalenye ezincinci, ezincinci kunye nezixhobo zebhodi. Oku kubenza bagqibelele kwizinto zombane ezifuna ukuphatheka okanye zibekwe ngaphakathi emzimbeni. Okanye ngalo naluphi na olunye usebenziso olufuna iibhodi zesekethe ezilula kakhulu.

Izicelo zeFPCB

I-PCB eguquguqukayo iyafana nebhodi yesekethe eprintiweyo rhoqo, ngaphandle konxibelelwano lwesekethe, zenziwe ngezinto ezisisiseko eziguquguqukayo. Oku kuluncedo kakhulu kwizinto ezingafanelanga ukufakwa ngokusisigxina. IiPCB eziguquguqukayo zisetyenziswa kumashishini amaninzi nangakumbi kuba zihlala ixesha elide kwaye zithatha indawo encinci. Le ilandelayo yimizekelo embalwa yendawo kunye nendlela obu buchwepheshe bunokusetyenziswa ngayo:

- Ushishino lweemoto: Ziya zisanda iimoto zinezixhobo ze-elektroniki. Ke, kubalulekile ukuba iisekethe zikwazi ukuphatha amaqhuma kunye nee-jolts ezenzeka ngaphakathi emotweni. Ibhodi yesekethe eguquguqukayo eprintiweyo lukhetho lweshishini olubalulekileyo kuba lutshiphu kwaye luhlala ixesha elide.

- Consumer electronics: Iibhodi zesekethe eziprintiweyo eziguquguqukayo (PCBs) zihlala zisetyenziswa kwii-elektroniki zabathengi. Umzekelo, iiselfowuni, iitafile, iikhamera, kunye neerekhoda zevidiyo. Ukukwazi kwePCB ebhetyebhetye ukuphatha umothuko kunye nokungcangcazela kuya kuba luncedo ukuba ufuna ukuhambisa ezi zinto rhoqo.

- Usetyenziso lwedijithali olunesantya esiphezulu, iRF, kunye nemicrowave: IiPCB eziguquguqukayo zigqwesile kwi-high-frequency. Ungazisebenzisa kwi-high-speed digital, RF, kunye ne-microwave applications kuba zithembekile.

- Ii-elektroniki zemizi-mveliso. Ii-elektroniki zemizi-mveliso zifuna ii-PCB eziguquguqukayo ezinokufunxa ukothuka kwaye ziyeke ukungcangcazela kuba kufuneka zijongane noxinzelelo olukhulu kunye nokungcangcazela.

- I-LED: Ii-LED ziba ngumgangatho wokukhanyisa ezindlini nakumashishini. Itekhnoloji ye-LED yinxalenye enkulu yalo mkhwa kuba isebenza kakuhle. Uninzi lwexesha, ingxaki kuphela bubushushu, kodwa ukuhanjiswa kobushushu obulungileyo obuprintiweyo bebhodi yesekethe kunokunceda.

- Iinkqubo zonyango: Njengoko imfuno yokufakelwa kwe-elektroniki kunye nezixhobo zotyando eziphathwayo zinyuka. Oku kwenza uyilo lwe-elektroniki oluxineneyo noluxineneyo lubaluleke ngakumbi kwicandelo leenkqubo zonyango. Ungasebenzisa iibhodi zesekethe eziguquguqukayo eziprintiweyo kuzo zombini. Ngenxa yokuba unokuwagoba, kwaye anokumelana noxinzelelo lobugcisa botyando kunye nokufakelwa.

- Amandla ombane. Kwintsimi ye-electronics yamandla, ibhodi yesekethe eguquguqukayo eprintiweyo inenzuzo eyongezelelweyo yokuphatha imisinga ephezulu kuba ineeleyile zobhedu eziguquguqukayo kakhulu. Oku kubaluleke kakhulu kwishishini lombane wombane kuba izixhobo zifuna amandla angakumbi xa zisebenza ngokuzeleyo.

