The common voltages of LED strips are 12VDC and 24VDC, and their prices are the same. When you are ready to purchase LED strips, you may have questions, what is the difference between 12VDC strips and 24VDC strips? Which one should I choose?

LEDYi generally provides both 12VDC and 24VDC LED strips. Under normal circumstances, the difference between a 12VDC LED strip and a 24VDC LED strip is not too big, as long as you choose the correct power supply.

If you need a shorter cut length, we recommend choosing a 12VDC LED strip. For the LED strip with the same LED quantity, the cut length of the 12VDC LED strip is half of that of the 24V LED strip. This gives you more flexibility to cut the LED strip to the length you want.

If you need a longer linear run and higher luminous efficiency, we recommend choosing 24VDC LED strips.

If you’re curious to learn more about the technical aspects, read below for more differences:

12VDC LED strip with shorter cut length

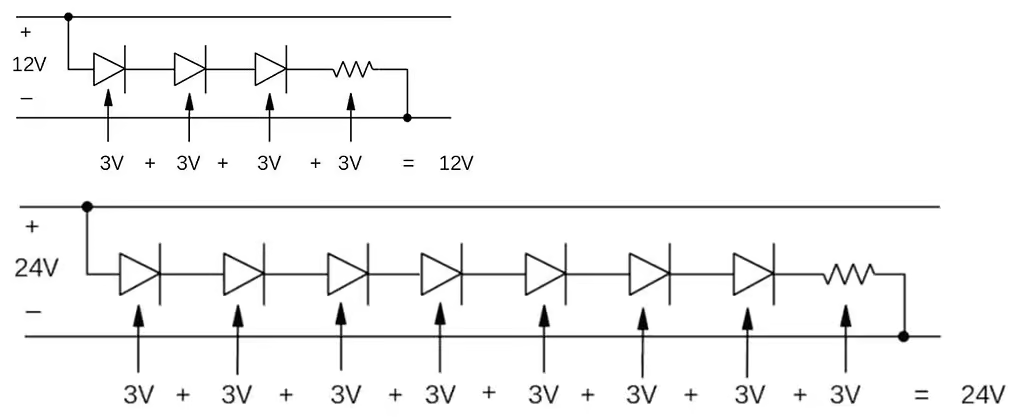

Most individual LED chips run on 3VDC power regardless of whether they are mounted on a 12V strip or a 24V strip. In fact, the same LED chip that works on a 12V strip could also be mounted on a 24V strip. What makes the difference is how the strip circuitry is designed.

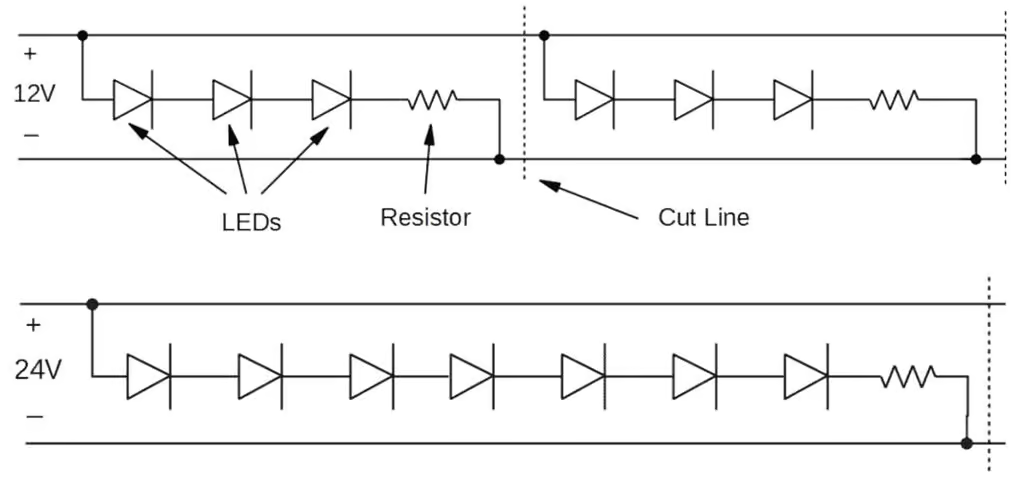

LED Strips are wired in groups of LEDs. The size of the

group depends on the voltage of the strip. A 12V strip has 3 LEDs, and a 24V strip has 6 LEDs or 7 LEDs, even up to 8 LEDs. The cut lines are located between the groups. Therefore, the smaller each group of LEDs, the closer together the cut lines can be.