Ukubaluleka kweFPCB

Ungasebenzisa iibhodi eziguquguqukayo kakhulu kwiimeko eziguqukayo kunye nezizinzileyo kuba unokugoba. Xa kuthelekiswa neePCB eziqinileyo, unokolula iibhodi zesekethe ezisetyenziswa kwizicelo eziguqukayo ngaphandle kokwaphuka. Imilinganiselo ye-Borehole kwishishini leoli kunye negesi ilungile kuyilo lwesekethe eguquguqukayo. Ngenxa yokuba banokumelana nokushisa okuphezulu (phakathi kwe -200 ° C kunye ne-400 ° C), nangona iibhodi eziguquguqukayo zinomsebenzi wazo, awukwazi ukuzisebenzisa endaweni yeebhodi zeesekethe eziqhelekileyo. Iibhodi eziqinileyo zikhetho lwendalo kuba azibizi. Unokuzisebenzisa kwi-automated, usetyenziso lwevolyum ephezulu. Iibhodi zesekethe eziguquguqukayo yindlela yokusebenza, ukuchaneka, ukuchaneka, kunye nokugoba okungaguqukiyo.

Imicelimngeni kunye nokuqwalaselwa kweendleko zeFPCB

Xa usebenza neeFPCB, njengaxa uzama ukwenza utshintsho okanye ukulungisa, iingxaki zinokwenzeka. Udinga imephu entsha yesiseko okanye ubhale kwakhona isoftware ye-lithography ukutshintsha uyilo. Akukho lula ukwenza utshintsho kuba kufuneka uqale ukhulule ibhodi umaleko okhuselayo. Ubude nobubanzi bulinganiselwe ngenxa yobukhulu bomatshini abasetyenziselwa ukwenza. Kwakhona, ungazaphula ii-FPCBs ukuba uziphethe ngokungakhathali. Ke abantu abayaziyo into abayenzayo kufuneka basolder kwaye balungise.

Iindleko zihlala zingumba ophambili. Nangona kunjalo, isicelo sichaphazela kakhulu indlela i-FPCBs enexabiso ngayo xa ithelekiswa neePCB eziqinileyo. Kuba isicelo ngasinye seFPCB sahlukile, iindleko ezinxulumene noyilo lwesekethe yokuqala, uyilo, kunye neepleyiti zeefoto zibiza amanani amancinci.

Ii-FPCBs ekugqibeleni zinokufikeleleka ngakumbi kwimithamo ephezulu yokwenziwa ngenxa yeengcingo ezimbalwa, iziqhagamshelo, iintambo zocingo, kunye nezinye iindawo ezifunekayo ukuze zidityaniswe. Oku kuyinyani ngakumbi xa kujongwa uncedo olusuka phezulu nolusezantsi, olufana nokuncipha komngcipheko wekhonkco lonikezelo kunye nokuncipha kwezicelo zogcino oluziswa kubukho beendawo ezimbalwa.

Iimpawu eziphambili zeFPCB

Imboni yesekethe ye-flex iye yakhula ngesantya esizinzileyo. Ngenxa yolu kukhula, kubekho uphuculo olungakumbi kwitekhnoloji, efana nale:

- Imizobo eWalekeneyo: Imizobo eyalekeneyo ivumela abasebenzisi ukuba bathethe neesekethe ezingaphantsi kweePCB. Zizigqubuthelo ze-acrylic okanye zepolyester zeePCBs. Olu lwalekayo luhlala lunee-LED, iiLCDs, kunye nokutshintsha okuvumela abasebenzisi ukuba bathethe ne-PCB ngendlela abafuna ngayo.

- ISolder yeBha eshushu: Ungasebenzisa udibaniso lwe-solder eshushu endaweni yesinxibelelanisi ukudibanisa i-hardboard kunye nesekethe ye-flex. Isiphumo lunxibelelwano olungabizi kakhulu olunamandla kwaye luhlala ixesha elide.

- I-Laser Skived Slots kunye nemingxuma: Kwixesha elidlulileyo, Unokuzisika iiFPCB ngeencakuba. Kwaye umgangatho wokusikwa wawuxhomekeke kwindlela umntu anobuchule ngayo ekusebenziseni incakuba. Kodwa ngeelaser esinazo ngoku, sinokusika imigca ngokuchaneka okuninzi kunye nokulawula, okusivumela ukuba senze iisekethe ezincinci kwiiPCB eziguquguqukayo.

- Iphaneli: Iibhodi zesekethe, ezibizwa ngokuba ziiPCB, xa zidityanisiwe kwiiphaneli ezinkulu zeemodyuli ezininzi. Kwimigca yendibano "yokukhetha kunye nendawo". Oku kunokukhawulezisa inkqubo yokuhlanganisa iisekethe eziguqukayo ngobuninzi. Inyathelo lesibini kukwahlulahlula iiyunithi zibe ngamaqela amancinci.

- I-Adhesives-Sensitive Adhesives. Izinto zokuncamathelisa ezingevayo kuxinzelelo zincamathelisa izinto ngokukhupha iliner nokucinezela into kwiglu. Esi sixhobo sisoloko sisetyenziswa kwiibhodi zesekethe eziprintiweyo (PCBs) ukugcina iinxalenye zesekethe ngaphandle kokusebenzisa i-solder.

- Ishiyeli: Ngaphambili, ukuphazamiseka kwe-electromagnetic bekuyingxaki. Ibe yingxaki, ngakumbi kwiindawo apho i-elektroniki ichaphazeleka kakhulu yiyo. Oku akuyongxaki ngoku kuba iteknoloji yokukhusela iphucukile. Yanciphisa ingxolo kwaye yenza kube lula ukulawula ukuthintela kwemigca yesignali.

- I-Stiffeners: Ii-stiffeners ezenziwe ngezinto ezifana ne-FR4 kunye ne-polyimide zihlala zongezwa kwiisekethe eziguquguqukayo kwiindawo zokuxhuma. Amanqaku oqhagamshelwano apho isekethe ingasebenzisa inkxaso eyongezelelweyo. Ngenxa yoko, inkqubo iya kuhlala ixesha elide kwaye isebenze ngcono.

IiNzuzo zokusebenzisa iFPCB

Iteknoloji yeFlex PCB yenza kube nokwenzeka ukwenza iimveliso ezininzi ezintsha kunye noyilo. Ukonakala kwayo kuyafunwa kwiindawo zombane. Amalungu ombane afana noqhagamshelo, iingcingo, iintambo, kunye neebhodi zesekethe eziprintiweyo. Nazi ezinye zeenzuzo zokusebenzisa iisekethe eziguquguqukayo.

- IiFPCBs zisika ubunzima besixhobo malunga ne-70%.

- Banika iinketho ezininzi zokupakishwa kwe-elektroniki okungcono.

- IiFPCBs zikunceda ulungise iingxaki zokupakisha kunye neengcingo. Oku kungenxa yokuba ibhetyebhetye, iyaguquguquka, kwaye inokutshintsha imilo.

- IiFPCBs zinciphisa imfuno yeengcingo, uqhagamshelo, iibhodi zesekethe eziprintiweyo, kunye neentambo. Inceda ukusombulula ingxaki yendlela yokudibanisa izinto.

- Ukukwazi ukuvelisa iipakethi ze-3D zenziwa ukuba zikwazi ukuhambelana nezinto eziphathekayo kunye nobuncinci.

- Ukuhlanganiswa kombane: Kulula ukwenza izisombululo zesiko. Ikuvumela ukuba useke uyilo lwakho kwiindlela ezininzi zezinto eziphathekayo. Kwakhona, unokukhetha kwiindidi ezahlukeneyo zobuchule kunye nesitayile.

- Kungakhathaliseki ukuba ilungile okanye yomelele kangakanani i-heat sink yakho, isekethe eprintiweyo eguquguqukayo inokusingatha ubushushu. Ke, basebenza kakuhle kwiimeko zamandla aphezulu.

- Ii-FPCBs zibonelela ngokuphindaphindwa koomatshini kunye nombane.

- Baxabisa i-30% ngaphantsi kwe-wiring enzima yendabuko kunye nezinye iindlela zokuhlanganisa.

- I-FPCB idinga malunga nama-30% indawo encinane.

- I-FPCB inokuthenjwa ngakumbi kuba iimpazamo ze-wiring azinakwenzeka ngayo.

Iingxaki zokusebenzisa iFPCB

- Uyilo lokuqala lwesekethe yesekethe, iingcingo, kunye neenkosi zeefoto zibiza kakhulu. Ziyabiza kuba unokuzenzela kwisicelo ngasinye. Ii-Flexi-PCBs azibizi ndleko kusetyenziso oluphantsi.