For example, see the diagrams of 12V and 24V strips below:

A lower voltage 12VDC strip with closer cut lines may be good if your installation has many corners with short lengths. This can help to minimize the “dark” zone at the corners.

To get the advantage of the Long Run of the 24VDC LED strip and the shorter cutting length of the 5VDC LED strip, we have developed Mini Cutting LED Strip, 1 LED per cut at 24VDC.

12V LED strip has a wider range of application scenarios

On the other hand, 12 VDC is a common voltage, so LED strip compatibility may eliminate the need for additional power supplies. For example, if you are installing lights in a vehicle, a 12 VDC LED strip light can often be directly connected to the existing electrical system. While there are certainly exceptions to this, and it is important to check your existing system before making a purchase, 12V LED strips can offer a more convenient installation solution in many cases.

24V LED strip, longer linear run

A higher voltage strip will generally be able to have longer runs without suffering from the effects of voltage drop.

What is voltage drop?

Voltage drop causes LED strips to lose their intensity as they become longer. LEDs at the beginning of the strip (nearest the power supply) will shine brightly. In contrast, LEDs at the end of the strip will have a dimmed appearance.

Why does voltage drop happen?

Any length of wire has a certain amount of electrical resistance. The longer the wire, the more the resistance. Electrical resistance causes voltage drop, and voltage drop causes your LEDs to dim.

Therefore, LEDs at the end of a strip will always get less voltage than the ones at the beginning. If you make the strip long enough, the voltage drop will become significant enough to cause a visible difference in brightness.

How does higher voltage reduce the effects of voltage drop?

First, you have to understand how all the components on an LED strip are connected.

Most individual LED chips run on 3V DC power regardless of whether they are mounted on a 12V strip or a 24V strip. In fact, the same LED chip that works on a 12V strip could also be mounted on a 24V strip. What makes the difference is how the strip circuitry is designed.

LED chips are wired in series into groups. Each group contains some LED chips and a resistor. The total voltage drop across the group has to be equal to the total voltage of the strip (see diagrams below).

Then, each group is wired in parallel and arranged along the length of the strip.

For now, take notice (above diagrams) that the group size on a 24V strip is 7 LEDs compared to only 3 LEDs for 12V. I will explain why this is significant below.

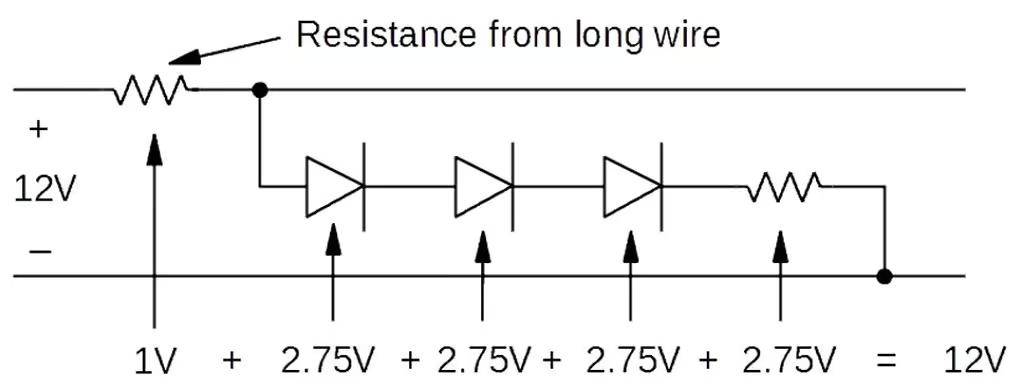

Every wire has a certain amount of resistance to electricity being pushed through it. The longer the wire gets, the bigger the resistance (and the voltage drop) gets. Eventually, it gets large enough to impact the LED brightness. Below is an example of how it might happen on a 12V strip.

Notice in the above diagram that the voltage across the LEDs has dropped from 3.0V to 2.75V.