- Iibhodi zeesekethe ze-flex zingumngeni wokubuyisela kunye nokulungiswa. Nje ukuba yakhiwe, kufuneka utshintshe iisekethe eziguquguqukayo ukusuka kuyilo lokuqala okanye inkqubo yokuzoba ukukhanya. Umphezulu unomaleko okhuselayo onokuthi uwususe ngaphambi kokuba ulungiswe kwaye uphinde uwubuyisele emva koko.

- Ngenxa yokuba zincinci, iibhodi zesekethe eziguquguqukayo eziprintiweyo azifane zisetyenziswe. Ngoko ke ukuveliswa kwabo ngokuqhelekileyo kwenziwa kwiibhetshi. Ngenxa yemilinganiselo yobungakanani bomatshini osetyenziswayo ukuzenza, awukwazi ukuwenza abe made kakhulu okanye abe banzi.

- Kulula ukuyonakalisa isekethe eguquguqukayo ngokuyisebenzisa ngokungakhathali, kwaye umonakalo unokwenzeka ukuba awumiselwanga ngokufanelekileyo. I-Soldering kunye nokusebenza ngokutsha kufuna abasebenzi abanezakhono ngenxa yoku.

Umahluko phakathi kweePCB ezingqongqo kunye neePCB eziguquguqukayo

Xa abantu abaninzi becinga ngebhodi yesiphaluka, bafanekisela ibhodi yesekethe eprintiweyo (PCB). Ngaphezulu kwesiseko esingaqhubekiyo. Ezi bhodi zidibanisa iindawo zombane kunye neengoma zokuqhuba kunye nezinye iindawo. Iglasi isoloko isetyenziswa njengezinto ezingeyo-conductive substrate zebhodi yesekethe eqinileyo. Ngenxa yokuba yenza ibhodi yomelele kwaye yomelele, ibhodi yesekethe eqinileyo inokugcina izinto zingashushu kakhulu ngenxa yoyilo lwayo oluqinileyo. Unokwenza iibhodi zeesekethe zemveli zezinto ezinzima ezifana nobhedu okanye i-aluminium. Kodwa unokwenza iiPCB eziguquguqukayo ekulula ukuzigoba, njenge polyimide. Iisekethe eziguquguqukayo zinokufunxa umothuko, ziyeke ubushushu obongezelelweyo, kwaye zithathe uluhlu olubanzi lweemilo kuba unako ukugoba. Ngenxa yokuba zenziwe ukuba zibe bhetyebhetye, iisekethe eziguquguqukayo zisetyenziswa ngakumbi nangakumbi kwizinto ezincinci zombane zanamhlanje. Kukho umahluko omkhulu phakathi kweebhodi zesekethe eziprintiweyo (PCBs) kunye neesekethe eziguqukayo.

- Ngenxa yokuba i-copper e-annealed rolled iguquguquka ngakumbi kune-electro-deposited copper, ungayisebenzisa njengento eqhubayo kwiisekethe eziguquguqukayo endaweni yobhedu olufakwe kwi-electro.

- Kwimveliso, ungasebenzisa i-overlay endaweni ye-mask solder. Ungayenza ukukhusela i-circuitry evezwe kwi-PCB eguquguqukayo.

- Nangona iisekethe eziguquguqukayo zibiza kakhulu, iibhodi zesekethe eziqinileyo azibizi kakhulu. Kodwa ngenxa yokuba iisekethe eziguqukayo zincinci, iinjineli zinokuzisebenzisa ukwenza izixhobo zabo zibe zincinci. Bayonga imali ngeendlela ezingabonakaliyo.

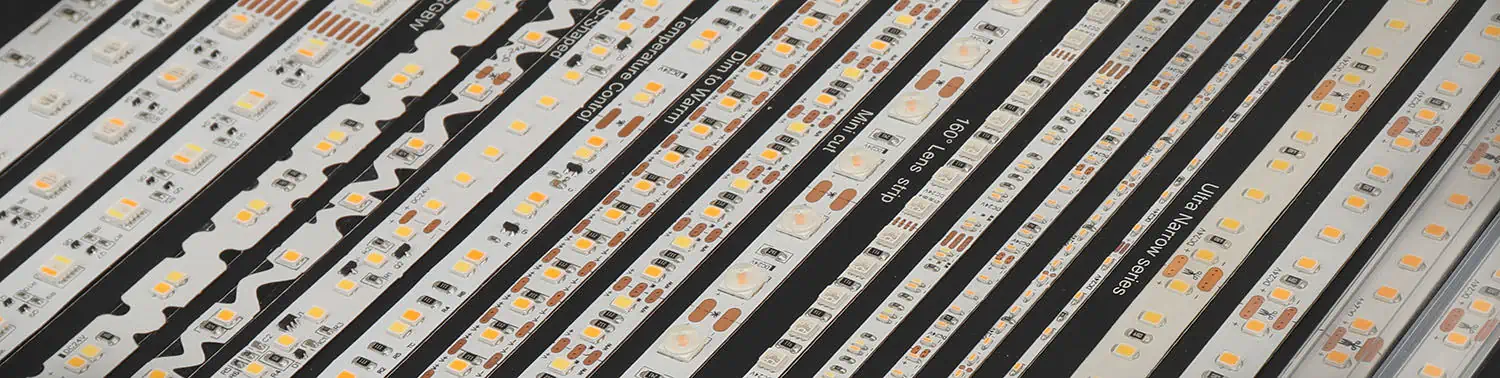

Ukubaluleka kweFPCB Kwimicu ye-LED

Njengoko iteknoloji iphucula, Imichilo ye-LED ziya zithandwa ngakumbi. Imicu ye-LED sele iyindlela entle yokukhanya kunye nokuhombisa ikhaya lakho, kwaye iPCB ebhetyebhetye iphucula izinto kuphela. Imichilo ye-LED ziibhodi zeesekethe ezidityaniswe omnye komnye. I-SMT (i-Surface Mount Technology) isetyenziselwa ukwenza iibhodi zeesekethe eziprintiweyo eziguquguqukayo (PCBs) ezineengxenye ezifakwe phezulu (ii-SMD LED, izixhumi, njl.). . Xa iitshiphusi ze-LED zihlanganiswa, i-FPCB isebenza njengesiseko kubo. Okubaluleke njengobume bebhodi yesekethe yindlela enokuthi ikhuphe ngayo ubushushu. Ii-elektroniki eziguquguqukayo ziluncedo olukhulu xa kufikwa kwizibane ze-LED strip. Njengee-PCB eziqinileyo, ii-FPCB ezahlukeneyo zine-single-layer, i-double-layer, kunye ne-multi-layer PCB circuits.

FAQs

I-Flexible PCB yindlela yokuhamba xa ufuna ibhodi yesekethe enokuthi ithathe nayiphi na imilo. Zihlala zisetyenziswa apho kufuneka ugcine ubuninzi kunye nobushushu obungaguqukiyo. Kuyilo lwe-flex, ungasebenzisa i-polyimide okanye ifilimu ye-polyester ebonakalayo njenge-substrate. Ezi zixhobo ziyakwazi ukuphatha ukushisa kakuhle kwaye zifanelekile kumacandelo e-solder.

- Fumana ifilimu eqatywe ngobhedu. Fumana amaphepha epolyimide abhityileyo njengephepha kwaye anobhedu kwicala elinye okanye omabini.

- Shicilela usebenzisa i-inki eqinileyo. Fumana umshicileli nge-inki eqinileyo ukuze uprinte kwifilimu yobhedu.

- Shicilela kwiPyralux

- Yifake.

- Beka iziqwenga ebhodini.

- IiPCB ezikwicala elinye.

- IiPCB ezinamacala amabini.

- IiPCB ezininzi.

- IiPCB eziqinileyo.

- IiPCB zeFlex.

- I-Rigid-Flex PCBs.

Ungasebenzisa ii-FPCBs kuzo zonke izinto zombane, ezifana nekhaltyhuleyitha, iiselfowuni, iiprinta, kunye noomabonakude beLCD. Iikhamera. Ungazisebenzisa kwizixhobo zonyango ezininzi, njengeemonitha zentliziyo, izincedisi-ntliziyo, kunye nezinto ezincedisa ukuva. Unokuzisebenzisa kwakhona kwiingalo zerobhothi, koomatshini bokucwangcisa, iiskena zebhakhowudi, njl.