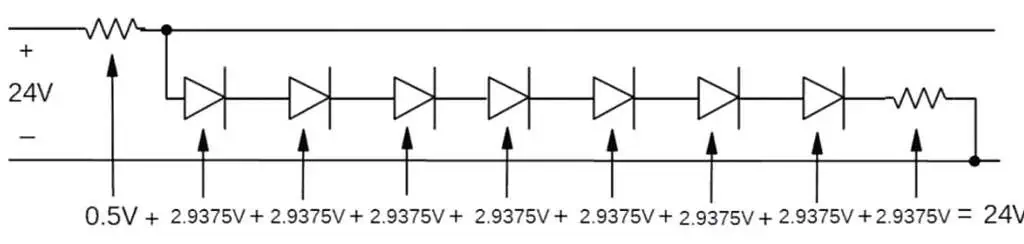

When we switch to 24V, two things happen that reduce the voltage drop.

When the voltage gets doubled (12V to 24V), the current is halved (Ohm’s law P=U * I). That causes the voltage drop from the long wire to be reduced by half as well. So instead of a 1V drop, it becomes 0.5V drop.

The effect of the 0.5V drop is split between the eight remaining circuit components (compared to 4 on the 12V).

Notice here that the voltage across the LEDs has only dropped to 2.9375V compared to 2.75V with the 12V strip.

If you have an application that requires long runs of strips, it may be a good idea to use 24V strips. But, even 24V strips have a limit. You may have to use other techniques to stop your LEDs from fading at the end. For example, use our Super Long Constant Current LED Strips.

24V LED strip can be higher efficiency

Higher voltage can be more efficient.

Any time there is the voltage across a resistor, it means energy is getting converted to heat instead of light. Therefore, the resistors in the above diagrams are necessary, but they’re also a source of wasted energy.

| Total voltage of strip | Voltage across resistor | % Power “wasted” on resistors |

| 5V (1 LED Per Group) | 2V | 40% |

| 12V (3 LEDs Per Group) | 3V | 25% |

| 24V (7 LEDs Per Group) | 3V | 12.5% |

It’s easy to see that higher voltage strips suffer from less wasted energy. LEDs use such a small amount of energy that this doesn’t add up to much for small installations. But, the difference in power usage can become significant for the whole room or commercial installations.

We have developed high-efficiency LED strips, 8 LEDs per cut, up to 190LM/w.

This is the same principle as high-voltage power transmission. The higher the voltage, the smaller the current. According to Ohm’s law, the voltage drop Vdrop=I * R, the electrical energy converted to heat P=U * I = (I * R) * I = I 2 * R.

24V LED strip requires less conductor gauge

Electrical power is determined by the equation P = V * I. To maintain the same power (P), if voltage (V) goes up, current (I) must come down by a proportional amount.

If we keep 48W as our target output as a concrete example, a 12V system will require 4 Amps (12V x 4A = 48W), while a 24V system will only require 2 Amps (24V x 2A = 48W).

Simply put, a 24V LED system will draw half the amount of current as a 12V LED system to achieve the same power level.

Why is this important?

Total current, rather than voltage, determines the thickness and width of copper conductors needed to transfer power safely.

If excessive amounts of current are forced through a small or narrow copper conductor, resistance inside the conductor will become significant and contribute to voltage drop and heat generation. In very extreme cases, this can even lead to electrical fires.

All else equal, a 24V LED system can get away with half of the electrical conductor requirements. You can use the voltage drop calculator to ensure you are still using sufficient conductor gauges for your LED strip projects.

Smaller power supplies for 24V LED strip

Like conductor size, power supply size is also determined primarily by current rather than voltage. Part of this is also influenced by the physics relationship between electrical current and conductor size needs, as much of a power supply unit’s internal wiring comprises copper wiring.

Power supply size can be important when working with projects such as LED strip lights in under cabinet installations where there may be space constraints.

Conclusion

I believe that after reading this article, you and I have come to the same conclusion that the advantages of 24VDC LED strips are far more than 12VDC LED strips. If possible, especially in large lighting projects, please use 24VDC LED strips.

LEDYi manufactures high-quality LED strips and LED neon flex. All of our products go through high-tech laboratories to ensure the utmost quality. Besides, we offer customizable options on our LED strips and neon flex. So, for premium LED strip and LED neon flex, contact LEDYi ASAP!