- Usetyenziso olongezelelekileyo lunokwenzeka kwizinto ezininzi kuwo wonke amashishini ngenxa yokuguquguquka.

- Ukwenyuka kokuthembeka ngenxa yethuba elisezantsi lokungaphumeleli koxhulumaniso lwengcingo

- ukunciphisa ubunzima kunye nobukhulu xa kuthelekiswa neebhodi eziqinileyo

- I-Flex PCBs ifanelekile kwiimeko ezinzima ngenxa yoluhlu olubanzi lobushushu.

- Uxinaniso lweSekethe luphezulu

Ngokungafaniyo neePCB zesintu, iisekethe eziguquguqukayo zihlala zineecores ezenziwe ngepolymer eguqukayo endaweni yefiberglass okanye intsimbi. Uninzi lweePCB eziguqukayo zenziwe ngefilimu yePolyimide (PI) njengesiseko sezinto zazo. Nasemva kokuba i-thermoset, ifilimu ye-PI isaguquguquka, okuthetha ukuba ayithambanga xa ishushu.

Uninzi lweePCB eziguquguqukayo ezinobunzima obuphakathi kwe-0.2mm kunye ne-0.4mm. Ibhodi yesekethe eprintiweyo (PCB) enomaleko omnye inobunzima obumalunga ne-0.2 mm, ngelixa i-PCB enamaleko aphantse abe mane inobunzima be-0.4 mm.

Iindleko zokwenza i-PCB eqinileyo-flex iphezulu kune-PCB eqhelekileyo. Kodwa kulula ukuyidibanisa kwaye ifuna i-soldering encinci kunye nebhodi-to-board connectors. Ngenxa yoku, iindleko zokwenza inkqubo okanye imveliso yakho ziya kuncipha, ngakumbi ukuba indawo incinci.

Iibhodi zesekethe eziprintiweyo (PCBs) zinokuba ngqongqo okanye zibhetyebhetye. Badibanisa iindawo ze-elektroniki zezixhobo ezahlukeneyo zabathengi kunye nezingezona zabathengi. Njengoko igama layo libonisa, ibhodi yesekethe eprintiweyo eqinileyo (PCB) inomaleko wesiseko ongenakugoba. Kodwa unokugoba, ujije, kwaye usonge iiPCB ezibhetyebhetye.

Isekethe eprintiweyo luhlobo lwesixhobo sombane apho uprinta iingcingo kunye namanye amalungu njengomaleko obhityileyo wemathiriyeli eqhubayo phezu kwe-substrate ekhuselayo usebenzisa enye yeendlela ezininzi zobugcisa begraphic.

- Uvavanyo lwesekethe

- Uvavanyo lophando olubhabhayo

- Uhlolo oluzenzekelayo lwamehlo (AOI)

- Uvavanyo lokutshisa

- Ukuhlolwa kwe-X-Ray

- Uvavanyo olusebenzayo

- Olunye uvavanyo olusebenzayo (ukuthengiswa, ukungcoliseka, kunye nokunye)

- Izixhobo zoNyango.

- Ii-LEDs.

- Ii-Elektroniki zabathengi.

- Izixhobo zoShishino.

- Amacandelo ezeMoto.

- Izixhobo ze-Aerospace.

- Izicelo zaseLwandle.

- Izixhobo zoKhuseleko noKhuseleko.

- IiPCB zeFlex ziyabiza ekuqaleni.

- Ii-FPCs kunokuba nzima ukuzilungisa kunye nokutshintsha:

- Ubungakanani obulinganiselweyo

- Kusesichengeni ukonakaliswa:

Unokubonakalisa isekethe ye-flex ngemigangatho emibini okanye ngaphezulu yobhedu.

Zingaphi iileya ze-PCB ezifunekayo zisekelwe kwinani lezikhonkwane kunye neempawu zomqondiso. Ngoxinaniso lwe-pin ye-1, udinga iileya ezimbini zesignali. Inani leeleya ezifunekayo liyenyuka njengoko ukuxinana kwephini kusihla. PCBs kufuneka ubuncinane ezilishumi umaleko xa izikhonkwane nganye square intshi ingaphantsi kwe 0.2.

Ukuze uninzi lwezi zixhobo zisebenze, zifuna iimpawu ezinamandla. Nge-7-layer PCB, ungagcina cross-intetho kunye EMI encinane. Ngenxa yoko, ilungile kakhulu kwiinkqubo ezinje. Ungafumana iPCB enamaleko asixhenxe kwikhompyuter entsha.

Nangona iiPCB ezinezintlu ezintathu zinokwenzeka. IiPCB ezinomaleko-ntathu azifane zisetyenziswe ngenxa yokuba iiPCB ezinezintlu ezine zinokwenza yonke into enokwenziwa yi-PCB enemigangatho emithathu nangaphezulu.

I-PCB ye-2-layer yibhodi yesekethe eprintiweyo kunye neengubo zobhedu kuzo zombini phezulu nasezantsi. Ikwabizwa ngokuba yiPCB enamacala amabini. Inxalenye ephakathi yebhodi yesekethe eprintiweyo yi-insulating layer kuba kulula ukuyisebenzisa kwaye inokubekwa kwaye ithengiswe kumacala omabini.

IiPCB ezinomaleko-mbini zineempawu ezimacala amabini ezinomaleko ongentla nasezantsi. Ngelixa ii-PCB ezinomaleko omane zinemigangatho emine.

Ezi maleko zintandathu zineempawu zemiqondiso, umhlaba (GND), kunye namandla. Umaleko wokuqala nowesithandathu kufuneka ube ngumaleko wemiqondiso. Ii-PCBs zokuqala ezine umaleko zinokusetwa ngeendlela ezimbini: ngamaleko emiqondiso emibini, umaleko omnye womhlaba, kunye nomgangatho omnye wamandla.

isishwankathelo

Ungagoba kwaye ubhengeze iiFPCs ukuze zilingane iimilo ezahlukeneyo kunye nobukhulu. Oku kwenza kube lula ukuyila kunye nokusetyenziswa. Awukwazi ukubeka iisekethe eziqinileyo ezisemgangathweni kwiindawo ezinobungakanani obungaqhelekanga, kodwa iisekethe eziguquguqukayo zingakwazi. Iisekethe eziguquguqukayo zithatha indawo encinci kwi-motherboard yesicelo. Ibenza bangabizi kakhulu kwaye bangabikho bulky. Ngokwenza uninzi lwazo zonke iindawo ezikhoyo, ulawulo olungcono lwe-thermal lwenza ukuba ubushushu obuncinci bufune ukushukunyiswa. Iisekethe eziprintiweyo eziguquguqukayo zinokuthenjwa kwaye zihlala ixesha elide kunePCB eziqinileyo, ngakumbi xa iisekethe zihlala zishukunyiswa okanye ziphantsi koxinzelelo lomatshini. Ii-FPCBs zithathe indawo yeendlela zonxibelelwano zemveli. I-FPCBs ithathe indawo yazo ngokusekwe kwiingcingo ezithengisiweyo kunye nezihlanganisi ezifakwe ngesandla ngenxa yobunzima bazo, iprofayile ebhityileyo, ukumelana noomatshini, ukomelela kubushushu obuphezulu kunye neearhente zomoya, kunye nokunganyangeki kwe-electromagnetic (EMI). Cinga malunga nokuba kunzima kangakanani ukudibanisa zonke izikrini, izilawuli, kunye neziboniso kwimoto yanamhlanje (ulawulo lokujikeleza, amaqhosha, njl. Bafuna uqhagamshelo olukhuselekileyo kungakhathaliseki ukuba isithuthi sihamba njani. Ii-FPCBs ziqinisekisa ixesha lokuphumla, ubomi benkonzo ende, kunye nokugcinwa okuncinci kushishino lweemoto.

I-LEDYi yenza umgangatho ophezulu Imichilo ye-LED kunye ne-LED neon flex. Zonke iimveliso zethu zidlula kwiilabhoratri zobuchwepheshe obuphezulu ukuqinisekisa owona mgangatho uphezulu. Ngaphandle koko, sinikezela ngeenketho ezinokwenziwa ngokwezifiso kwimigca yethu ye-LED kunye neon flex. Ke, kwiprimiyamu ye-LED strip kunye ne-LED neon flex, uqhagamshelane LEDYi NGOKUKHAWULEZA OKUDIBENE NOKUNGXAMA!